Our Quality Process

Fathom is hiring for multiple positions across our nationwide sites! To see all open positions, click here

From prototyping to production, Fathom delivers precision manufacturing at scale. Explore our comprehensive suite of U.S.-based services—from CNC machining and molding to advanced metrology and outsourced solutions—trusted by leaders in aerospace, medical, robotics, and beyond. Every project is backed by expert support, strict certifications, and scalable technology.

Fathom provides full-spectrum manufacturing solutions tailored to your product journey—from early-stage concept to scalable production. Our services are built to accelerate timelines, reduce costs, and ensure quality across every phase.

Helping you solve your biggest manufacturing challenges – with White Glove Service

Leverage our deep engineering expertise and white-glove support from prototype to production to bring your new products to market faster.

Tariffs. Instability. Margin Pressure. Fathom Edgeworks was built to outsmart the chaos and outprice the competition.

We specialize in high-stakes sectors where precision, speed, and reliability matter most. Explore how Fathom supports innovation across regulated and fast-moving industries.

High-precision where performance and compliance matter most.

Quality controls for regulated environments.

For tight tolerances, reliability, and scale.

The consistency and control for advanced fabrication.

Precision for reliability, repeatability, and production readiness.

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

All other industries beyond our five primary markets.

Stay ahead with expert content, guides, and case studies that support smarter decisions and better manufacturing outcomes.

Fathom customers love our hands-on approach to engineering and production. Read the stories.

Check out our industry events, facility tours, and expert-led manufacturing experiences.

Tour our facilities, get an inside look at state-of-the-art manufacturing technologies and more.

A place for expert insights, industry trends, and practical manufacturing tips from the Fathom team.

Find quick answers to common questions about our capabilities, processes, and getting started with Fathom.

Learn more about Fathom’s mission, people, and footprint across the U.S. We’re committed to excellence, innovation, and supporting our customers at every stage of the product journey.

Fathom is a U.S.-based advanced manufacturer built to serve engineers with speed, scale, and precision.

Stories, announcements, and milestones shaping Fathom’s role in modern manufacturing.

25+ processes, real production capacity, and a white-glove experience—Fathom delivers more than just parts.

As an advanced technology-driven manufacturer, Fathom has an established quality policy. This policy aligns with The Fathom Promise. Fathom uniquely blends industrial 3D printing and additive technologies with traditional manufacturing driven by a differentiated customer experience focused on speed, urgency and agility.

Fathom’s quality policy sets a defined framework for overall quality objectives. These objectives outline our commitment to customer satisfaction through Fathom’s comprehensive capabilities, expertise and continuous improvement initiatives.

The experts at Fathom are committed to understanding and anticipating customer needs in order to meet project requirements and exceed expectations. Fathom is committed to fostering a culture focused on a technology-agnostic approach. Fathom engineers and designers have the flexibility to leverage a wide range of technologies, materials and processes to provide expert recommendations to suit project priorities.

A defined QMS is a critical component for manufacturing companies to ensure regulatory compliance, meet/exceed quality standards and deliver products efficiently. Cross-functional QMS standards establish process documentation procedures that are repeatable and trackable leading to greater production efficiencies.

Fathom has outlined several key quality objectives as summarized below. The complete policy is available upon request.

Every project quote is expertly reviewed to ensure the file is optimized for production. Fathom utilizes a variety of processing software such as GrabCAD and Materialise Magics. If you have questions on preferred file types, contact a Fathom expert today.

Fathom’s detailed process documentation procedures ensure precise material traceability. All parts ordered through Fathom are delivered to the exact requirements outlined in the project specifications.

Fathom’s QMS procedures follow strict adherence to industry certifications. View Fathom’s complete listing of certifications by location here.

Due to strict production procedures, Fathom can provide a high level of consistency, quality and production-level repeatability.

The experts at Fathom are constantly looking for process improvements in order to exceed customer expectations and drive production efficiencies. The quality team drives process improvements across the organization with an emphasis on Lean Manufacturing, Statistical Process Control and Six Sigma methodologies.

Precise, thorough documentation is critical to providing high-quality, compliant parts to our customers. There are three ways Fathom ensures all customer expectations are met or exceeded:

Quality Management System (QMS) // Fathom’s quality team manages a real-time QMS that contains defined Standard Operating Procedures (SOP) and detailed step-by-step Work Instructions for all production areas.

Certifications // Fathom’s certifications include ISO 9001:2015 Certified, AS9100 Rev. D Certified, ITAR Registered, NIST 800-171 Compliant and ISO 13485 Certified. *Fathom certifications vary by location; please visit Our Certifications page for more information.

Security // Fathom’s security protocols across all facilities and as part of our IT system are industry-leading. These security efforts are in line with compliance measures and completely protect the intellectual property of our customers.

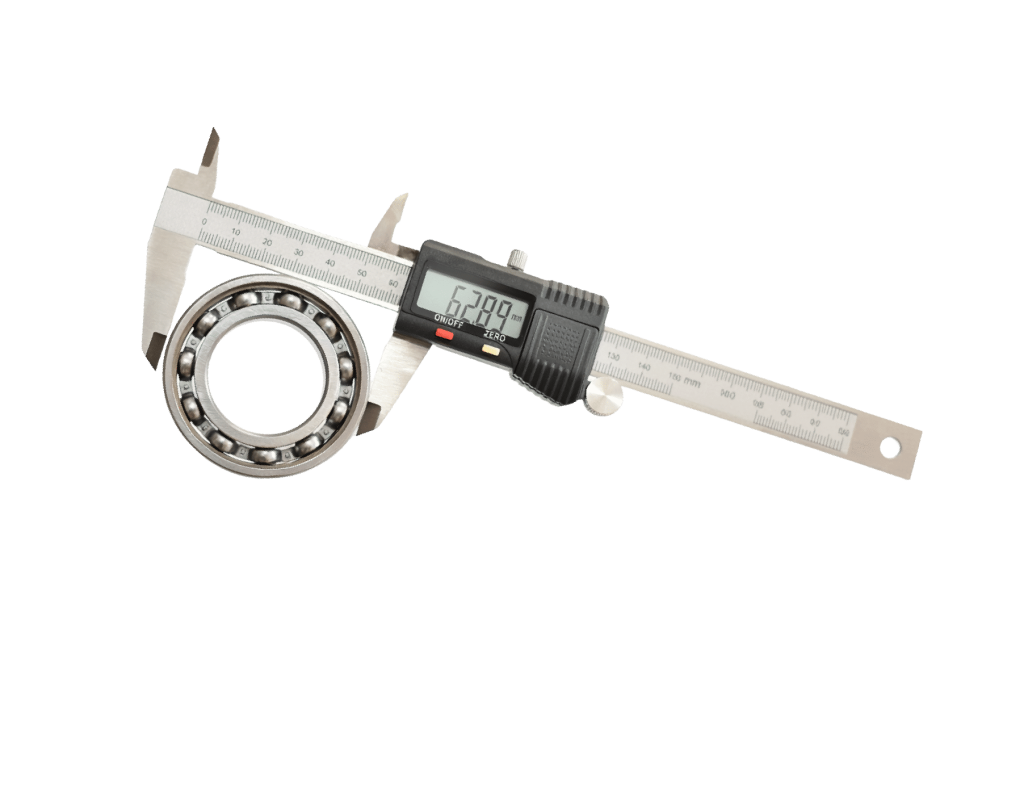

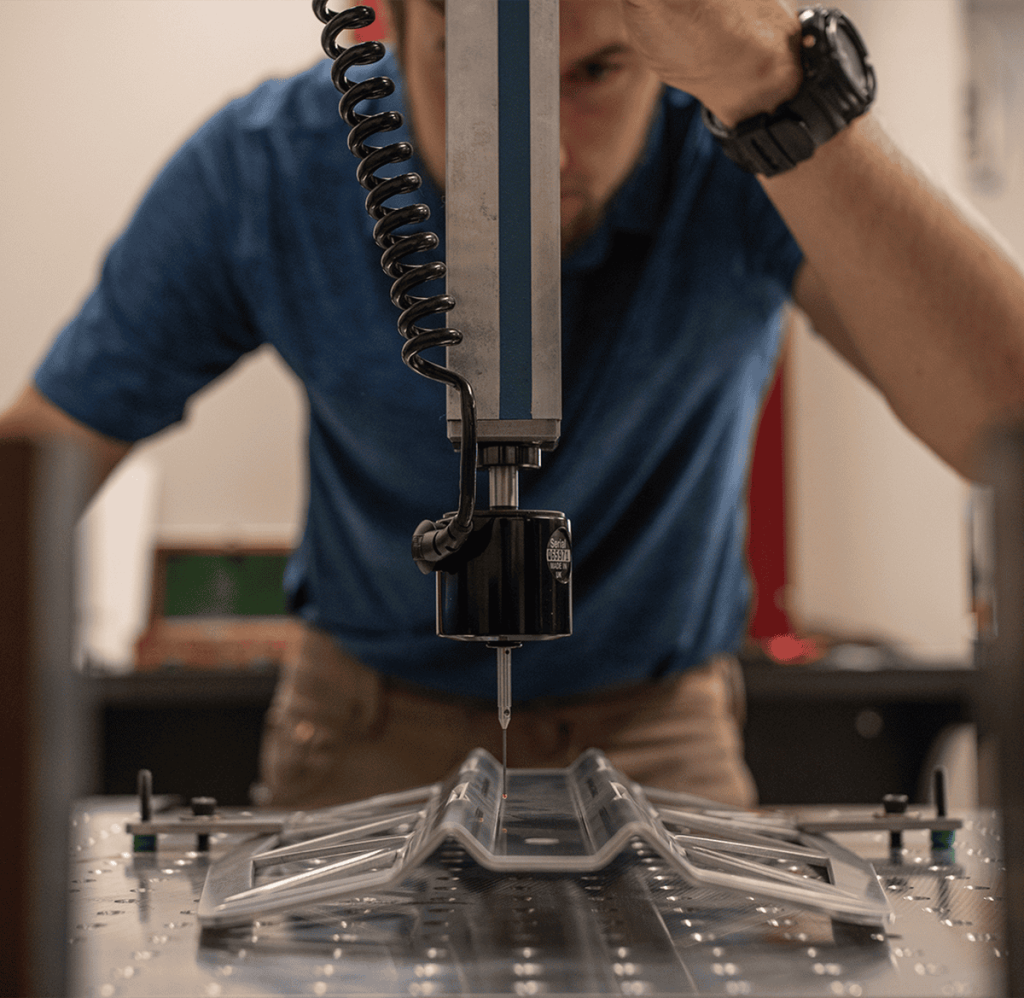

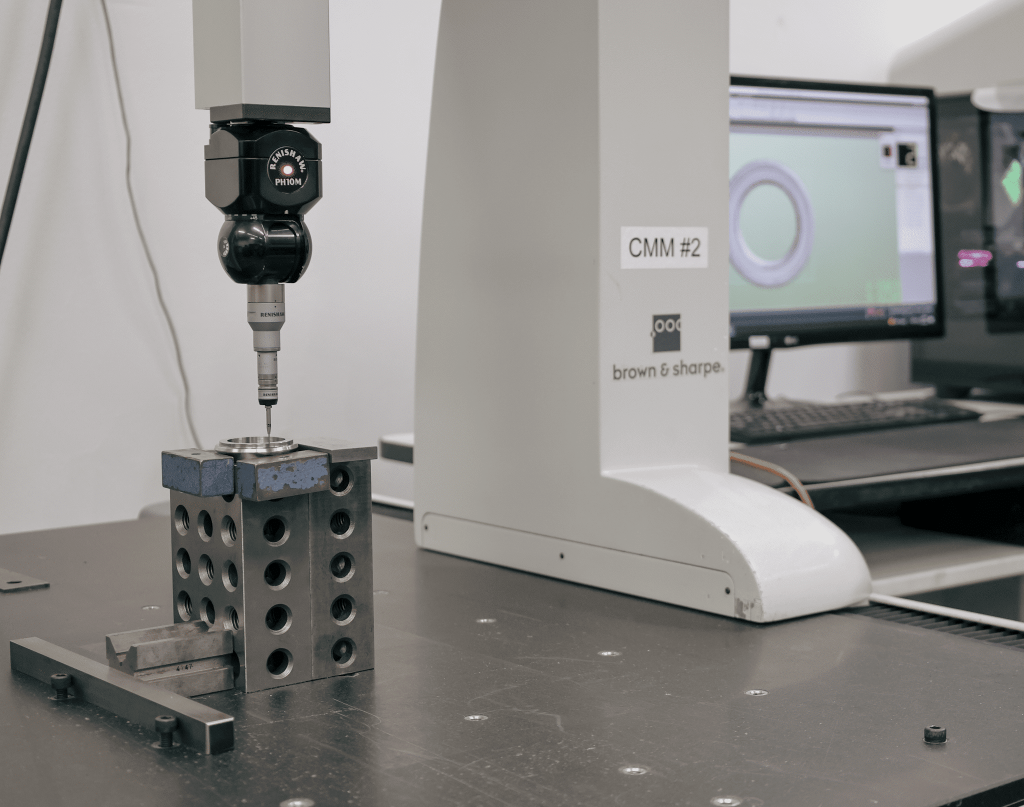

Fathom utilizes the most advanced, high-tech Coordinate-Measuring Machinery (CMM) to adhere to exact part specifications. In addition to large-scale measurement machinery, Fathom also utilizes the following measurement tools and testing procedures to ensure part consistency and accuracy:

Fathom has the expertise and technology to help you meet your needs faster

When working with Fathom, expect expert engineering recommendations and project management. The experts at Fathom are well-versed in Geometric Dimensioning & Tolerancing (GD&T), the language used by engineers to communicate measurement and tolerances via engineering drawings. The Fathom team is able to accurately confirm precise dimensional requirements through technical engineering expertise. Talk to us today to start your project!