Automotive & EV Manufacturing

Our Automotive & EV Customers

Automotive schedules don’t wait for sourcing to catch up

In the automotive and EV industry, production timelines move forward whether sourcing is ready or not. Designs evolve late. Volumes change. And supplier limitations quickly become program risks.

- Many vendors struggle to keep up.

- Communication is slow and impersonal.

- Engineering support is hard to reach.

- Issues in the supply chain often surface when there’s no time left to react.

What the automotive industry has been trained to accept in supply chain vendors is not what Fathom customers get. Fathom works alongside automotive teams when timelines tighten and flexibility matters most. We stay accessible, move quickly, and scale with your needs so sourcing delays don’t become production delays.

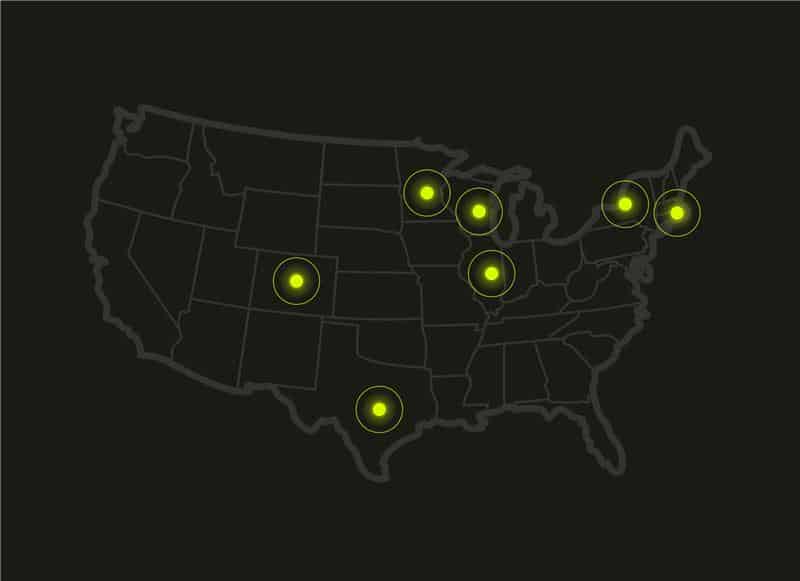

Fathom also builds close to where parts are assembled, and with seven U.S. locations, chances are we’re already operating near your assembly team. Close enough that when something shifts, we’re not waiting on freight or time zones. We’re talking directly, moving quickly, and keeping parts flowing.

In some cases, we’re close enough you could almost high-five someone on the line.

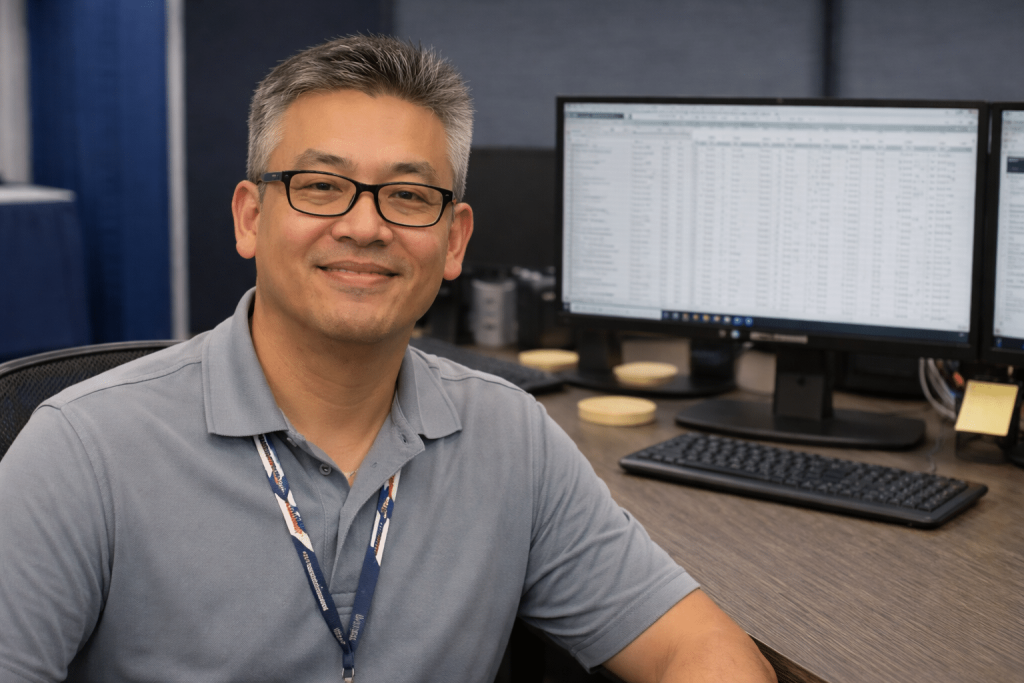

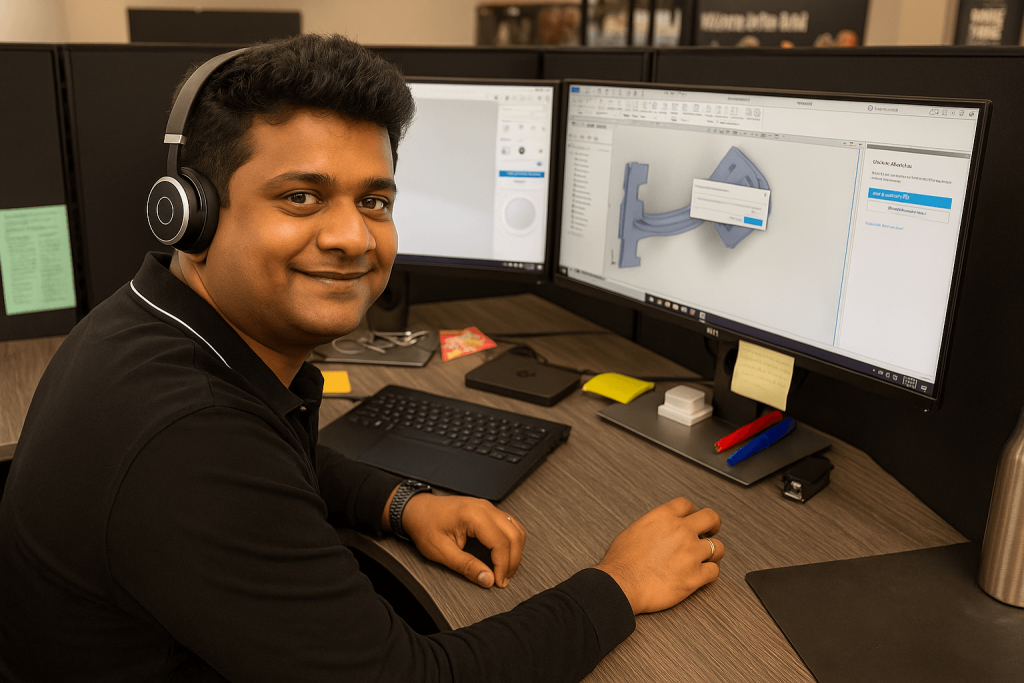

Human-First Manufacturing

From the moment you kick off your project, you’ll have access to a team of experienced professionals who will help you through every step of the process, from part design and prototyping to accelerating production. It’s all part of our white glove approach to meeting your needs.

Account Manager

Applications Engineer

Project Coordinator

Customer Success Representative

Our Expertise – By the Numbers

4,200+

10

25+

ISO9001

How Do Automotive & EV Manufacturers Use Fathom?

Unmatched Breadth of Technologies

We offer more advanced manufacturing technologies than any other contract manufacturer. That enables automotive and EV OEMs to get more of their needs met with one supplier.

Rapid Prototyping

We’re optimized to manage the rapid prototyping needs of our customers. Our expert engineers will help you quickly test, iterate and finalize your part designs for production.

Product Lifecycle Support

We’ll support your needs throughout the product development lifecycle – from early prototypes for design validation and late-stage prototypes as well as bridge production and full production. We specialize in low-volume/high-mix projects – ideal for new platform launches.

Engineering & Design Support

We take a hands-on, white glove approach to DFMs. That helps ensure that all of your potential part design issues are identified and solved early in the process. We’ll help you optimize your part designs, production processes and material selections for the best results, at the best price.

Quality Assurance

At Fathom, our commitment to in-house inspections enables us to turn around parts quickly, including CMM validation, surface inspections and tensile strength testing. In addition, we have a proven ability to comply with our customers’ specific process, material and workmanship standards.

Comprehensive Capabilities for the Automotive & EV Industries

With a portfolio of 25+ advanced manufacturing technologies, we’re able to provide you with blended solutions that meet your exact requirements. It’s all backed by our white-glove, hands-on service. From traditional vehicles to next-generation EVs, from bumper to bumper, we’ve got you covered.

Unmatched Additive Expertise

As automakers seek ways to enhance tomorrow’s vehicle designs while reducing costs, 3D printing is a key technology. We have over four decades of expertise in additive manufacturing. We also offer in-house post-processing of 3D-printed parts under one roof, which can save you time and money.

Complex Metal Forming

Our sheet metal experts can help you optimize your designs for production, from large exterior panels to precision forming of small, complex parts like brackets, connectors and contacts. We also offer a full range of finishing options for your formed metal parts.

Injection Molding

For consumer-facing components, nothing beats the surface quality of injection molded parts. We have decades of expertise designing and building mold tools for automotive components including insert molding and overmolding.

Combating Pricing Pressure

As an automotive OEM, you’re under constant pressure to contain costs. Fathom offers a broad portfolio of domestic, hybrid and overseas sourcing solutions to match any budget and grow with your needs. We manage the process from end to end, from prototyping to production, so you don’t have to.

Common Automotive & EV Applications

We have years of experience delivering high-quality exterior, under-hood and interior parts for numerous types of vehicles.

-

Exterior trim body parts and panels

-

Undercar aero shields and panels

-

Fluid tanks and plastic housings

-

Underhood components

-

Wiring harnesses

-

Interior trim

-

Mounts and brackets for in-dash navigation and entertainment systems

-

Manufacturing tooling and fixtures

Why Choose Fathom for Your Automotive and EV Projects?

By partnering with Fathom, you can concentrate on vehicle design and final assembly while offloading complex manufacturing work to a trusted, specialized partner.

-

Unmatched In-House Capabilities

Fathom offers one of the world’s broadest platforms of traditional and advanced digital manufacturing technologies, all in-house, including additive manufacturing, CNC machining, injection molding and sheet metal fabrication. This integrated approach enables you to use a single, turnkey supplier for diverse part needs, simplifying your supply chain management.

-

EV-Specific Engineering Expertise

Fathom has a proven track record of working with major EV manufacturers and offers unmatched engineering expertise tailored to the electric vehicle industry’s specific needs. We understand the unique requirements for components like battery pack parts, under-hood elements and interior/exterior trim.

-

Accelerated Product Development

Fathom is uniquely organized to support a flexible development environment, ideal for the rapid iteration needed in the hyper-competitive EV market. Our focus on prototyping, low-to-mid-volume production and a “value engineering” approach helps us refine designs and bring products to market faster.

-

Scalability and Flexibility

OEMs can leverage our scalable capacity to adjust production volumes seamlessly, avoiding significant capital investment in your own facilities. This flexibility is beneficial for both early-stage startups and established manufacturers transitioning to EV production.

-

Quality and Certifications

Fathom is committed to high quality, proven with certifications like ISO 9001, ensuring that all parts meet stringent specifications and industry standards. Our focus on manufacturing excellence often results in consistency equal to or better than in-house production.

-

Customized Solutions

Fathom provides customized programs to our automotive and EV customers. We work closely with them to optimize part designs, select appropriate materials and ensure the most cost-effective and efficient production solutions.