Large Format Injection Molding

Are you facing tight production deadlines for large part injection molding? Do you need to validate designs quickly before committing to full production? Or perhaps you’re struggling with the complexities of sourcing large injection molded parts while maintaining quality and managing costs?

Fathom understands these challenges. We specialize in helping product development teams accelerate their timeline for large part injection molding without compromising on quality or breaking the budget.

Traditional approaches to large injection molding often force engineers into difficult trade-offs between speed, quality and cost. But with Fathom’s expertise and versatile manufacturing capabilities, you don’t have to choose. Our team provides guidance at every stage, from initial design through production, ensuring your parts meet specifications and timeline requirements.

What Qualifies as Large Part Injection Molding?

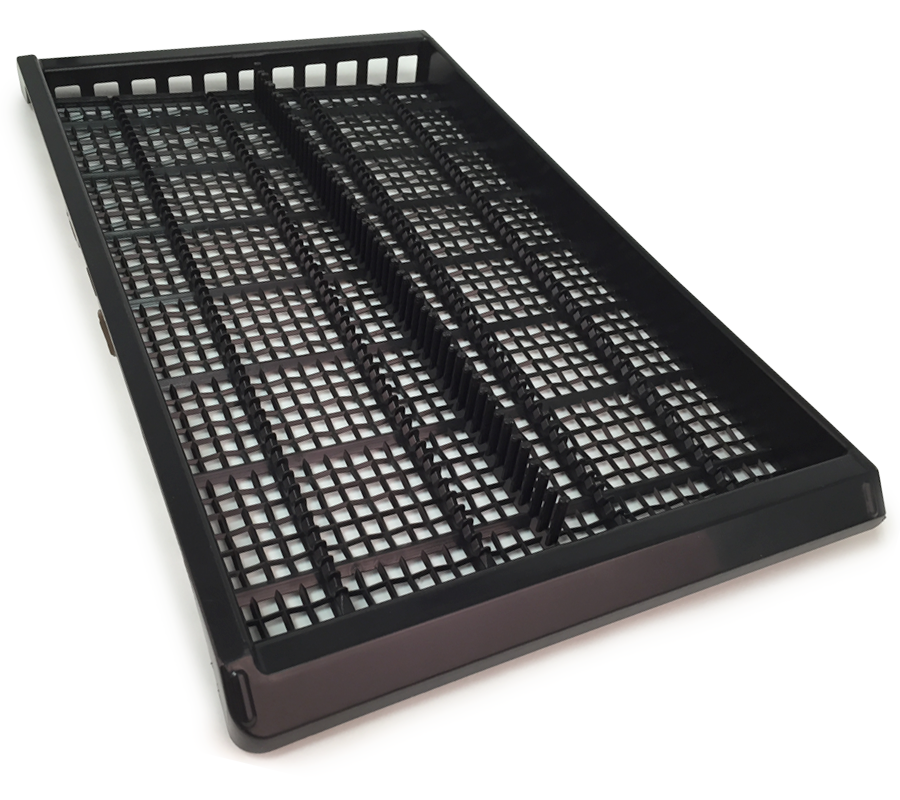

Large part injection molding is defined as components exceeding 24 inches in any dimension or weighing more than 10 pounds. These parts present unique manufacturing challenges and require specialized equipment and expertise. Some examples include

- Automotive dashboards and door panel components

- Industrial equipment housings and covers

- Medical device enclosures

- Agricultural equipment components

- Large consumer product housings

- Transportation interior components

Large injection molding requires specific considerations for design, material selection, tooling and equipment that differ from standard-sized parts.

Common Challenges with Large Injection Molding

Design Complexity // Large parts often have complex geometries, varying wall thicknesses and multiple features that can create manufacturing challenges. These complexities can lead to issues like warping, sink marks and inconsistent material flow.

Material Constraints // The size of large injection molded parts limits material options due to flow characteristics, cooling rates and structural integrity requirements. Material selection becomes critical to ensure part performance and manufacturability.

Tooling Considerations // Molds for large part injection molding require significant engineering expertise. They must accommodate proper gating, venting, cooling channels and ejection mechanisms to ensure consistent part quality.

Equipment Requirements // Large parts demand injection molding presses with high clamping forces (typically 500+ tons) and specialized material handling capabilities. Not all manufacturers have this capacity.

Quality Control // Maintaining dimensional stability and consistent quality across the entire surface of large injection molded parts requires specialized expertise and equipment.

Design Considerations for Large Injection Molding

When designing large plastic parts, consider these critical factors to ensure successful manufacturing:

Wall Thickness // Maintain uniform wall thickness wherever possible to prevent warpage, sink marks and internal stresses. For large parts, the recommended wall thickness typically ranges from 0.120″ to 0.250″ depending on the material and application.

Draft Angles // Incorporate adequate draft angles (typically 1-3° minimum, more for textured surfaces) to enable clean part ejection from the mold. Large part injection molding often requires larger draft angles than smaller components to prevent scuffing and other damage.

Ribs and Gussets // Strategically place ribs and gussets to enhance structural integrity while minimizing material usage. For large injection molded parts, ribbing becomes crucial for maintaining dimensional stability.

Gate Locations // Consider multiple gate locations to ensure proper material flow throughout the large mold cavity. This helps prevent flow lines, weld lines and inconsistent filling.

Cosmetic Considerations // Large visible surfaces may require special attention to maintain a consistent appearance. Our team can help you address cosmetic requirements through proper tool design and material selection.

How Can Fathom Help You

with Large Part Injection Molding?

We Have the Capacity // Through our international injection molding network, we have access to a wide range of injection molding presses, from 20 tons to 3,500 tons.

DFM Support Included With Each Quoted Project // Our experienced engineering team provides design for manufacturability (DFM) feedback at no additional cost. We can help you optimize your designs for large part injection molding while avoiding costly tooling modifications down the road.

Cost & Speed Advantages // Our international injection molding network can produce large parts at a fraction of the cost of U.S. manufacturers. This becomes an even bigger advantage when working with large part injection molding, which requires larger presses with huge clamping forces. Demand for high-tonnage injection molding presses in the U.S. is high, which means you may need to wait weeks or months to have your large parts produced. You can get them made faster using Fathom’s international injection molding network.

Applications for Large Part Injection Molding

Our expertise in producing big injection molded parts serves numerous industries, including:

- Automotive components and instrument panels

- Industrial equipment housings and covers

- Medical device enclosures and cases

- Agricultural equipment components and panels

- Consumer product housings and enclosures

- Transportation interior and exterior components

- Defense and aerospace applications

- Waste management containers and components

Industries We Serve

- Automotive and transportation

- Industrial equipment manufacturers

- Medical device companies

- Agricultural equipment

- Consumer products

- Defense contractors

- Energy and utilities

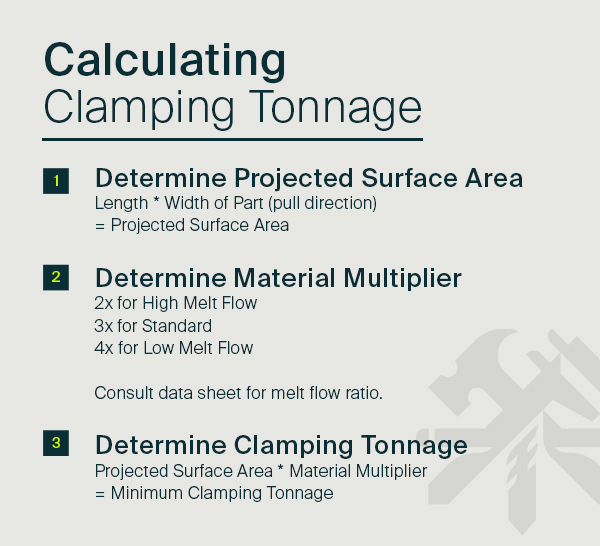

What Size Press Do You Need?

Use this convenient calculator to estimate the size of the injection molding press needed to produce your large parts.

Secondary Processes for Your Large Injection Molded Parts

Do your large injection molded parts require secondary processes? We can handle them for you and simplify your supply chain. Here are some of the processes we can do for you:

- Painting

- Pad printing

- Silk screen printing

- Powder coating

- Hot stamping

Why Choose Fathom for Your Large Plastic Part Projects?

Fathom’s robust international injection molding network has the equipment, capacity and expertise to produce your large parts quickly at the level of quality you expect.

Expert Guidance // Fathom’s team brings decades of injection molding experience to every project. We help you navigate material selection, design optimization and production planning for your large plastic parts.

Transparent Communication // From quoting to final delivery, your U.S.-based account manager provides clear, consistent communication throughout the entire process. You’ll also have access to an online discussion forum, where you can communicate with our overseas production team 24-7. Many of our customers consider this to be an invaluable tool because it helps keep tooling and molding projects flowing smoothly.

High-Capacity Presses // Our manufacturing network includes machines with clamping forces up to 3,500 tons, capable of molding large parts with precision and consistency.

Let’s get started on your large plastic part project today!