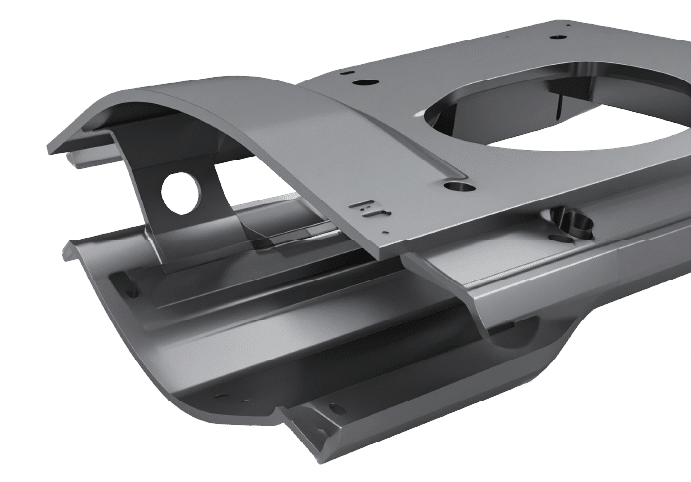

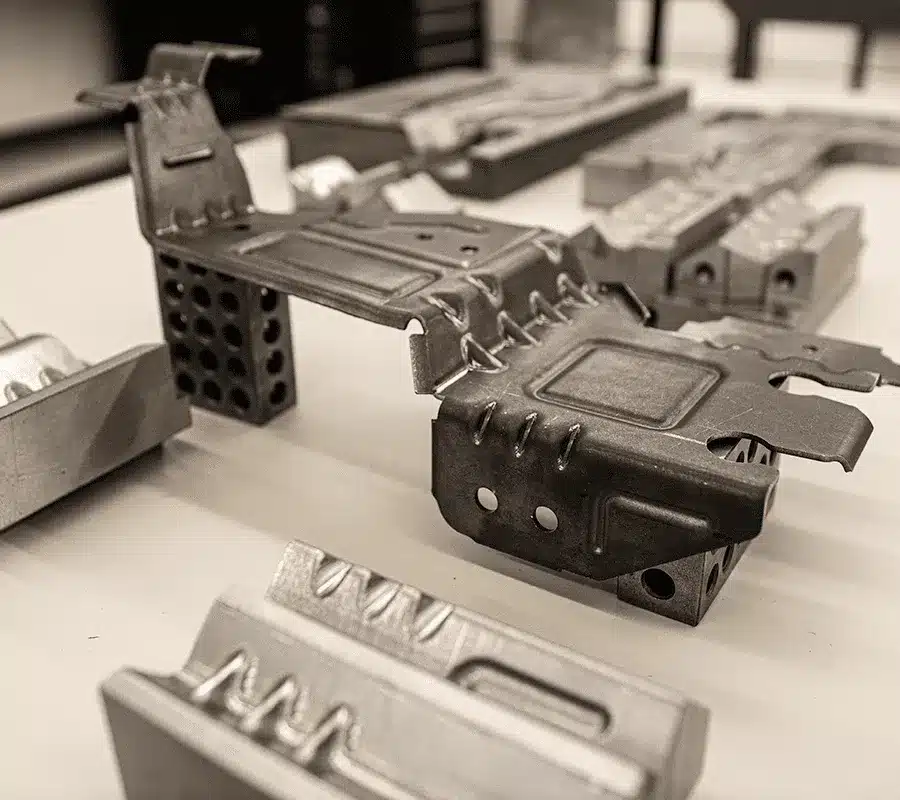

Q.

Why is it an advantage to work with a contract manufacturer that offers many types of cutting solutions?

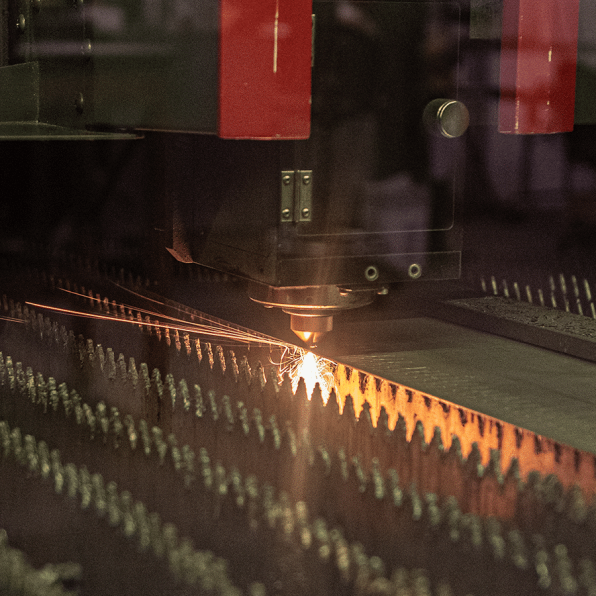

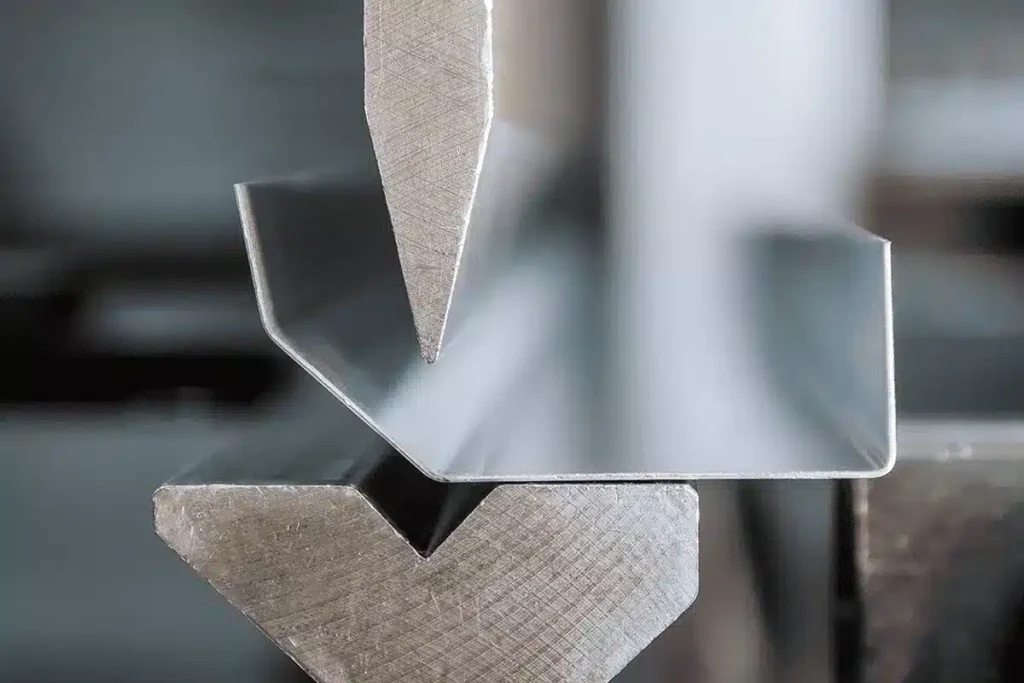

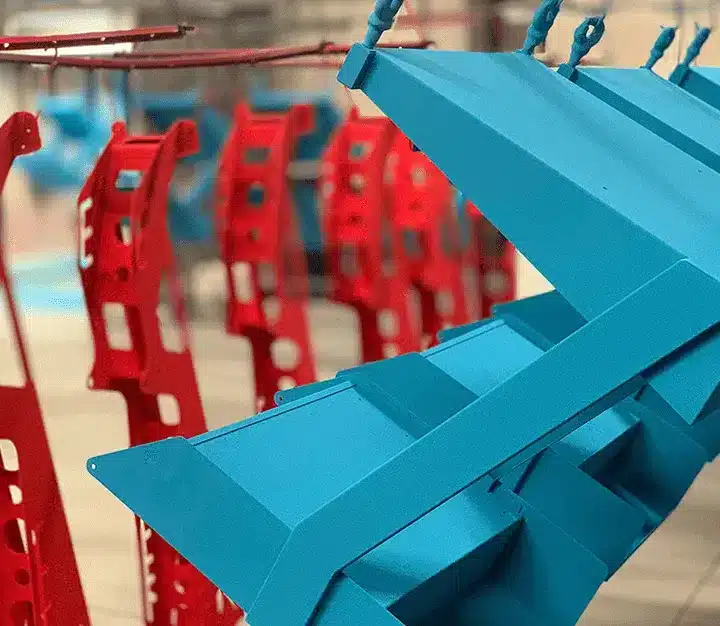

Fathom supports laser cutting, water jet cutting, micro water jet cutting, wire EDM, plunger EDM and photo chemical etching. Each technology has its own unique strengths and weaknesses. Our broad range of cutting solutions enable us to tailor our solutions to your precise needs.