MJF 3D Printing

-

MJF Parts As Soon As 2 Days

-

Cost-Effective for Short-Run Production and Prototyping

-

Complex Geometries with High Performance Materials

Trusted by Industry Leaders

How Does Multi Jet Fusion 3D Printing Work?

Advantages & Limitations of MJF

Advantages

-

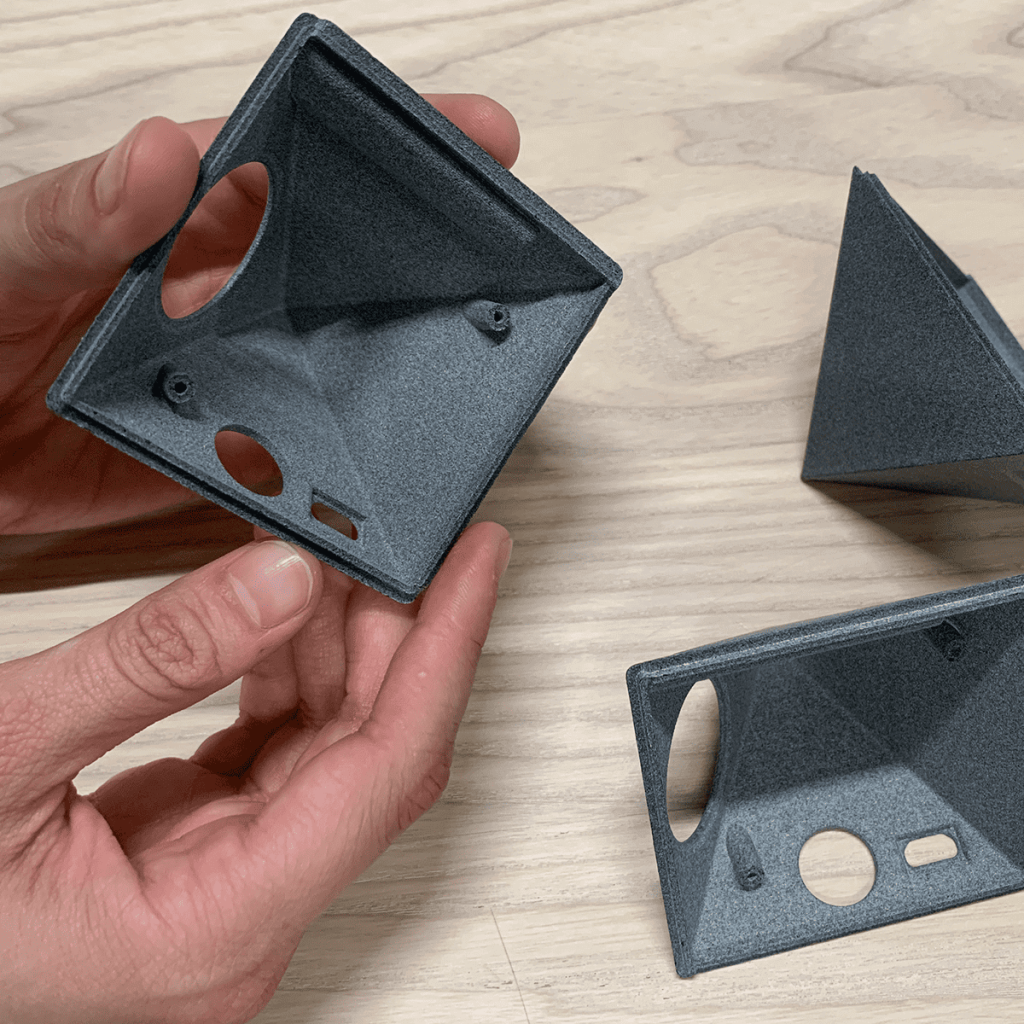

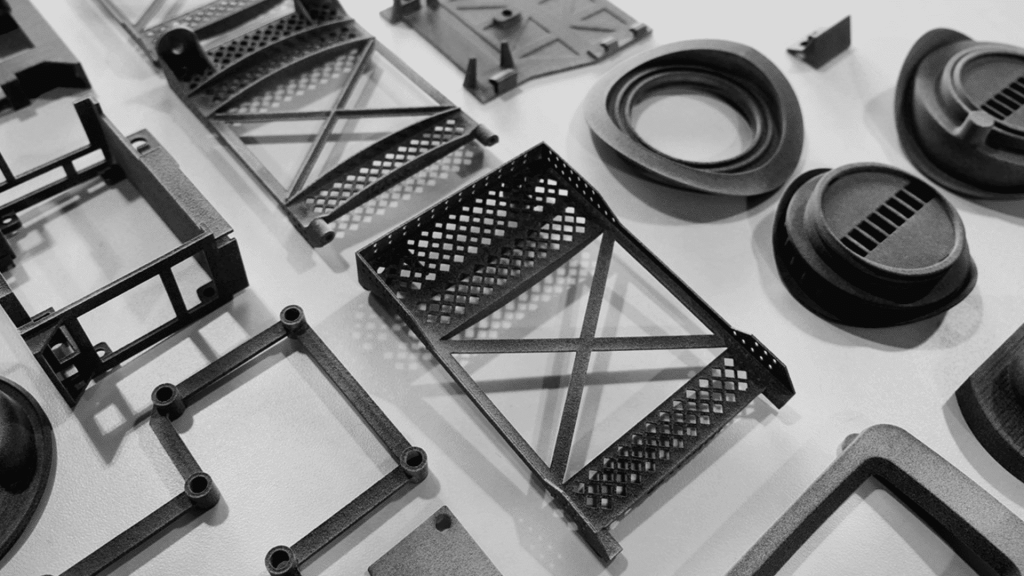

Complex Geometries

Fathom’s MJF printing service can be used to print highly detailed and dimensionally accurate parts. That makes it well-suited for producing functional prototypes and end-use parts with unique shapes.

-

Excellent Surface Finish

Because MJF uses a thin layer structure, it offers one of the smoothest surface finishes of any 3D printing technology.

-

Produce a Large Volume of Parts Quickly

Multiple parts can be produced at the same time in a single build.

-

Excellent Mechanical Properties

Parts produced using MJF have excellent isotropic mechanical properties.

-

Removable Build Volumes

Parts and their build platform can be removed from the printer for cooling. Meanwhile, another build volume can be installed so the printer can begin producing more parts. This unique design enables high-volume production of parts.

-

More Sustainable

Up to 80% of the powder from MJF prints can be recycled in subsequent prints, more than with SLS.

Disadvantages

-

Limited Material Selections

Because MJF is a process that’s proprietary to HP, you’re restricted to their materials – Nylon 11 and 12.

-

Limited Color Options

Parts produced with MJF have a dark gray color, which limits your ability to recolor them.

-

Avoid Long & Thin Part Features

They are susceptible to non-uniform cooling, which may cause warpage.

Unlock High-Strength, High-Throughput MJF Materials

Review material specs, durability profiles, and design considerations for Multi Jet Fusion. Build parts that balance speed, strength, and repeatable performance at scale.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.