Injection Molding

-

Optimize Your Part & Tool Designs for Manufacturability

-

Tool Production & Injection Molding Under One Roof

-

Simplify Your Supply Chain with Flexible Sourcing

Trusted by Industry Leaders

How Plastic Injection Molding Works

Advantages & Disadvantages of Injection Molding

Advantages

-

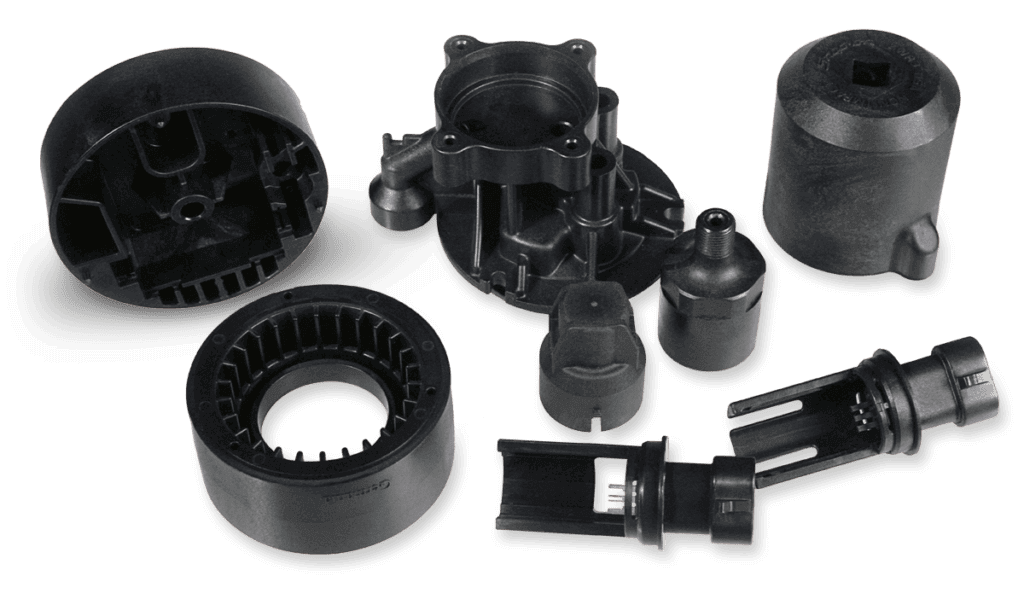

High-Volume Production

Injection molding is extremely efficient for producing large quantities of identical parts, with cycle times that can be as short as a few seconds.

-

Low Cost Per Part

For large production runs, the cost per unit is very low, making it ideal for mass manufacturing.

-

Low Labor Costs

Injection molding is highly automated, requiring only one operator to manage multiple machines, which significantly reduces labor costs.

-

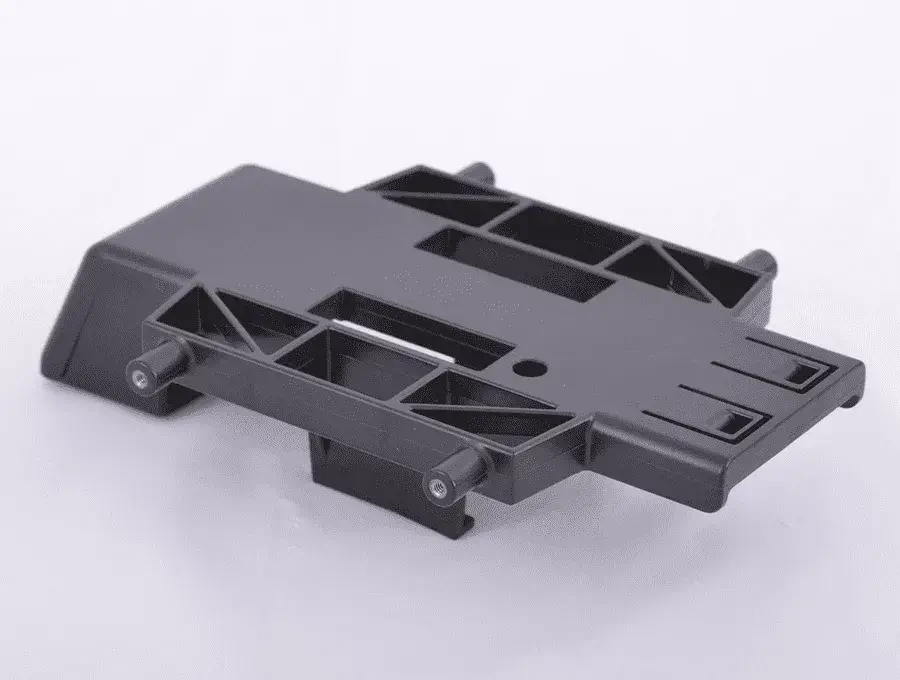

Design Flexibility

Injection molding enables you to create complex and intricate designs with fine details.

-

Precision & Consistency

Injection molding produces parts with tight tolerances and a high degree of consistency from one part to the next.

Disadvantages

-

High Tooling Costs

The cost of creating the custom mold can be very high, sometimes reaching tens or hundreds of thousands of dollars, making it impractical for small production runs.

-

Long Lead Times

The design and manufacturing of the mold can take weeks or even months. Once production starts, the cycle time for each part can be lengthy, depending on its size, thickness, and complexity.

-

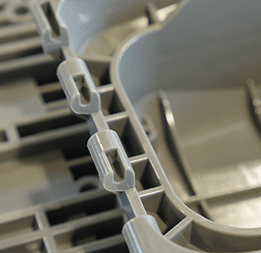

Design Limitations

Parts must be designed with the molding process in mind. Features like undercuts and sharp corners can be difficult or expensive to produce, and uniform wall thickness is generally required.

-

Part Size Limitations

While there is no theoretical limit to the size, very large parts require enormous, expensive machines and molds, and can be prone to issues like warpage and uneven cooling.

Engineer Better Parts for Injection Molding

Learn best practices for wall thickness, draft, gating, and material selection to reduce risk and improve manufacturability. A must-have guide for creating parts that scale cleanly from prototype to production.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.