Why Contract Manufacturing Must Balance AI-Generated Quotes with Human Engineering Expertise

The promise and reality of AI in complex quoting processes

The contract manufacturing industry stands at a critical inflection point: embrace AI-powered automation or risk obsolescence.

But as leaders rush toward digital transformation, many are discovering that technology alone cannot deliver the outcomes they seek. Truly effective solutions must balance AI-driven quoting systems with irreplaceable human expertise.

Manufacturing has entered what the World Economic Forum calls the “Fourth Industrial Revolution,” where AI and automation are reshaping every aspect of production. According to McKinsey’s State of AI report, 63% of manufacturing organizations have implemented AI in at least one business function, with quoting and procurement among the fastest-growing applications.

The appeal is undeniable: AI in manufacturing promises to transform the labor-intensive quoting process into something faster, more accurate and more scalable. Early adopters report impressive metrics:

- 40-60% reduction in quote turnaround time

- 15-25% improvement in quote accuracy

- 30% increase in quote volume capacity without additional staffing

These statistics paint an attractive picture. But dig deeper into implementation experiences, and a more complex narrative emerges.

The initial rush to AI-powered quoting tools created an industry-wide overemphasis on speed at the expense of accuracy and relationship management. Many manufacturers discovered that while algorithms excel at processing standard configurations, they falter when handling the complex, customized requirements that define today’s manufacturing landscape.

The Limitations of Algorithm-Only Approaches

The current generation of AI quoting tools has transformed the industry landscape, but not without significant limitations:

Technical Constraints

AI in manufacturing excels at pattern recognition but it struggles with the unexpected. Manufacturing quoting, with its endless variables and custom specifications, frequently ventures beyond the parameters of training data. When faced with novel scenarios, many AI systems tend to:

- Generate misleading quotes with hidden errors

- Reject potentially valuable business opportunities as “unquotable”

- Produce quotes with extremely wide pricing bands to accommodate uncertainty

The Missing Human Element

Beyond technical limitations lies a more fundamental issue: The relational aspect of manufacturing partnerships.

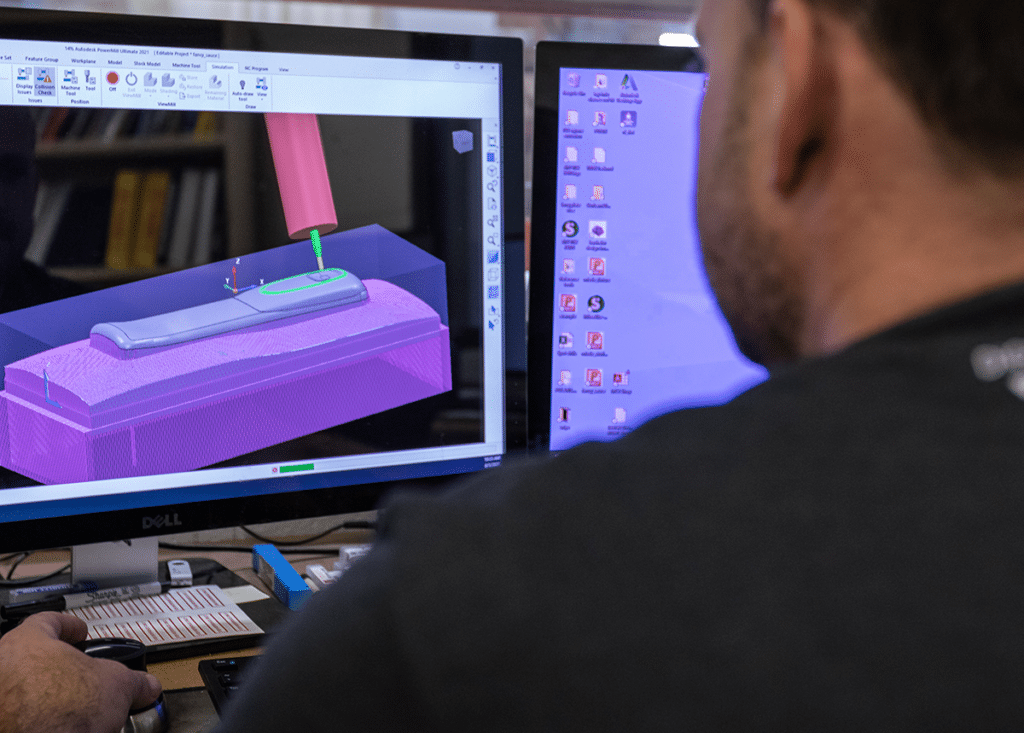

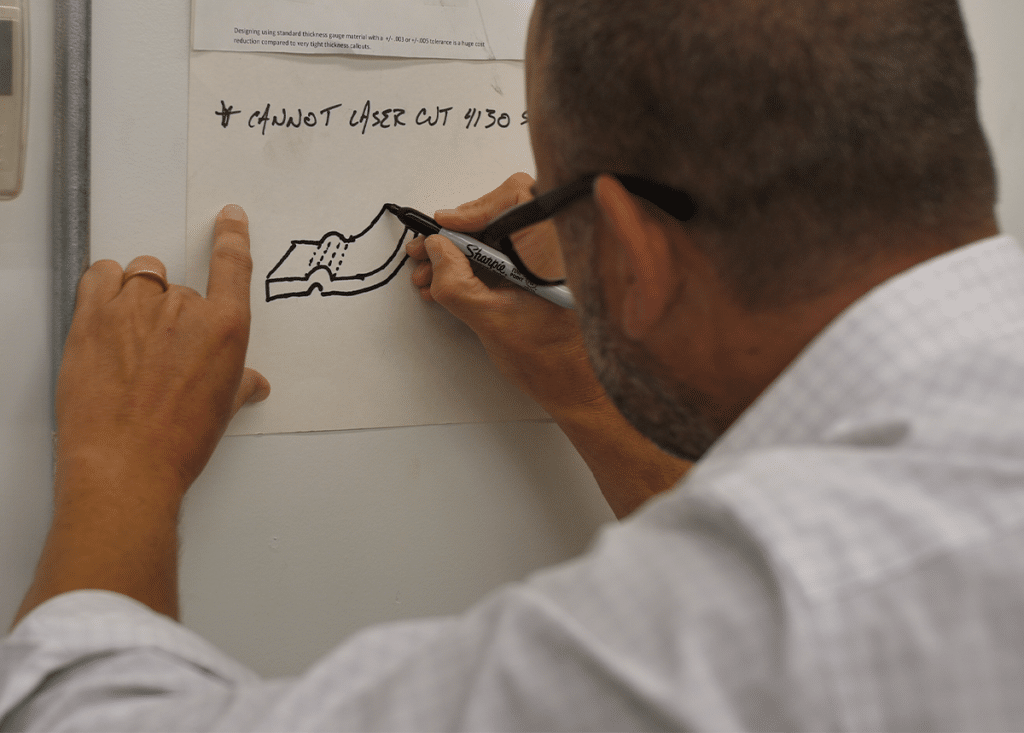

Manufacturing isn’t just about producing parts; it’s about solving problems collaboratively, especially during the product design and prototyping process. The most successful manufacturers don’t just fulfill orders. They participate in their customers’ innovation process. That requires human judgment, creativity and relationship building that algorithms simply can’t replicate.

There are multiple variables in every part build. Changes to any one of them may have an impact on the part’s manufacturability and cost. Experienced engineers can help you make the intelligent trade-offs that may be required to meet your part performance requirements at a cost-effective price.

The Emergence of Human-AI Collaboration Models

Forward-thinking manufacturers are pioneering a new path that combines AI efficiency with human expertise.

The manufacturers seeing the greatest success are those who view AI in manufacturing not as a replacement for human expertise but as an enhancement. The algorithms can handle data processing and basic pattern recognition while human experts can focus on relationship management, complex problem-solving and opportunity development.

Reimagining the Manufacturing Partnership

This human-AI collaboration model represents more than a technological approach. It reflects a fundamental rethinking of the manufacturer-customer relationship.

Rather than positioning manufacturers as interchangeable vendors differentiated only by price and delivery speed, it elevates them to strategic partners in their customers’ success. In particular, the right advice can help the customer bring their new product to market faster and save them money, too.

“The future of work is a partnership between humans and AI, where each enhances the other’s strengths. AI in manufacturing excels at processing data and handling repetitive tasks, while humans bring critical thinking, emotional intelligence and creativity. Together, they create a powerful synergy that combines efficiency with thoughtful decision making,” explains Sadagopan S., Executive Vice President, Global Head of SaaS & Commercial Applications, Digital Business Services, HCLTech.

The companies embracing this philosophy are transforming their quoting process from a transactional hurdle into a value-adding consultation. They’re using AI in manufacturing to process routine aspects while focusing human expertise on:

- Understanding the strategic context and design intent behind the customer’s new parts

- Identifying optimization opportunities that are often invisible in specifications

- Suggesting alternative approaches that might better serve customer objectives

- Building relationships that transcend individual transactions

The Path Forward: Balancing Technology and Humanity

As manufacturing confronts unprecedented change, the winning strategy appears increasingly clear: leverage technology for what it does best while preserving the human elements that technology cannot replicate.

In this balanced approach lies not just operational efficiency but strategic differentiation: The ability to transcend the constraints of commoditization and establish manufacturing relationships built on partnership rather than mere transaction.

As the contract manufacturing industry evolves, the most successful manufacturers won’t be those with the fastest algorithms, but those who do the best job of combining technological power with human wisdom. This is especially critical during the early stages of the product lifecycle, when smart part design, material and process decisions can make a big impact on the success of the overall project.

Even as our industry shifts toward automated quoting systems, Fathom remains committed to partnering with you to deliver the quality and expertise you expect. From prototypes to mid-volume production, we tailor our services to meet your needs.

We don’t just process orders, we listen to you and deliver the solutions you need. We’re not only committed to producing parts that meet your requirements but also to providing you with service and support that exceeds your expectations.

Are you ready to experience the Fathom “white glove” difference?

Let’s talk about your next project!

References

The State of AI in 2023: Generative AI’s Breakout Year; McKinsey, April 1, 2024

Balancing AI And Human Expertise: The Key To Impactful Digital Transformation by Sadagopan S,; Forbes, Sept. 12, 2024.