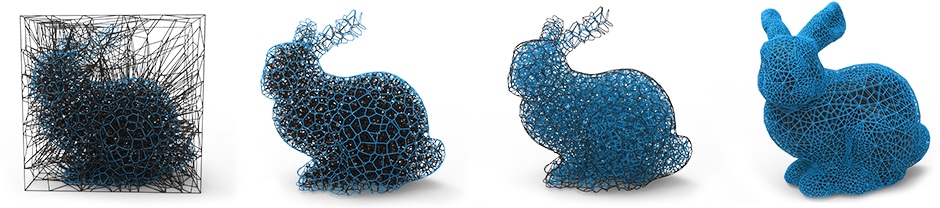

Lattice Design Using Rhino and Grasshopper

The Fathom team is excited to introduce Crystallon, an open source project for creating lattice structures using Rhino and Grasshopper. It was developed by Industrial Designer Aaron Porterfield at Fathom as an alternative to commercially available lattice design software. Porterfield joined Fathom’s design and engineering team in 2015 and is a regularly featured speaker on lattice structures in Fathom’s Design For Additive Manufacturing (DFAM) Training Program.

What’s the obvious and not-so-obvious advantages of Crystallon with Rhino and Grasshopper?

The obvious advantage is the ability to use Rhino’s design environment to generate lattice structures without exporting to 3rd party software, but the extended advantages include the modularity and ability to combine other powerful tools available for Grasshopper.

What’s the inspiration behind making the project open source?

The decision to release it as open source was not only to share it with the community, but to further the development through its users. We realize not all users will have the same applications and needs, so we hope to receive feedback and improvements from users with unique case studies. Each tool is left as a cluster which can be opened and modified at will, in the spirit of open source—in hopes that the community will continue to develop and contribute through the use of Grasshopper forums and Github.

Why do you think it’s important to have this type of software diversity in the manufacturing industry, both proprietary and open source?

I don’t think there will ever be software that does everything you need it to do and diversity is necessary to meet a variety of application types and user needs. The manufacturing industry is only beginning to adopt processes like this, so the software around it is still very immature and only a few experts exist in this field. Most software developers are focusing on specific applications that target high-value customers such as the aerospace industry, but, in doing so, their software becomes limited to only those applications. That is the exact reason I started making these tools. I often have clients with very niche applications that other software just isn’t well suited to handle. I think the best approach to developing tools like this is to make them as modular as possible and capable of working with other tools that have their own strengths, rather than try to reinvent the wheel every time. Generating the geometry (which is all these tools do) is fairly simple, but simulating and optimizing for a variety of applications is very difficult, which is why modularity and leveraging other tool’s strengths makes sense.

Why have lattice structures been a personal focus for you throughout your career?

My focus has always been on computational geometry, parametric design and how these two relate to digital fabrication. My interest in lattice structures started when I finally had access to additive-based machines capable of producing them. At the time, I was an artist in residence at Autodesk’s Pier 9 facility where I had unlimited access to a variety of technologies. I mostly focused on experiments involving what was possible with these systems and how small and/or complex I could make things. That’s where I started developing this set of tools.

When I began working on the Fathom team, we wanted to explore what software was available for lattice structures because it was something our customers were and continue to be interested in. After exploring almost all of the software available at the time (which were all still very new and mostly in beta), we decided to continue my work with the tools I had started to create. Everything has evolved quite a bit since I have continued to create bespoke tools for our customers and their diverse application needs. It wasn’t until the end of 2017 that the Fathom team decided to release these tools publicly as open source to leverage the community for further development.

When does taking a lattice approach make sense?

If you are designing a part that is meant to be 3D printed, you should consider anything that could be possible. We like to say that with additive technologies, complexity is free, which means the process is most likely not limited or sometimes even affected by the intricacies of the design. Without those traditional limitations, almost anything is possible. Lattice structures are interesting because there is almost an infinite amount of application types that would benefit from it.

The most common and obvious application is structural light-weighting, but they can also be used for energy absorption, insulation, heat transfer, filtration and medical applications. If you are using an additive technology to produce the part, it is likely there are many situations where a lattice structure could be beneficial.

What are the advantages? Disadvantages?

I don’t think there is a clear black and white perspective on the advantages and disadvantages of lattice structures. The real advantage, in its purest form, is the ability to manipulate the mechanical properties of a material by changing it’s structure. If you no longer think of a material in terms of its bulk material properties, but in the range of properties possible with different microstructures, you open a huge range of possibilities that you never had before.

You could say the only disadvantage now is the technology behind the machines—what they are capable of and what materials are available. Lattice structures are not ideal for every process at every scale, so, for now, they are mostly used with additive technologies such as SLS/DMLS or SLA/DLP.

What would accelerate the adoption of lattice design?

Since most of this is very new to the manufacturing industry, education is the most important thing that will accelerate the adoption and maturity of these applications. At Fathom, we are teaching a course on DFAM (design for additive manufacturing) where we include a fairly broad overview of these concepts, not specific to any particular software or application. Most engineers in the manufacturing industry aren’t aware of the many advantages that come with 3D printing and additive manufacturing and are especially unsure of where to start and what software to use. Providing a very broad explanation of the concept has been most advantageous because it gets the engineers thinking about how it relates to them and their industry. I have had many engineers come to me after the seminar asking about applications I had never thought of myself. This is how progress will really be made in terms of software development and what industries it can reach.

How would you like to see the use of lattice structures evolve in the next five years?

The industry is very focused on very particular applications at the moment which are becoming more mature, but it is the less adopted applications I am most interested in. I think there are still a lot of things left to discover, so it is just a matter of time and experimentation. This field is evolving quickly. In a very short amount of time, our entire concept of what these are used for, how they are made and how the software should be designed to accommodate that could change. Even within a year or so, I would like to see more time devoted to research on other applications, which will in turn further the development and evolution of the software.

For a Crystallon Rhino and Grasshopper tutorial, visit food4rhino.com/app/crystallon.