Summit by Fathom //

Transform Your Designs Into Production-Ready Parts

You face many challenges when moving parts from concept to prototyping and production for custom plastic injection molding. So many decisions. So many places where things can potentially go wrong. Delays. Cost overruns. Tooling issues. Part quality problems.

That’s why you need a custom plastic parts manufacturer that can do it all – from mold design and construction to prototyping and production. Summit by Fathom, a United States-based injection molding manufacturer, provides all these services under one roof, backed by decades of engineering and production expertise. We can help you bring your products to market efficiently and grow with your custom injection molding needs.

Our Comprehensive

Custom Injection Molding Services

Tool Building

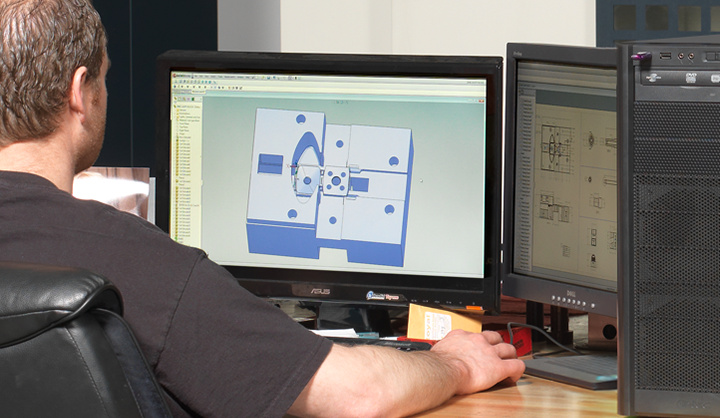

At Summit by Fathom, an injection molding company, we design and build multiple types of tools to meet all your custom injection molding needs. Our fully automated tool room enables us to cost-efficiently build your mold tools and get them into production faster. It also helps us keep our tooling costs as competitive as possible.

Advanced Tooling Solutions

At Summit by Fathom, you’ve got options to produce quality injection molded parts:

- Multi-Cavity // A tool that makes multiple parts in a single shot.

- Family Molds // This type of tool makes multiple related parts at the same time.

- Two-Shot Molding // Bi-injection rotary tools are designed to mold two materials together in a single cycle.

- MUD (Master Unit Die) Tools // A system where interchangeable tools are mounted in a modular frame. They can be swapped quickly to produce multiple variations of a part.

- Insert Molding // A metal part is placed in the mold cavity and plastic is molded around it. Threaded inserts are often used in parts that are part of an assembly.

- Overmolding // A part is molded using rigid plastic. A softer material is then molded on top of it. This technique is often used to provide a softer, more comfortable surface on tools.

Material Expertise

Our injection molding manufacturer engineers can provide you with guidance on material selection to ensure that your parts meet your performance requirements for:

- Mechanical properties

- Chemical resistance

- Temperature tolerance

- Regulatory compliance

Design for Manufacturability (DFM)

Summit by Fathom includes basic DFM feedback on new, quoted custom injection molding projects. Our engineers review your designs before tooling production, identifying potential issues related to:

- Wall thickness

- Draft angles

- Gate locations

- Parting lines

- Location of ejection pins

A more detailed DFM analysis is available upon request, for an added fee.

Fathom Manufacturing’s

Custom Injection Molding Process

1 // Design & Engineering Consultation

Our process begins with a thorough review of your project requirements. Our engineering team collaborates with you to optimize your design for injection molding, considering factors like:

- Part geometry

- Material selection

- Production volume

- Timeline requirements

- Budget constraints

2 // Tooling Development

Based on your production needs, we we build injection mold tooling that balances speed, cost and quality.

3 // First Article Production & Validation

After your tool is built but before it’s moved into full production, we produce first article samples for your approval:

- Dimensional inspection

- Material certification

- Functional testing

- Surface finish evaluation

4 // Production & Quality Assurance

Our ISO 9001:2015-certified manufacturing processes ensure consistent quality throughout your production run:

- Statistical process control

- In-line inspection

- Material traceability

- Comprehensive documentation

5 // Continuous Support

As your production needs evolve, our team provides ongoing support:

- Tool maintenance and modifications

- Production scaling options

- Secondary operations

- Assembly services

Choose Summit by Fathom for Your Custom Injection Molding Needs

At Summit by Fathom, we offer comprehensive custom plastic injection molding services that include tool design, building, qualification and production with a wealth of knowledge and expertise – all under one roof. One point of accountability enables us to streamline your project, solve problems faster and deliver high-quality parts. It also helps us keep our lead times to a minimum.

Let us help you tackle your next custom plastic injection molding project!