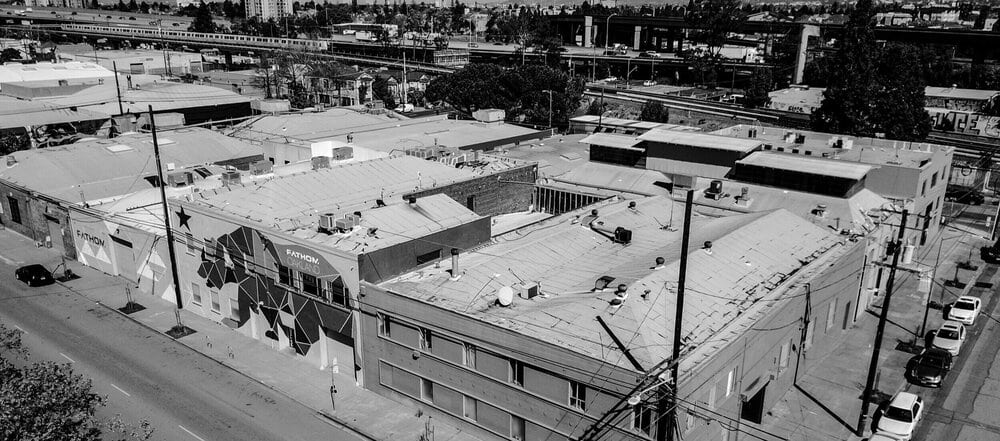

Three companies, FATHOM, Midwest Composite Technologies (MCT) and ICOMold have combined to form the largest privately held digital manufacturing service provider in North America. The combined company now has a multi-faceted go-to-market strategy, leading digital tools, a nationwide presence and industry-leading manufacturing capacity and capabilities to serve our customer’s prototyping and production needs.

The acquisition allows Fathom to scale in significant ways that will drive meaningful results for new and existing customers— further enhancing our facilities and expanding capabilities to meet a growing market demand for speed and design freedom.

— Rich Stump / / CEO, Fathom

List of comprehensive capabilities include:

- 200,000+ Square Feet of Manufacturing Space

- 35+ Years of Manufacturing & Engineering Expertise

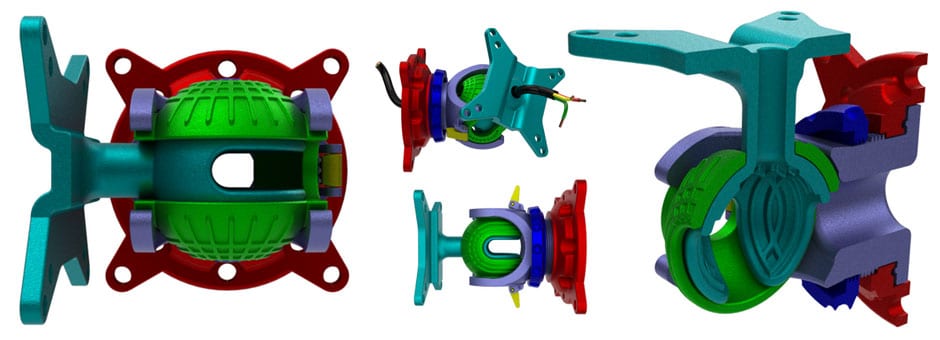

- 14 manufacturing production methods

- 6 additive manufacturing technologies

- Over 90 industrial grade / large format additive systems

- A combination of over 125 mills, lathes, presses & 3D printers

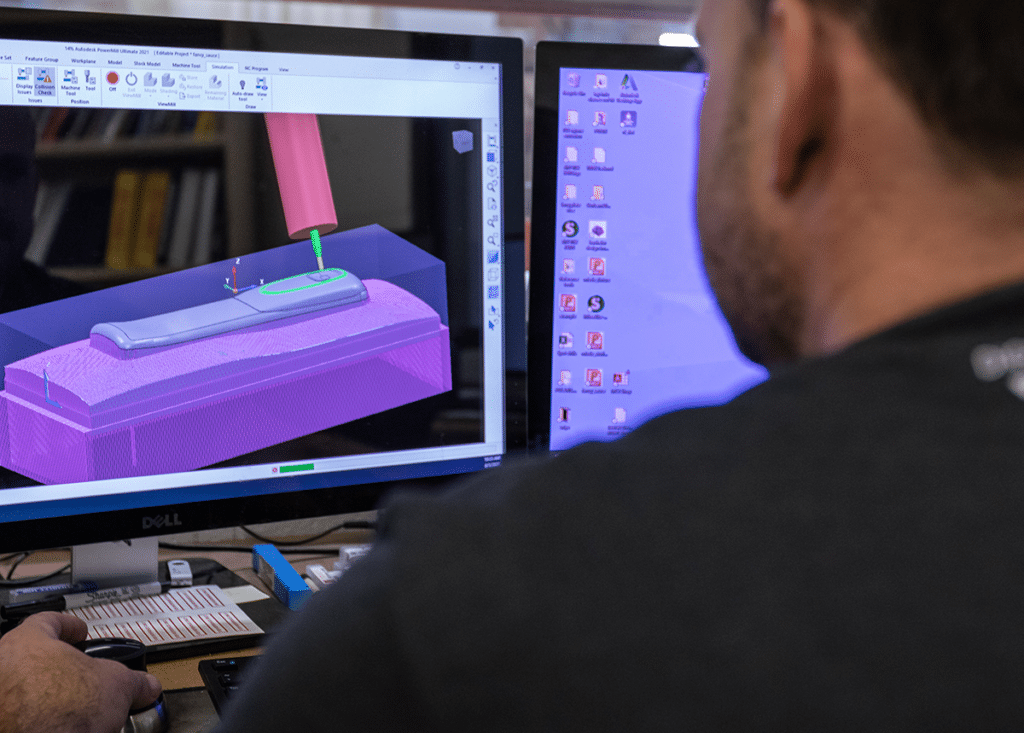

- Domestic CNC

- Urethane casting

- Domestic and International Injection Molding

- Enhanced model finishing and assembly

Every day, companies from all industries trust us with low- to high-volume projects because of our award-winning expertise, speed and commitment to quality. From aesthetic models to functional prototypes to end-use parts on factory floors and store shelves, our experienced team can help you identify what technology and material make the most sense for your application type.