Modular Logistics Vehicle (MLV) with Additive Manufacturing

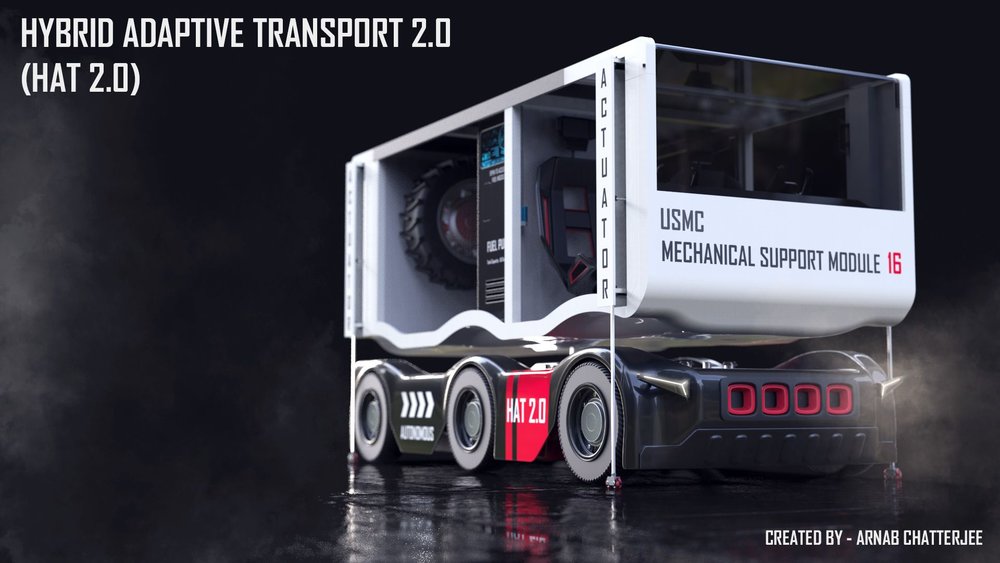

The Fathom team is excited to share a collaborative project for the United States Marine Corps (USMC), a modular vehicle system that meets a wide range of logistical missions. Together in partnership with Launch Forth, Deloitte and Siemens, Fathom took on the challenge of fabricating a crowd-sourced vehicle concept within an accelerated timeline.

The project started as an international challenge using the Launch Forth platform to prove the value of crowd-sourcing ideas instead of traditional product development practices. Many design entries were submitted and it was a tough decision for the judges, but ultimately the winning design best exemplified the innovative spirit of the Marines. The next step in the challenge was realizing the design as a fully functional prototype. This entire development process typically takes years and the USMC Co-Lab team wanted to find a better and faster, way to innovate.

3D CAD TO FUNCTIONAL PROTOTYPE IN 10 WEEKS

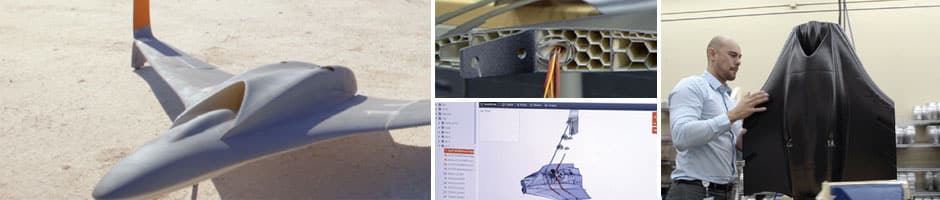

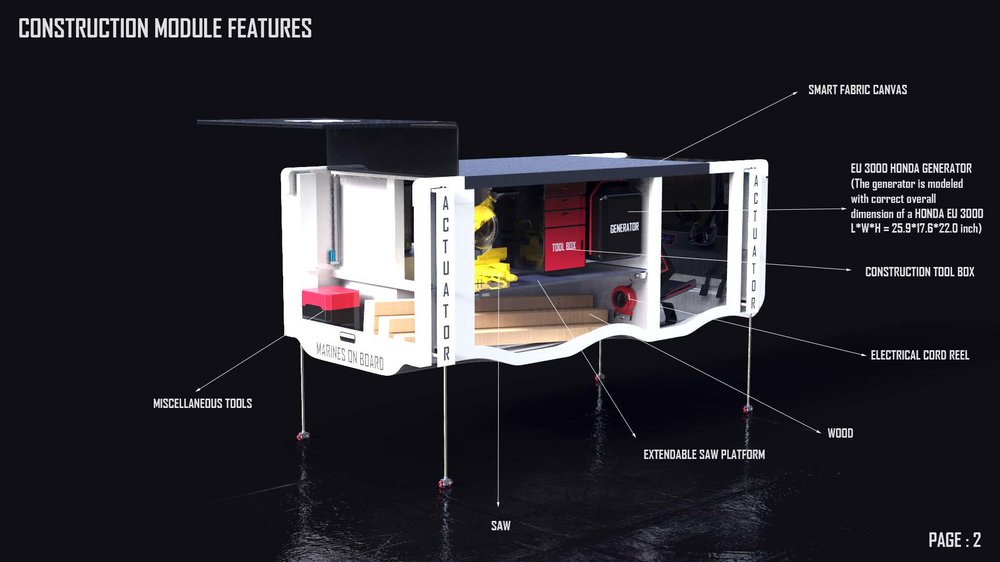

Fathom’s engineering and design team took over the winning concept, going from 3D CAD refinement to design for manufacturing to the fabrication of a working production-like prototype in 10 weeks. The team used both additive and traditional manufacturing processes to fabricate the modular vehicle, a hybrid approach that dramatically shortens product development and production timelines, while also enabling greater collaboration throughout.

- Vehicle Concept Included 1,800+ Components & Involved 2,000+ Project Hours Dedicated to Development/Fabrication/Logistics

- Design for Manufacturing (DFM) + Design for Additive Manufacturing (DFAM) Guidance

- 88 Additive Parts Manufactured in Engineering-Grade Materials (Multi Jet Fusion, Selective Laser Sintering, Fused Deposition Modeling)

- Accelerated Traditional Processes (CNC Machining, Plasma Cutting, Welding, Foam Cutting, Etc.)

Fathom’s digital manufacturing ecosystem of expertise and advanced technologies enables its customers to realize new or improved products in ways not previously possible. Watch the videos below to learn more about the inspiration behind MLV from the winning designer, as well as the steps Fathom took to make this design a reality for the Marines.

USMC CO-LAB, LAUNCH FORTH, DELOITTE, SIEMENS, & Fathom

In order to rapidly innovate for the Marines, USMC Co-Lab teamed up with Launch Forth to quickly leverage problem-solvers from around the world. It was important to the USMC Co-Lab that it demonstrate how today’s technologies, from crowd-sourcing to software to advanced manufacturing, can be leveraged to accelerate product development from years to months to weeks.

Launch Forth, in collaboration with Deloitte, Siemens and Fathom, challenged its global community using its online crowd-sourcing platform. From there, a digital thread (as referenced in the video below) was created to track the project from beginning to end. Built by Deloitte using Siemens’ PLM (Product Lifecycle Management) software, the project files from co-creation challenges were pulled into the secured cloud-based digital thread. From there, Fathom’s industrial designers and mechanical engineers accessed the 3D CAD files for further refinement and manufacturability before moving into production. After testing and validation, the functional prototype fabricated by Fathom was demonstrated at Camp Pendleton in San Diego, CA.

Check out the videos below for more information about MLV and the digital thread solution.

The Modular Logistics Vehicle (MLV) is one of the many automotive projects for the Fathom team—projects span many industry types such as medical, consumer products, electronics and aerospace. Fathom’s rapid prototyping and low- to high-volume production services include but are not limited to 3D printing, additive manufacturing, CNC machining, urethane casting, tooling, injection molding and industrial design/engineering support.