Thermoplastic Polyurethane Powder for Selective Laser Sintering

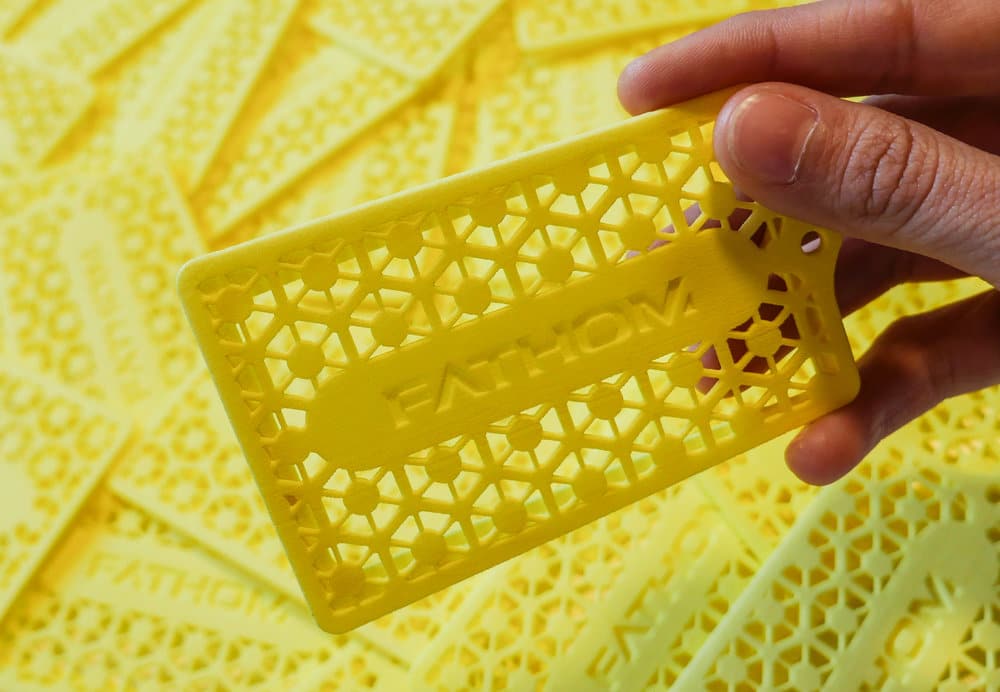

Fathom offers a new flexible material option for 3D Printing with Selective Laser Sintering.

Fathom has partnered with BASF to drive innovative product offerings and give our customers more material options. Selective Laser Sintering (SLS) with Thermoplastic Polyurethane (TPU) is now available with the flexible and durable Ultrasint® TPU 88A.

SLS TPU is yet another additive technology offered by Fathom. We have over 450,000 square feet of manufacturing space spread across the country giving customers access to an extensive slate of digital manufacturing technologies including PolyJet, Fused Deposition Modeling, and Multi Jet Fusion. TPU forming is also available with Urethane Casting.

Ultrasint® TPU 88A is a versatile, elastomeric material that offers great shock absorption and rebound. SLS TPU parts will have a rubber-like feel and a smooth white surface. TPU 88A is resistant to water with high UV stability making it a good material choice for items that may come into contact with the elements. This elastic material is used to make industrial tubes, pipes, consumer footwear, sports equipment, and automotive components. TPU SLS parts can be made for prototyping proposes or as a production material for end-use parts.

| Additive Manufacturing Services By Fathom // Featured SLS Material Option // TPU (Thermoplastic Polyurethane Powder) | ||||||

|---|---|---|---|---|---|---|

| Tensile Strength | Young’s Modulus | Elongation at Break | Shore Hardness | Rebound Resilience | Material Overview | Download Data Sheet |

| 8 MPa | 75 MPa | 270% | 88-90 | 63% | Download PDF | Download PDF |

What is SLS?

SLS is an additive technology used to build parts layer-by-layer. The process starts with a digital model of the part in a Computer Aided Design (CAD) file. The SLS machine uses the CAD file to direct a powerful laser into a powder bed over the build plate. The laser traces the shape of the object, melting or sintering the plastic powder together. The build plate is then lowered and covered with more plastic powder. The laser then fuses the new layer to the previous layer. This process is repeated until the part is complete. The part is then excavated from the powder bed. Excess powder is shaken from the part before it is sent for further cleaning and post processing if required. Leftover powder can be reclaimed and used for another project.

Fathom has a fleet of SLS machines, including several large-format printers capable of producing over-sized parts. Speak to our experts about your next project or get started with an online quote.

For our Complete SLS Materials Options // SLS

Companies trust the Fathom team with low- and high-volume projects because of our award-winning expertise, quality, and speed. Our accelerated manufacturing capabilities allow for next day turnaround on SLS TPU parts. Running our 3D printing machines 24/7 enables us to meet tight deadlines while maintaining precise specifications. PostPro® 3D machinery further expedites and scales our 3D production capacity. This patented technology achieves a surface quality for thermoplastic polymer 3D parts that rivals injection molding. Large batches of parts can be run simultaneously and do not require any additional steps after the 90 to 120 minute process time.

Application Example // Industrial Tubes and Pipes

- Water tight down to 0.6 mm wall thickness.

- High burst pressure (e.g. 7.4 bar at 3 mm wall thickness).

- Good resistance to water and various chemicals.

- Readily implemented material model allows for further part optimization via BASF Ultrasim® simulation and design services.

Fathom is fueled by cutting-edge technology, with the speed and agility to provide the most impactful, on-demand manufacturing in the industry. Speak with our experts to find out how we may be able to reduce cost and cut turnaround time.