Fathom’s Low-Volume Production Services

Fathom is hiring for multiple positions across our nationwide sites! To see all open positions, click here

From prototyping to production, Fathom delivers precision manufacturing at scale. Explore our comprehensive suite of U.S.-based services—from CNC machining and molding to advanced metrology and outsourced solutions—trusted by leaders in aerospace, medical, robotics, and beyond. Every project is backed by expert support, strict certifications, and scalable technology.

Fathom provides full-spectrum manufacturing solutions tailored to your product journey—from early-stage concept to scalable production. Our services are built to accelerate timelines, reduce costs, and ensure quality across every phase.

Helping you solve your biggest manufacturing challenges – with White Glove Service

Leverage our deep engineering expertise and white-glove support from prototype to production to bring your new products to market faster.

Tariffs. Instability. Margin Pressure. Fathom Edgeworks was built to outsmart the chaos and outprice the competition.

We specialize in high-stakes sectors where precision, speed, and reliability matter most. Explore how Fathom supports innovation across regulated and fast-moving industries.

High-precision where performance and compliance matter most.

Quality controls for regulated environments.

For tight tolerances, reliability, and scale.

The consistency and control for advanced fabrication.

Precision for reliability, repeatability, and production readiness.

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

All other industries beyond our five primary markets.

Stay ahead with expert content, guides, and case studies that support smarter decisions and better manufacturing outcomes.

Fathom customers love our hands-on approach to engineering and production. Read the stories.

Check out our industry events, facility tours, and expert-led manufacturing experiences.

Tour our facilities, get an inside look at state-of-the-art manufacturing technologies and more.

A place for expert insights, industry trends, and practical manufacturing tips from the Fathom team.

Find quick answers to common questions about our capabilities, processes, and getting started with Fathom.

Learn more about Fathom’s mission, people, and footprint across the U.S. We’re committed to excellence, innovation, and supporting our customers at every stage of the product journey.

Fathom is a U.S.-based advanced manufacturer built to serve engineers with speed, scale, and precision.

Stories, announcements, and milestones shaping Fathom’s role in modern manufacturing.

25+ processes, real production capacity, and a white-glove experience—Fathom delivers more than just parts.

Low-volume production is a manufacturing method for creating small to medium quantities of parts, ranging from dozens to several thousand units. It prioritizes flexibility, customization, and rapid response over the cost-per-unit efficiency of mass production.

Many third-party manufacturers prefer to avoid low-volume production in favor of long production runs of relatively simple geometries, but Fathom’s overall focus is supporting customers from early prototyping and bridge production to short-medium volume production.

Low-volume, high-mix projects are our sweet spot. We’ve been doing them for decades and we’re experts at them. Take advantage of our short lead times and flexible approach!

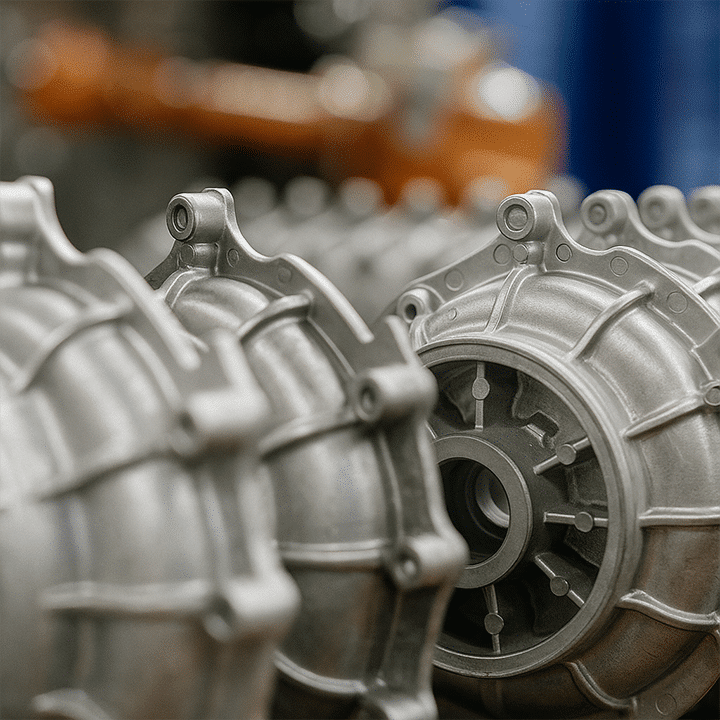

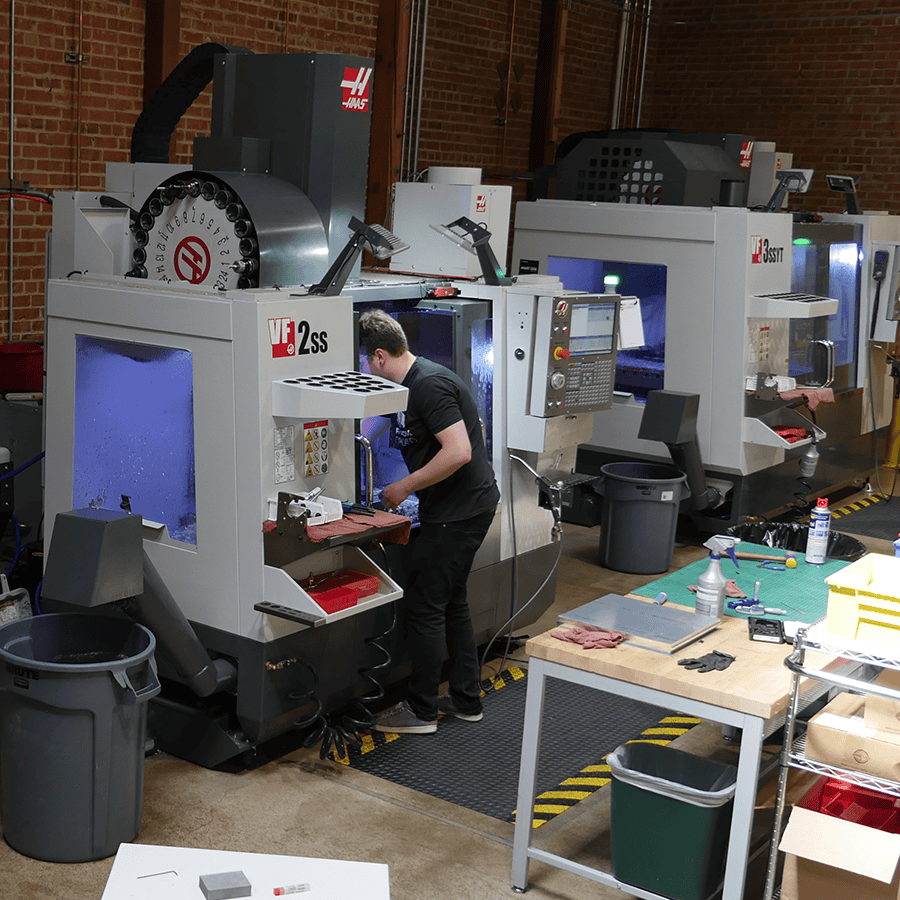

Fathom offers several technologies that are capable of small-batch production with customization including:

CNC machining makes it easy to move from prototyping into production. You can transition from CAD file to production in as little as a few days. It requires minimal investment to set up tooling and prepare the machine. It can accommodate design changes easily compared to other technologies.

Additive manufacturing is valued for low-volume production because parts can be produced in small quantities fairly quickly. Design changes are very easy to accommodate. Additive parts can often serve as production substitutes while injection mold tooling is being built.

If you’ve invested in tooling that’s designed to support a larger number of shots, you can easily scale up production quickly. It can do so while maintaining excellent repeatability. A variety of plastic materials, many with unique properties, are available for injection molding.

STEP can produce parts with injection molding-like quality but without tooling. It’s ideal for prototyping but is also designed to easily scale up to low-volume production because its build plate can quickly produce dozens of parts at time.

Moving your part from prototyping into production can be risky. Low-volume production enables you to take “baby steps” before committing to thousands or tens of thousands of parts.

Products can be pushed to market in a matter of days or weeks instead of months. Some industries change at a rapid pace and low-volume production can help you stay ahead of changing trends.

Gather customer feedback before doing high-volume production. Provide marketing teams with samples. Ideal for testing form, fit and function.

Digital manufacturing works directly from a CAD file. The file is used to build the item. There is no need for tooling or expensive and time-consuming machine setup.

High-volume production requires specialized tooling. Additive manufacturing or 3D printing significantly reduces lead time by eliminating the need for a mold or tooling.

Low-volume production usually means reduced costs and shorter production times, often with the ability to quickly make design changes.