New Paradigm for Women’s Health

Oakland Startup Uses 3D Printing to Develop Product that Ends Uncertainty in Women’s Health Diagnoses

A customer of Fathom, NextGen Jane, has set its sights on a nearly universal healthcare issue: How can we stop health problems before they occur? How can we be more proactive in anticipating health needs?

Founders of NextGen Jane, Ridhi Tariyal and Stephen Gire, have seen first-hand the terrifying consequences of delayed response to infectious diseases, having both studied the transmission of disease while working in West Africa. With deep backgrounds in the science of public health, the co-founders identified a fundamental problem with medical check-ups for women around the globe—they are too infrequent, too costly and too inconvenient to adequately monitor health.

“NGJ’s main goal is to provide women with agency. Agency is the ability to act and make decisions autonomously. In order to do this, we are empowering women with actionable health data so that they can make decisions about their health, family planning and their personal life.”

Fathom sat down with Ridhi and Stephen to discuss their young company, their ultimate goals and women’s health. In this exclusive interview, learn more about NextGen Jane and its founders, as well as insight on the accelerated product development process by Fathom.

A common critique of many healthcare systems is that they are fundamentally reactive in nature—the opportunity to be more proactive with health is something we can all support. How does NGJ play a part in that paradigm shift? How do people stand to benefit from using your product?

NGJ’s product can serve as a sentinel system that surveys the body every month and can catch certain conditions that may have no symptoms. One of the more devastating examples is ovarian cancer which is often caught in stage 3 or stage 4, leading to poor survival rates. The reason ovarian cancer is detected so late is that there are few noticeable systems that alert doctors of the disease at an early stage. Even late stage signs can be non-specific. However, having access to cells from the ovaries on a regular basis could change how the disease is detected and could allow doctors to intervene before overt symptoms present themselves. A key innovation in the NGJ system then becomes the potential to address conditions before they become intractable or have long-term consequences such as infertility.

Tells us more about the NGJ product and the process by which it was developed? How did 3D printing change your design?

The NGJ product is a device that can easily process biomaterial collected from a woman’s body with a tampon and allow it to be analyzed. The ‘blood’ on a tampon is actually a rich biological matrix that can be very informative of women’s reproductive health. This biological material can be tested on a variety of different scientific platforms in order to tell you essential information about your genetics and how your environment may be affecting your health, as well as bio-indicators about reproductive health.

The NGJ team has minimal design experience, but we are scrappy and we were able to create a prototype from our initial concept. But we needed guidance from professional engineers and designers to get our product where we wanted it.

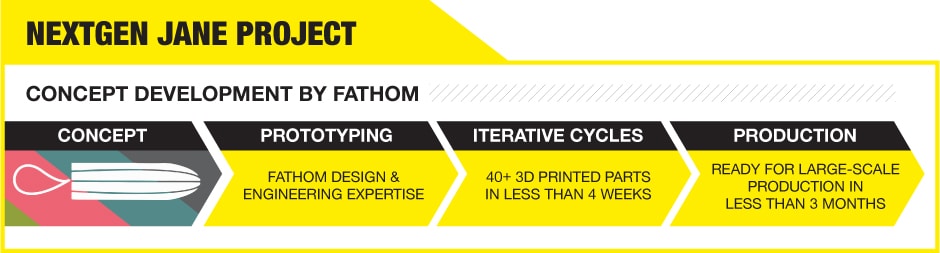

Fathom’s expertise allowed NGJ to quickly improve upon the design of our device, which included engineering for fluid dynamics, manufacturing and integration into existing medical infrastructures. We used Fathom’s 3D printing services to quickly iterate on the design and functionality. Once the design was finalized, we worked with Fathom who developed injection mold tools for large-scale production of our device for clinical trials (see below, click on image for larger view).

Based on your work so far, it seems that part of your motivation is to shift the national and global dialogue surrounding women’s health. How have you integrated design and strategic communications in shaping the conversation around your product and movement?

As a ‘smart tampon’ company empowering women to take control of their reproductive health, we are generating conversation about many traditionally taboo topics. In the last few years, we are thankful for the many efforts to de-stigmatize menstruation—It’s ‘normal’ and a natural part of the female experience. But it’s still difficult to talk about sexually transmitted infections or infertility due to conditions like endometriosis.

So, a fundamental part of our job has been to create a positive and non-judgmental conversation around how a tampon can be useful in helping you manage your health and fertility. Our website, by design, encourages women to learn more about their reproductive health. The website synthesizes large amounts of information and makes it accessible to a curious consumer.

We want to avoid the cold and clinical feeling of many traditional medical environments—we are creating an experience where it feels good to learn more and everything from our color palette to our web design aesthetic reinforces that positivity.

We also host what we call “Boston Tea Parties,” which involve gathering women together and starting the conversation face to face. When women begin to share stories of their own health concerns, struggles and worries, it immediately de-stigmatizes the issues around reproductive health. There’s nothing quite so powerful as having scary thoughts about your health in your head and then hearing others articulate the same things. It begins to create this shared experience and empowers you to accept your concerns and then vocalize them with doctors, family and society. It gives women a voice.

What does success look like for the NextGen Jane team and how will you measure it?

A woman who is able to track her health by herself in a convenient and well-informed manner gains more control of her circumstances. Whether she is deliberating when to start a family or whether to freeze her eggs or is genetically predisposed to breast/ovarian cancer and wants to find ways to manage that risk much more closely, we want to give her the tools to do it.

Our barometer for success is a reduction in anxiety for women as they navigate the challenging task of balancing work, family planning, sickness and health without an increase in cost and time spent in labs.

An essential aspect of any medical product’s development is its endurance through extensive testing and clinical trials—where is NGJ in this process and what are the next steps?

NGJ is excited to announce that we have started our second clinical trial and are actively enrolling women into a study to understand what makes women healthy and what causes specific reproductive conditions. This trial is the first to integrate a smart tampon device with a next generation sequencing platform. This small pilot study will be used to generate data for a larger clinical trial to submit to the FDA for approval of our device.

In progressing to the next phase of trials, are more women from the Oakland area participating in events? How are people getting involved?

Yes, women all over the Bay Area are getting involved and participating in this phase of the trial. NGJ holds recruitment events throughout the city where we invite women to break bread with us and talk about women’s health and how our study is helping to shed light on specific reproductive conditions.

We’re encouraging women all over to take control of their own health! These events are a great way to get involved and contribute—Anyone interested in participating should visit our website, sign up for our newsletter to hear about upcoming events or reach out to learn more about the trial!