Student Donates to UC Berkeley

UC Berkeley Student and Make The Unmakeable Challenge Champion Donates Grand Prize 3D Printer to Student Club

Casey Rogers, Champion of the 2015 Make The Unmakeable Challenge, donated his grand prize 3D printer to the student-run 3D Modelling Club at UC Berkeleys Bechtel Engineering Center. Rogers, a founding member of the club, was eager for the group to start using a professional-grade system.

“The uPrint SE is a really incredible 3D printer and I’ll have to make sure to make the best possible use out of it, said Rogers. I cant wait to see what kind of cool stuff my fellow club members can come up with.”

Fathom delivered his prize on campus and helped the club install the uPrint SE, getting students up and running in a matter of minutes. Check out pictures, quotes and select Casey Rogers interview excerpts from the grand prize presentation below! Read the story on 3Dprint.com and 3Ders.org.

The UC Berkeley Makerspace

The UC Berkeley makerspace is relatively new, only formally established at the start of the Fall 2015 semester. Were currently seeking funding from the university to renovate the space with a desktop CNC mill, new furniture and a lot of other exciting things! Also our club members have the opportunity to network in Silicon Valley and the whole Bay Area.

Our makerspace is kind of an interesting and unique group. Were about half Computer Science majors, half miscellaneous humanities majors—weve given a lot of people, including myself, a glimpse into this really exciting new technology that our curriculum and careers otherwise wouldnt have provided.

The Winning Design

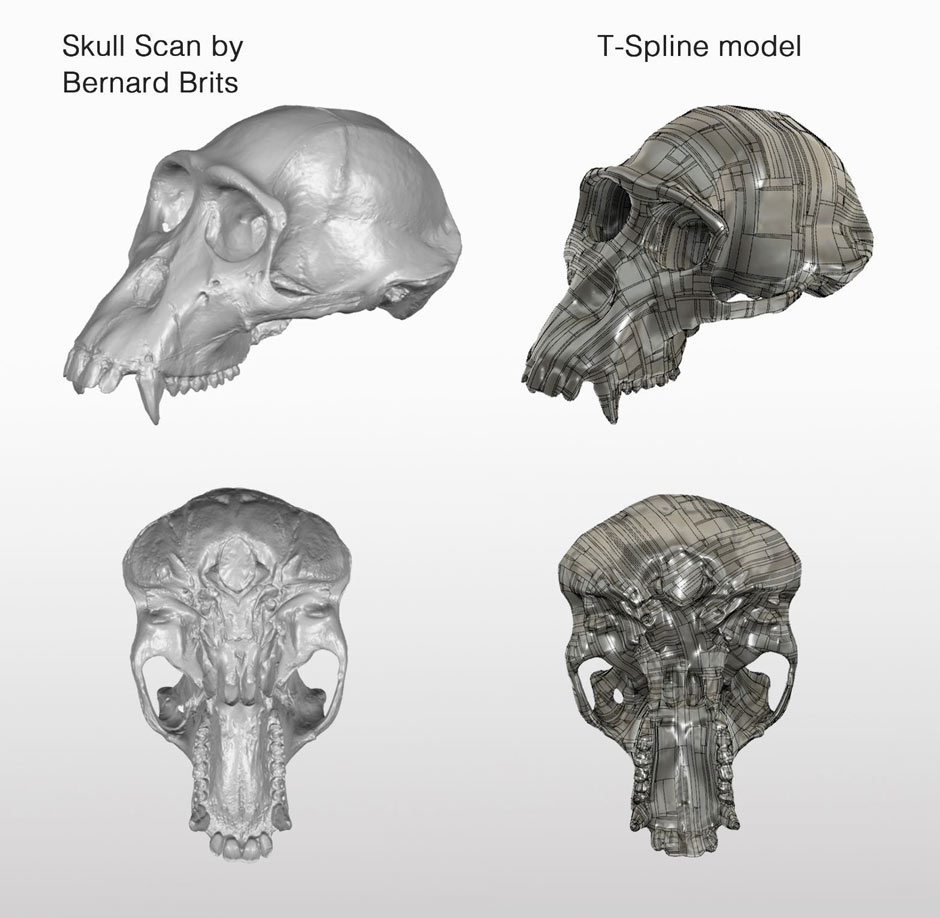

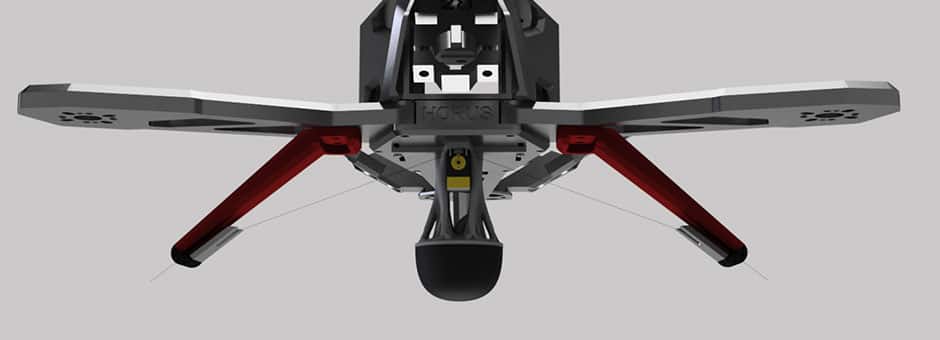

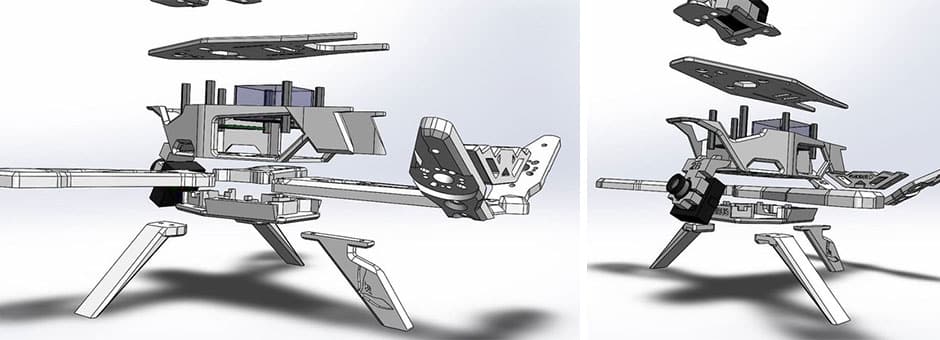

For this project I really tried to focus on creating something that leveraged the strengths of 3D printing, as opposed to just being printable. The organic branching structure and complex geometry of the arm reduces weight while maintaining strength but cannot be manufactured using traditional methods because of its intricate shape. I also used living hinges in the landing gear by leveraging 3D printing’s ability to print in multiple materials.

I first started working with additive technologies my freshman year at UC Berkeley via a 3D printing club on campus called 3DMC. Since then I’ve worked on countless projects. This past summer I had an internship with a 3D printing startup working with direct metal printers. I’ve done a lot of work designing 3D printing projects in Fusion, including designing the quadcopter universal gripper arm. Fusion’s robust support for imported meshes, relative to other CAD packages, was key in incorporating the gripper arm’s organic structure into my design.

Read the Q&A with Casey Rogers when Fathom announced him as the winner of the third and final round of Make the Unmakeable Challenge.

The Grand Prize

The uPrint SE is an industry favorite among designers, engineers and educator. As the UC Berkeley makerspaces most robust system, the 3D printer SE will enable their undergrad team to create much more advanced high-quality prototypes and parts.

- Build Size 203 x 152 x 152 mm (8 x 6 x 6 in)

- Layer Thickness 0.254 mm (0.010 in)

- Model Material ABSplus

Check out all of the Make The Unmakeable Challenge Finalists submissions—

- Round 1: Creative Solutions to New Year’s Resolutions

- Round 2: Innovative Design for Jigs and Fixtures

- Round 3: Horus Drone Accessories

To learn more about the services used in the production of these winning submissions, go to the Fathom services page.