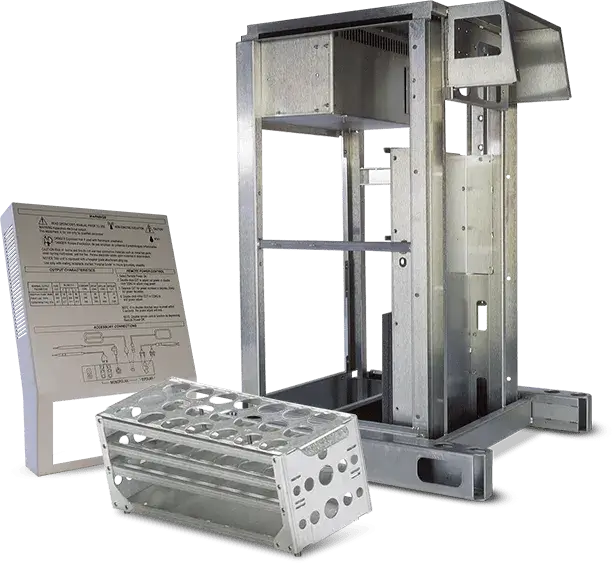

Large-Format Sheet Metal Fabrication

-

Extensive Capabilities from Prototype to Production

-

Decades of Sheet Metal Fabrication Expertise

-

Simplify Your Supply Chain

Trusted by Industry Leaders

How Does Large Format Sheet Metal Fabrication Work?

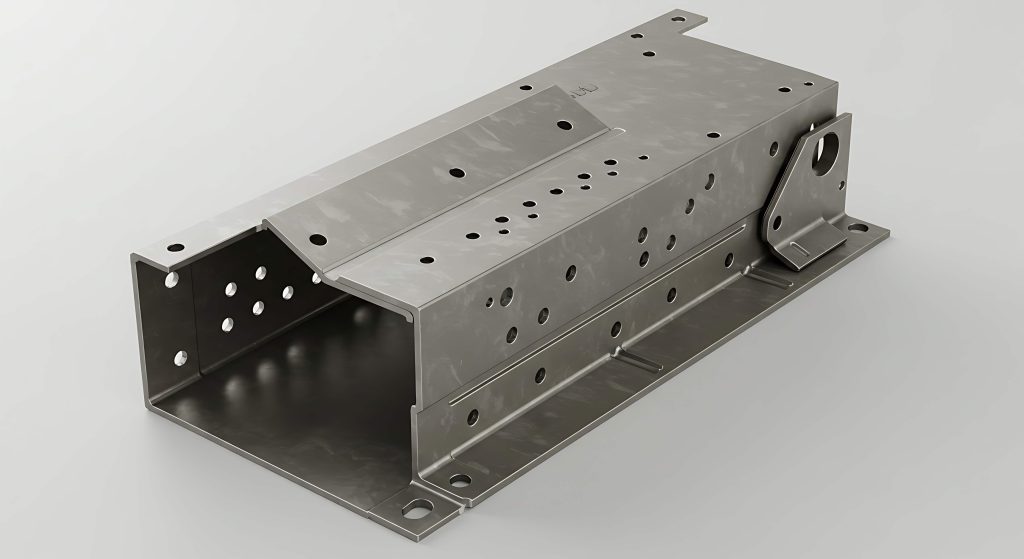

Large sheets of metal are first cut into blanks in the shape of the finished component. These may be cut using laser cutting or water jet cutting. Laser cutting is faster but may cause heat-affected edges. Water jet cutting is slower but doesn’t affect the physical characteristics of the metal adjacent to the cut. These tools follow instructions from the 3D CAD drawing of the part. Holes may also be punched into the sheet metal as required by the part design.

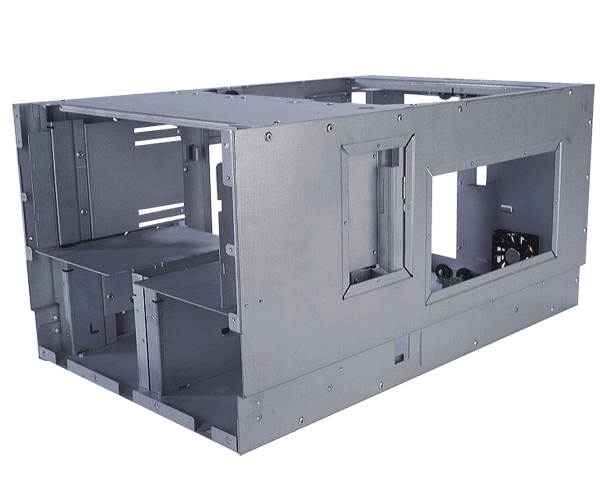

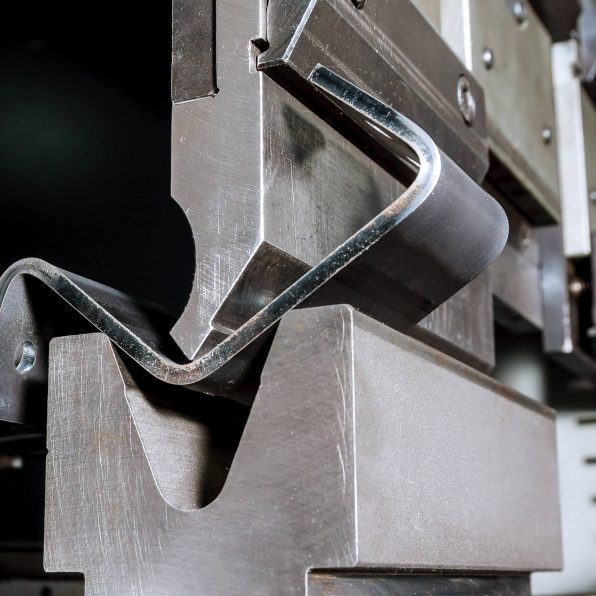

Large devices called press brakes are used to make bends in the metal to shape it. A press brake consists of a punch and a die. The sheet metal is placed between them. The punch then presses the sheet metal into the die, bending it into the desired shape. Custom tooling may also be used to form special shapes. Sheet metal forming is used to make brackets, enclosures, auto parts and other types of large components.

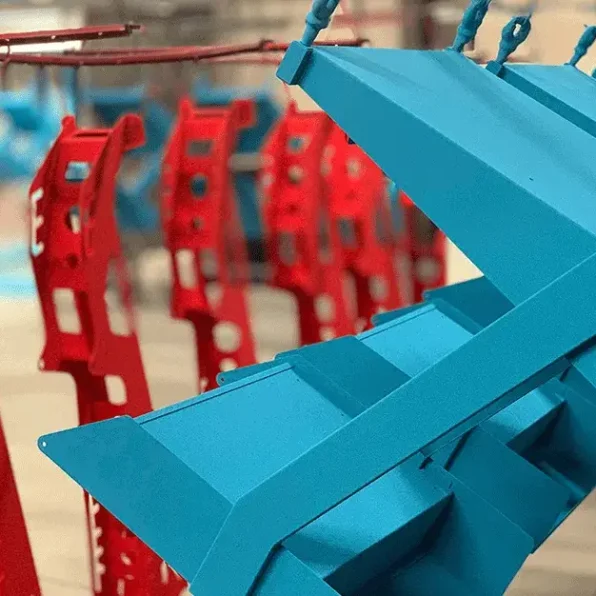

Common post-processing steps for large sheet metal fabrication including deburring sharp edges left by cutting or punching processes, anodizing, electroplating, polishing and laser marking. Assembly steps may include welding, riveting or adhesives to join components into an assembly. Sheet metal offers multiple finishing options that we use to enhance its appearance and protect it from corrosion. They include painting, powder coating and anodizing.

Advantages & Disadvantages of Large Sheet Metal Fabrication

Advantages

-

Customization

Because sheet metal is easy to work with, we can build custom metal parts that meet your precise requirements.

-

Affordable

Compared to machining, sheet metal fabrication is much less expensive and provides flexibility during each step of the fabrication process.

-

Accurate

Metal parts are cut to precise sizes and shapes using computer-controlled equipment. This minimizes the need for secondary processes such as grinding and polishing.

-

Scalability

Sheet metal forming accommodates production changes without big investments in retooling. This makes it well-suited for creating prototypes and small batches of parts for testing and validation. It’s also a cost-effective way to produce production parts in small to medium-sized quantities.

-

Short Lead Times

Sheet metal fabrication doesn’t require many processing steps. That’s why its lead time is often shorter than other manufacturing technologies. This makes it a popular option for sheet metal prototyping.

-

Aesthetic Appeal

Sheet metal offers multiple finishing options that we use to enhance its appearance and protect it from corrosion. They include painting, powder coating and anodizing.

Disadvantages

-

Overhead Costs

Many metals require additional finishing processes, such as deburring or painting after fabrication. That can increase production time and overhead costs.

-

Design Limitations

Sheet metal must have a uniform material thickness. Corners are created by bending metal. That’s why they must have minimum radii equal to the material thickness. Some bends may require relief notches to prevent unwanted deformation. Holes and tabs can’t be located too close to bends. Otherwise, bulges may occur. And there are some limitations on where you can locate welds to hold parts together.

Industry Applications

Many industries choose Fathom for its sheet metal fabrication services, including medical, defense, aerospace, electronics, automotive and industrial companies. No matter what the industry, our team can meet the technological and manufacturing challenges your project demands.

Aerospace

Aerospace parts often require high accuracy and tight tolerances. Our team delivers parts for the aerospace industry that are durable, reliable and meet exacting specifications.

Automotive

Every finished part that departs our facilities will meet the rigorous standards of the automotive industry. You can rely on Fathom for sheet metal parts that are both reliable and safe.

Defense

The defense industry requires high precision and efficiency standards for weapons, vehicles, and more. Fathom is an ITAR registered manufacturer and defense contract supplier who can support all your military and defense needs for sheet metal components.

Electronics

The electronics industry requires parts with tighter tolerances and finer surfaces. Whether your electronics project needs a simple or complex design, Fathom delivers.

Industrial

Parts for industrial applications must be reliable and durable. Using our all-in-one manufacturing services, we can assist you from design to finishing your sheet metal parts.

Life Sciences

The medical industry sets high standards for both quality and cleanliness. Sheet metal fabrication is used to make a variety of medical devices.

Design Sheet Metal Components with Precision

Learn best practices for bends, features, tolerances, and material selection to streamline fabrication and improve part quality. Great for engineers looking to reduce costs and improve manufacturability.

Traditional Technologies That Can Benefit from Sheet Metal Fabrication

Sheet metal is inexpensive compared to other materials. It’s easy to work with and enables us to produce large quantities of precision-cut and formed parts quickly and affordably.

For enclosures and architectural details, there’s no substitute for large sheet metal fabrication. Because it gives you such a high level of control at every step of the fabrication process, it’s a cost-effective solution for both prototyping and production.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.

Additional Resources

Why Choose Fathom for Large Format Sheet Metal Fabrication

-

We’ve been helping customers solve their sheet metal fabrication challenges for decades.

-

We’re experienced problem-solvers. We’ll work closely with you to develop the most cost-effective and efficient solutions for your needs.

-

We offer domestic and overseas injection molding services that can grow with your needs.