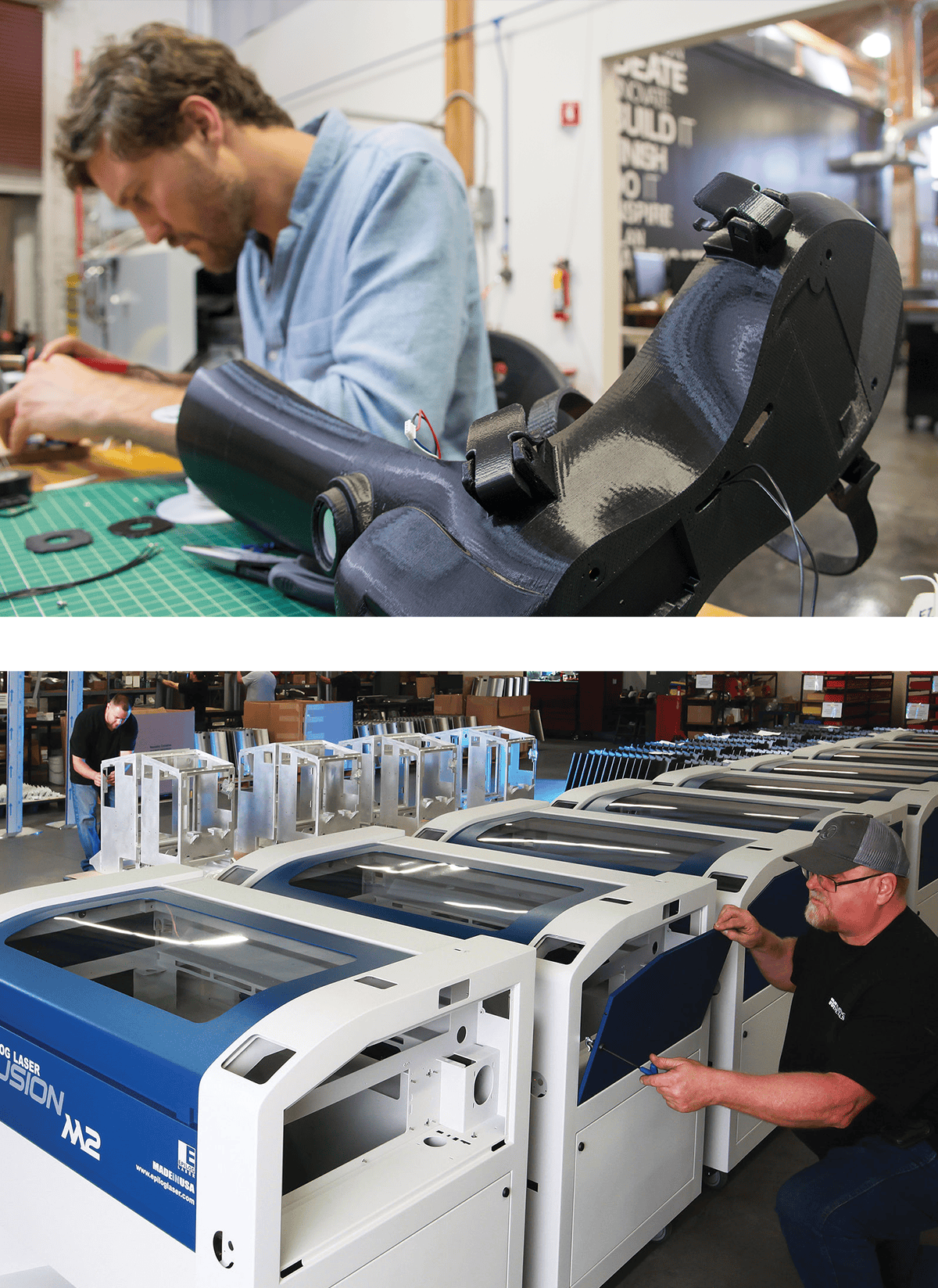

Assembly & Finishing

Fathom’s comprehensive in-house post-processing services allow you to enhance your parts and complete your project to your exact desired level of finish. From prototype mockups for concept validations, to photoshoot-ready production parts, streamline your supply chain with our complete product lifecycle capabilities.

Comprehensive

Project Completion

Fathom Manufacturing offers assembly and finishing services that further enhance the look of your design, helping you achieve specific textures and colors. Our professional finishing services are often used for marketing photo shoots, tradeshows, internal presentations and more.

Whether your project is additive or traditional manufacturing, we offer the ancillary tools and processes to create an optimal finished product.

Don’t see the finishing option you were looking for here? Contact us to discuss your needs.

- Painting

- Powder Coating

- Decals

- Pad Printing

- Screen Printing

- Transfers

- Assembly

- Drilling

- Media Blast

- Gear Cutting

- Customized Shipping Crates

- Grinding/Jig Grinding

- EDM

- Polishing

- Plating (Standard)

- Chem Film (Standard)

- Anodization (Standard)

- AMT Post Pro (Additive Manufacturing Only)

- Arc Welding

- Metal Inert Gas (MIG)

- Tungsten Inert Gas (TIG)

- Resistance Spot Welding

- Laser Welding

- Oxyfuel Welding & Cutting

- Deburring

Levels of Finishing

|

FINISHING GRADE LEVELS |

GRADE LEVEL DESCRIPTION |

ADVANTAGES & CONSIDERATIONS |

|

AA |

High-Resolution Photo-Ready Parts |

|

|

A |

Trade Show or Presentation Parts |

|

|

B |

Concept Models, Aesthetic Experimentation or Part Comparisons |

|

|

C |

Concept Validation & Non-Aesthetic Parts |

|

Considerations for Creating

Aesthetically-Important Parts

Color

Fathom commonly uses the Pantone Matching System and can match custom blended paints to any color code or paint swatch (subject to review by Fathom production manager). Paint is applied using a variety of methods, dependent on color, glossy/matte and the specific texture desired.

Texture

The most common method for selecting texture is by calling out a Mold-Tech texture. Paint textures are approximated to the model—options include light, medium or heavy. Fathom also offers AMT’s PostPro3D vapor smoothing technology finishing for SLS, FDM and MJF 3D printing technologies. This post-processing technique eliminates the need for time-consuming sanding or other surface smoothing processes. Utilizing the PostPro3D for end-use parts is a great option for projects on a tight product development schedule.

Assembly

If your model is comprised of multiple parts, assembly is the final step. If painting is required, colors are often applied to separated components to maintain very crisp, clean lines. Masking is available, but it is a less preferred method, as it can bleed. Models are either glued using an adhesive and/or assembled using fasteners depending on application.

Stock Components

A common aspect of model finishing is the inclusion of stock components such as fasteners and metal inserts. These items are usually applied in the assembly process. In most cases, these additions are for their functional properties. For example, adding a metal threaded insert allows for more durable threads when an item requires screws or bolts in the assembly process.

Artwork

High-quality finished models often need to include lettering and logos. The artwork is applied using a variety of methods depending on the shape of the surface it is being applied to, the number of colors and the level of detail. The most common methods are transfers, stickers, screen prints and pad prints. In most cases, a clear finishing coat is applied to protect the artwork as well as the paint on the model.

Talk to an Expert

Have a tricky color to match, or require intricate assembly procedures? Our craftspeople are ready to meet your assembly and finishing needs. Talk to us today to get started.