Tight-Tolerance CNC Machining for High-Performance Applications

Our Customers

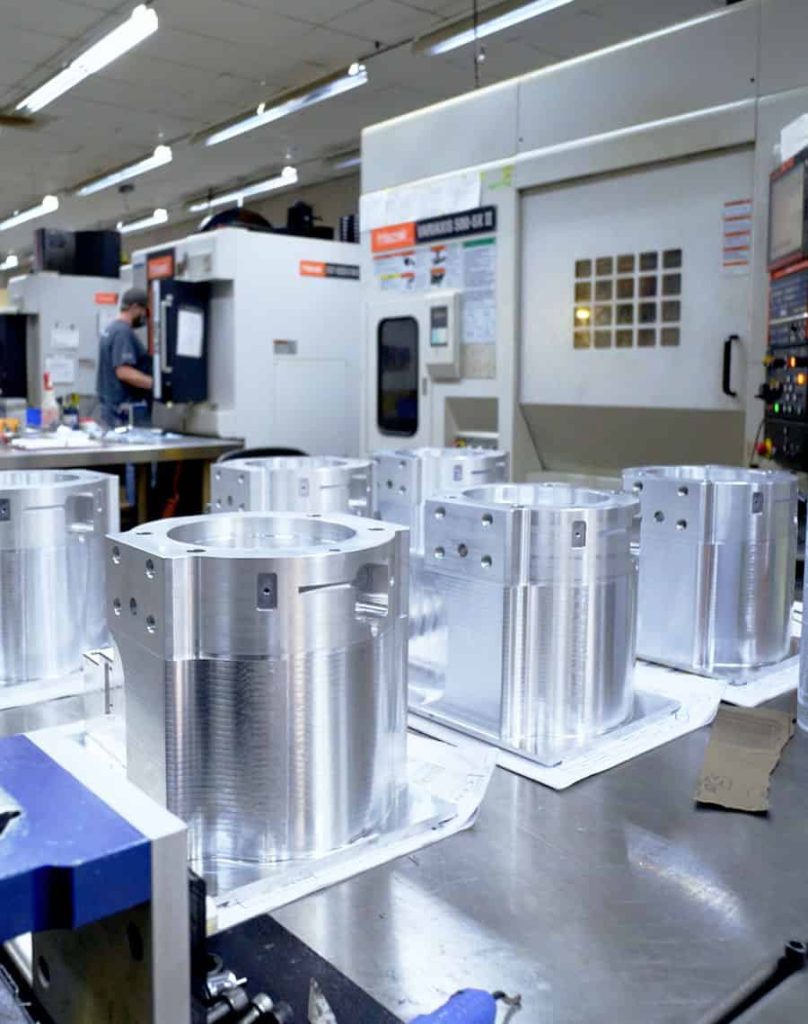

Precision CNC Machining for Demanding Applications

During the last 40+ years, Centex Machining by Fathom has built a reputation for precision CNC machining with leading companies in the medical device and semiconductor manufacturing industries.

These customers hold their manufacturing partners to exceptionally high standards. We’re a high-performance, responsive, quality-focused contract manufacturer that can meet or exceed your expectations, too.

Our facility in Round Rock, Texas offers completely integrated manufacturing services for metal CNC machining projects, including:

-

Cutting-edge manufacturing technology

-

Precise production control

-

Strict quality control standards

-

Advanced engineering expertise

-

Streamlined quoting and project management

Services & Capabilities for Custom CNC Machining

As a leader in medical device manufacturing, Centex Machining by Fathom has built some of the most complex assembled products in the business – experience that sets us apart from the competition.

CNC Machining

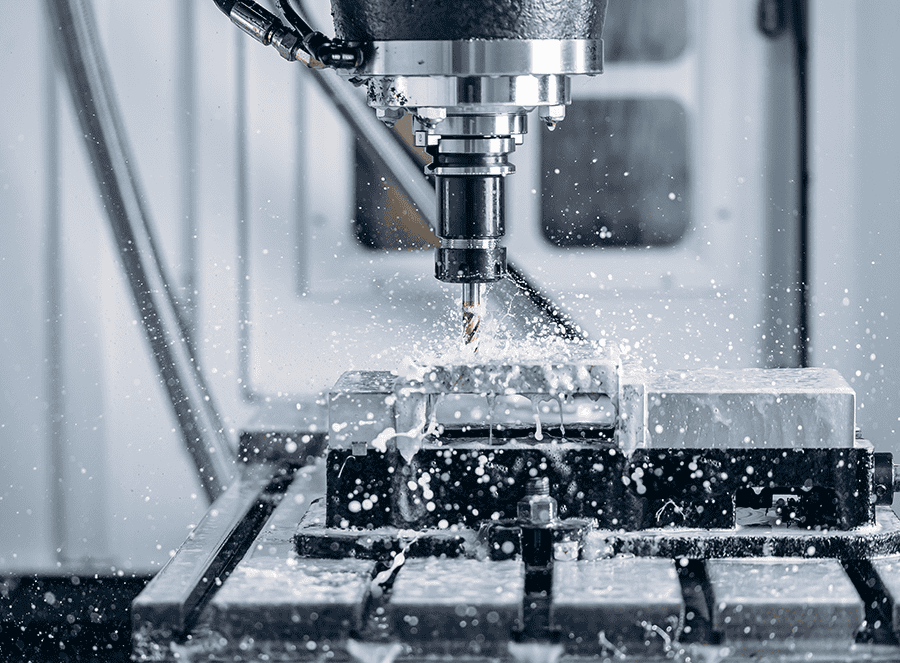

CNC Milling & Turning // We use 3-, 4- & 5-Axis CNC milling and turning machines to tackle our customers’ most sophisticated machining needs. Five-axis milling machines enable the cutting tool to approach the workpiece from all directions. This enables them to cut more complex, precise shapes without having multiple handling operations.

Wire EDM Machining // Wire EDM and sinker EDM ensure that we can create your complex geometries with exceptional accuracy.

Welding and Finishing

Laser Etching & Precision Welding // Our TIG welding processes are compliant with AWS standards and are free of all surface and subsurface defects. Building parts with defect-free surfaces is critically important in the medical device manufacturing industry. Any parts that will be used in the human body must be built to the highest standards.

Post Processing

Heat Treating // Heat treatment removes stresses that may build up in the material during processing. It can also be used to enhance the hardness of metals. Chart recordings and hardness testing are archived as required by our customers.

Passivation // Passivation is a chemical treatment for stainless steel and other alloys that enhances the ability of their surfaces to resist corrosion. Centex Machining by Fathom has extensive nitric and citric passivation experience.

Metal Finishing // Vibratory finishing using belting, polishing, grit blasting and shot peening to provide the correct finish.

Chemical/Electrical Finishes // We are experts in cosmetic anodize, hard chrome, electro-polishing and other chemical or electrical finishes. We can easily comply with all surface texturing and finish requirements.

CMM Inspection Services // Including control plans, validations, data collection and analysis per ISO13485 and ISO9001.

Laser Marking // Laser marking ensures traceability, compliance with regulations and enhances patient safety. We can create very fine, detailed markings, essential for identifying small medical instruments and implants.

Customer Testimonials

Precision CNC Machining for Discerning Customers

40+

75+

ISO 9001

ISO 13485

Industries served

Centex Machining by Fathom has cultivated a reputation for excellence in multiple industries:

-

Medical

-

Semiconductor

Applications

We fabricate a wide variety of products for our discerning customers, including:

Medical

- Implants: Knee, hip, shoulder, toe, ankle, femoral, tibial and trial implants

- Surgical instruments: Drill guides, reamers, inserters, extractors, retractors, slap hammers, saw guides and broaches

- Cutting tools

Semiconductor Components

- Machined components for atomic layer deposition (ALD)

- Chemical vapor deposition (CVD)

- Physical vapor deposition (PVD)

- Lithography machines

See What Centex by Fathom Can Build For You

Download our linecard for a clear, premium overview of our precision CNC capabilities and the engineering expertise that sets our team apart.

A Passion For Precision Since 1992

Laser Manufacturing started as a family business back in 1992 serving the semiconductor industry in central Texas. In 2019, we acquired Centex Machining, which added implants into our portfolio of products along with the required medical certifications (ISO13485) and FDA approvals for tooling and implants. In 2022, Centex Machining was acquired by Fathom.

Doing business today as Centex Machining by Fathom, we provide everything from quick turn prototyping to product development and contract manufacturing for the medical and semiconductor industries.

We’re hyper-focused on what our customers need. Our core value is passion for precision. It drives everything we do, every day.

Service Area

While we partner with companies nationwide, our Round Rock location also proudly supports many customers throughout the region, including:

Austin | College Station | San Antonio | Houston | Killeen | Temple | Waco | San Marcos | Dallas | Pflugerville | New Braunfels | Fort Worth | Arlington

Why our customers choose Centex Machining by Fathom

-

We’re Committed To Prototyping

Many larger machine shops prefer to focus on big production jobs. They aren’t usually interested in prototyping projects. At Centex Machining by Fathom, it’s one of our specialties. We can help you iterate your design from concept to production, quickly and efficiently.

-

Advanced Engineering And Production Expertise

All project quotes are reviewed by our engineering, operations, quality and production control teams. They will recommend design changes to improve the manufacturability of your parts. They may also make recommendations on materials and processes based on the geometry of your parts and the applications in which they will be used.

-

Certifications and Compliance

Because Centex Manufacturing by Fathom is a key player in medical device contract manufacturing, you benefit from our stringent processes and quality standards. We adhere to ISO9001:2015 and ISO13485:2016 quality standards as well as FDA regulations, including cGMP. Maintaining these quality certifications signifies Centex by Fathom’s investment in both equipment and professional personnel. It also reassures customers that the processes are proven and repeatable, inspections are precise, and all parts meet your requirements, every time.

-

A Long Track Record Of Success

Majestic Metals was founded in 1979. During the last 40-plus years, we’ve built an exceptional reputation for service, quality and speed.