SLA 3D Printing

-

SLA Parts Fast

-

High-Quality Surface Finish for Prototype Models

-

Tight Tolerances & Fine Details

Trusted by Industry Leaders

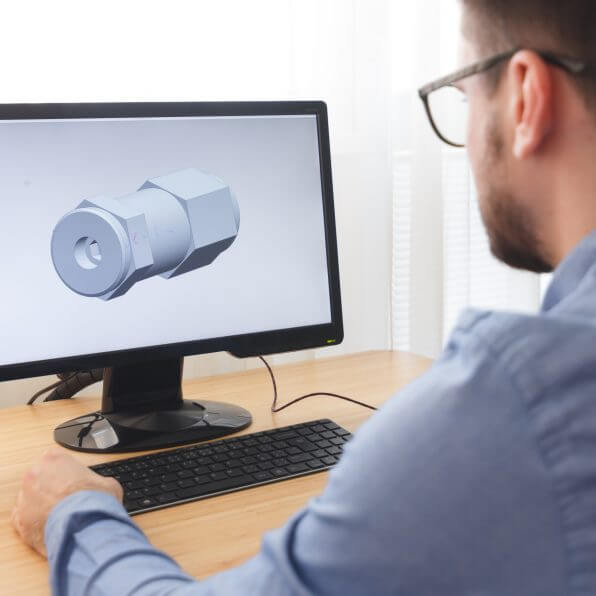

How Does Stereolithography (SLA) 3D Printing Work?

Is SLA Right For Your Application?

Advantages

-

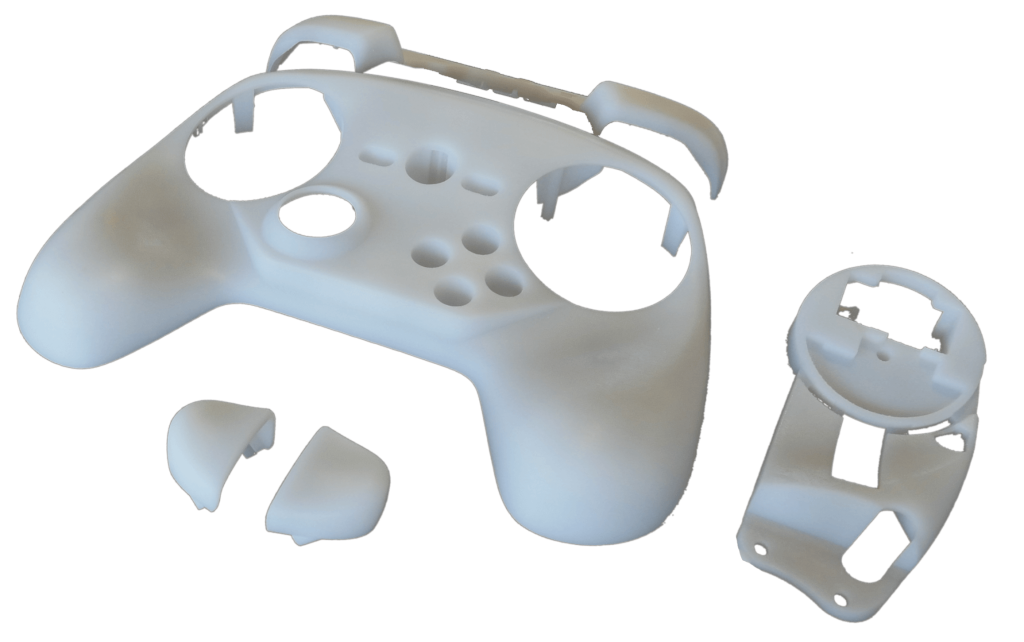

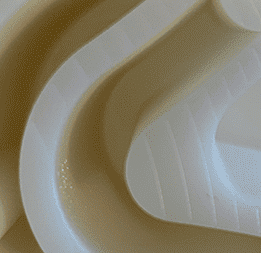

High-Quality Surface Finish

The excellent surface finish and dimensional accuracy of SLA prototype parts make them ideal for testing for fit and finish.

-

Clear Parts

Fathom’s SLA printing service can print parts using a clear resin which can be sanded to an optically clear finish that is almost glass-like in appearance.

-

Small Layer Size

SLA can print in layers as small as 0.002 inches. That enables it to produce very fine details and cosmetic-quality surfaces.

-

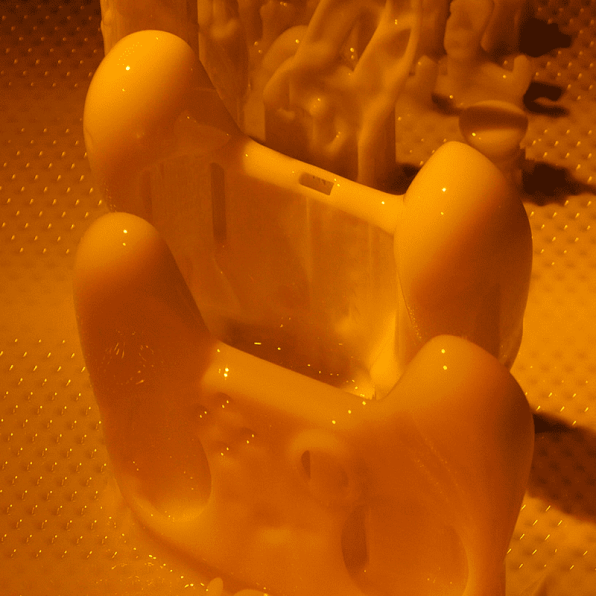

Print Complex Shapes

Thanks to its fine resolution (hundreds of microns), stereolithography 3D printing can be used to print thin walls, sharp corners, small holes and complex shapes.

-

Tolerances

SLA offers some of the tightest dimensional tolerances of any additive manufacturing technology.

-

Larger Prototypes

SLA enables the production of larger, lightweight prototype parts, using internal lattice structures for support.

-

Easy to Post-Process

Parts produced by Fathom’s SLA printing service are easy to finish by sanding, painting and/or clear coating.

Disadvantages

-

Sensitivity to UV Light

SLA parts are produced using photopolymers, which means they may become brittle over time when exposed to sunlight.

-

Not the Strongest Additive Technique

SLA parts are not always as robust as those produced using other thermoset or thermoplastic additive technologies. For that reason, they are not always recommended for functional components. Ask your industrial 3D printing service if SLA is the right additive process for your application.

-

Support Marks

SLA doesn’t offer the option of dissolvable supports. When supports are removed from parts, they may leave visible marks, which require post-processing to remove.

Optimize Your Design with SLA Material Insights

Get a clear view of material properties, tolerances, and best-fit applications for SLA. Perfect for teams who need tight detail, smooth surfaces, and reliable performance.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.