Photochemical Etching

-

Ideal for Permanently Marking Flat Metal Parts

-

Can be Integrated into the Machining Process

-

Ideal for Part Tracking & Identification

Trusted by Industry Leaders

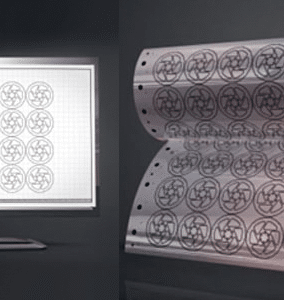

How Photochemical Etching Works

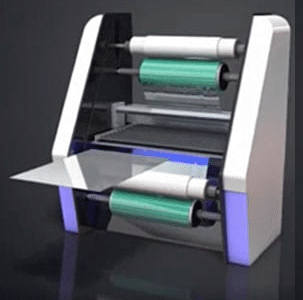

A metal sheet is cleaned and coated with a photosensitive material called a photoresist. A high-resolution mask is created from a CAD drawing of the desired part, which includes any markings such as logos or part numbers. Photoresist-coated metal is exposed to UV light through the photo tool. The light hardens the photoresist in the exposed areas, while the unexposed areas remain soft.

The soft, unexposed photoresist is removed during a developing process, leaving the metal beneath it exposed. The metal sheet is then sprayed with a chemical etchant, such as ferric chloride, which dissolves the exposed metal areas but does not affect the hardened photoresist. Marking is done by half-etching the metal. This creates a permanent, recessed mark that is integral to the part itself, without compromising the material’s integrity.

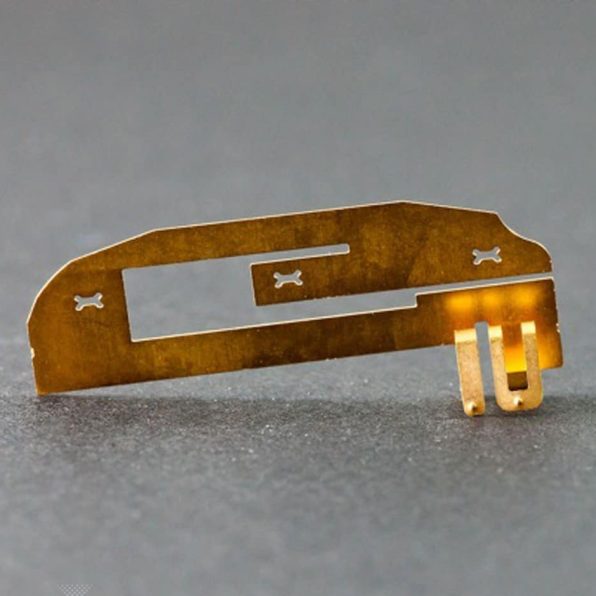

Once the metal has been etched to the desired shape, the remaining photoresist is stripped from the part. This leaves a precisely shaped, burr-free metal component. Secondary operations, such as forming or plating, can be performed afterward. In many cases, the photochemical machined blanks are shipped to Icodema by Fathom for forming and post-processing.

Is Photochemical Etching Right For Your Project?

Advantages

-

Fast Delivery

Because no hard tooling is required, we can fulfill many orders within a few days. Complex part designs may take up to a week. Photo chemical etching produces multiple parts from a single sheet of metal. Little or no finishing is required.

-

No Changes to the Integrity of the Metal

Many types of manufacturing, such as machining and laser cutting, can cause thermal stresses in the metal adjacent to the cut. They can also cause changes to the hardness, ductility or grain structure of the metal. Chemical milling doesn’t affect the internal structure of the metal.

-

Build Complex Yet Affordable Flat Parts

Industrial chemical machining enables you to create parts with fine details and complex geometries that aren’t possible to make using hard tools. You can also use it to fabricate parts in dead soft or full hard material without burrs or metal distortion.

-

Low-Cost Tooling

We produce films for photochemical machined parts directly from your CAD drawings. No hard tools or work-holding fixtures are needed. That helps to maximize the cost-effectiveness of photo chemical etching.

-

Easy, Fast & Inexpensive Prototype Parts

Photochemical machining uses films to create parts. That means you can iterate your designs quickly and affordably. The same process we use to create prototype parts is used to make your production parts.

-

Burr-Free Parts

Burrs are a common side effect of many types of metal processing. In contrast, the etching process produces a clean, smooth surface. It’s free of burrs and eliminates the need for manual finishing processes.

Disadvantages

-

Only For Thin Metal Parts

Photochemical machining is limited to relatively thin metals (1.5 mm or less)

-

Some Dimensional Inaccuracies

The etchant can sometimes undercut the edges of holes, leading to dimensional inaccuracies.

-

Only For Fabricating Flat Parts

Photochemical machining is a 2D process. It cannot be used to produce 3D parts.

-

Process Variables Must be Strictly Controlled

Inconsistent results can occur if process variables fluctuate, including etchant concentration, temperature or agitation.

-

Only For Marking New Parts

Photochemical etching to mark parts can only be done during the photochemical machining process. It is not a marking method for existing parts. Those are usually marked via laser or mechanical engraving.

Photochemical Etching Builds Uniquely Valuable Parts

Aerospace Parts

Photochemical machining is used to build precision components for aerospace and defense applications, including fine mesh screens for aircraft engines and fuel systems, flat spring electrical contacts and sensor components.

Medical Applications

The medical industry requires precision parts for many applications. Photochemical machining is used to make stents and filter meshes, micro-scalpels and sensor components.

Automotive Components

Photochemical machining is used to make small, complex parts for today’s vehicles, including battery terminals, speaker grills, washers and EMI shielding.

Designing for Photochemical Machining

Engineers need to consider several important rules when designing parts for photo chemical etching. This helpful guide summarizes the best practices you need to keep in mind.

Additional Resources – Photochemical Etching

Why Choose Fathom for Photochemical Etching?

-

Fathom has the expertise to meet your requirements for flat, burr-free parts.

-

We’ve been marking parts using photo chemical etching for over 50 years.

-

Our experts have over 30 years of experience helping customers optimize their part designs and material selections for this unique manufacturing process.