Our Certifications

Kick Off Your Project Today

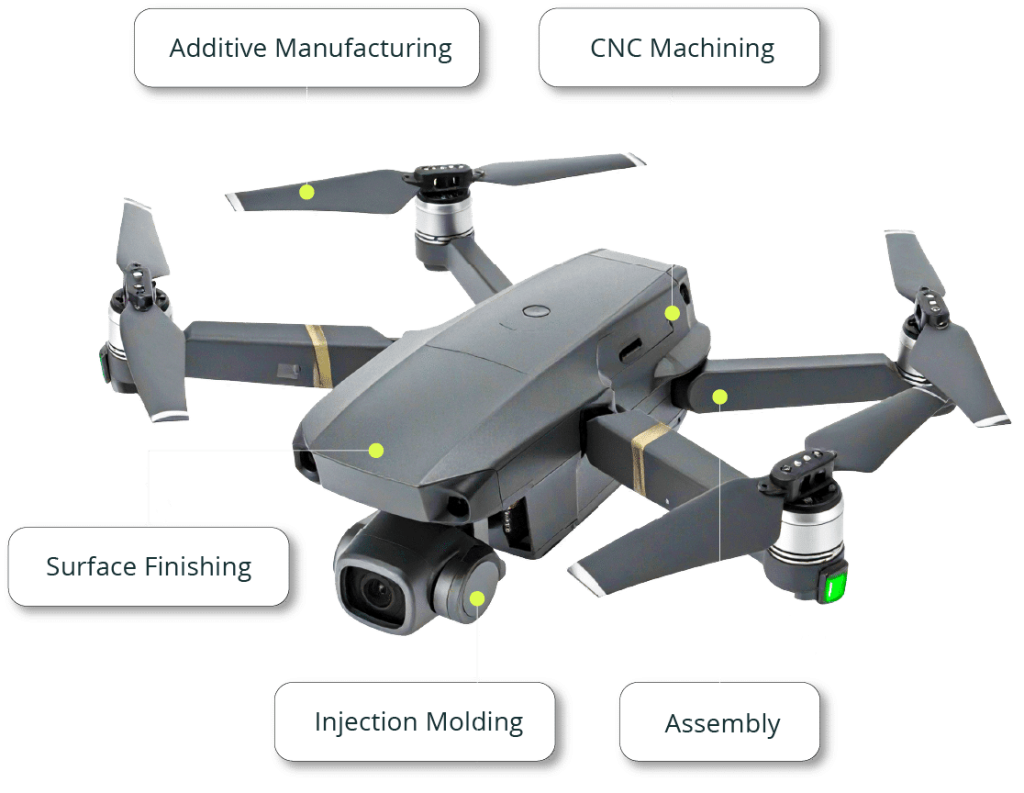

Expect More From Contract Manufacturing

It’s time to level up your expectations. Contract manufacturing should be much more than an automated quote and superficial DFM feedback. Experience the Fathom white-glove difference – an engineering and expertise-driven process that will guide you from concept to production with clarity, confidence, and zero guesswork.