- What is Carbon Fiber?

- How is Carbon Fiber Made?

- Carbon Fiber Material Specifications

- What are Thermoplastics?

- What is Continuous Fiber 3D Printing?

- Chopped Carbon Fiber vs. Continuous Carbon Fiber

- What is Fused Filament Fabrication?

- What are the Advantages & Disadvantages of Using Carbon Fiber Filaments?

- History of Carbon Fiber 3D Printing

- Use Fathom for Your Carbon Fiber 3D Printing Project

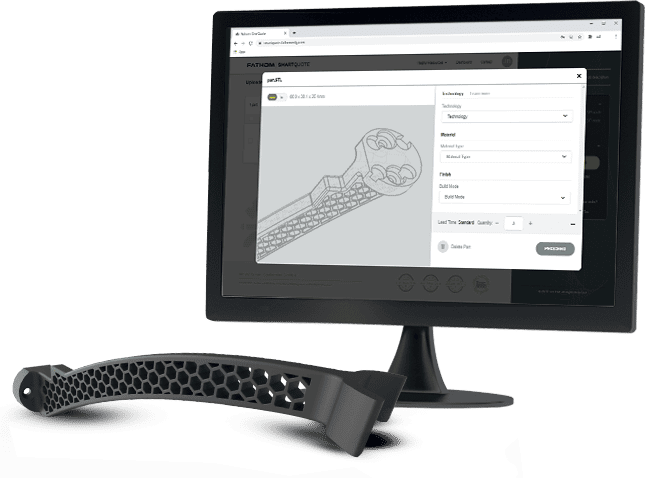

Fathom offers carbon fiber 3D printing services, helping your project produce a high-quality product that is strong, stiff, heat resistant and durable. The advantage of carbon fiber 3D printing is additional strength – stronger than traditional thermoplastics such as PLA or ABS. Some examples of carbon fiber 3D printed parts include tooling, prosthetic limbs, bicycles, automotive parts and more.

What is Carbon Fiber?

Carbon fiber has grown in popularity across many industries because it offers high stiffness, low weight, high tensile strength, high chemical resistance, high-temperature tolerance and low thermal expansion. Carbon fiber is made of carbon atoms that are bonded together in a long chain. This chain is between 5-10 micrometers in diameter. Carbon fiber is stronger than steel, weighs less and is twice as stiff. This means that carbon fiber can be used to optimize performance of parts and is particularly useful for construction, military, aerospace, automotive and more.

Carbon fiber can replace other materials in designs that have unsatisfactory performance or increased lifecycle costs. Some of the products created using carbon fiber include / /

With the advancement of 3D printing technologies, using carbon fiber in 3D printing as a reinforced material has led to higher performance for many applications.

How is Carbon Fiber Made?

Carbon fiber is combined with other materials to create a composite material or carbon fiber reinforced material. The composite is a combination of a polymer, or sometimes ceramic. The resulting material is lightweight and highly durable.

Carbon fiber is produced using the following steps / /

- Polyacrylonitrile is a byproduct of petroleum and is commonly used as a carbon fiber. It is first mixed with other materials. The mix is spun into thin fibers—thinner than a human hair.

- The fibers are oxidized.

- To remove impurities, fibers are heated to 1,000° C.

- The fibers are treated to improve bonding.

- The fibers are sized, coated and spun into yarn of varying thickness.

Depending on the final application, the carbon fiber may be woven into sheets or cut into shorter fibers. Chopped fibers are short fibers less than a millimeter long that are mixed with traditional thermoplastic to create filled plastic. They are commonly used in Fused Deposition Modeling (FDM). Continuous fibers are coated in a curing agent and then laid down in a thermoplastic matrix. They are extruded using a secondary print nozzle in continuous fiber fabrication. Carbon fiber may also be mixed with a polymer for use in 3D printing. To prevent clogging during 3D printing, a hardened steel nozzle is used. Whether chopped fiber or continuous fiber, the result is a material that is stronger and lighter in weight, with an increased level of stiffness.

Some of the popular carbon fiber filaments include / /

- PLA

- PETG

- Nylon

- ABS

- Polycarbonate

Some carbon fiber filaments have been developed for more technical applications. These specialized filaments include Polyether Ether Ketone (PEEK), Polyetherketoneketone (PEKK) and Higher Performance Polymers (HPP). They have an increased strength-to-weight ratio. To print using these materials, the printing parameters of the 3D printer must be adjusted. An extruder is heated to 400°C in order to heat build plates and chambers.

Carbon Fiber Material Specifications

Fathom offers a chopped carbon fiber material option for Fused Disposition Modeling (FDM) technology.

| FDM Material | Lead Time | Optimal Quantity | Maximum Dimensions | Suggested Minimum Wall Thickness |

Finish & Appearance | Advantages & Considerations |

| Carbon-Filled Nylon 12 | 4+ Days | Prototypes, Low-Volume, Short-Run Production | 320mm x 320mm x 610mm | 1mm | Standard Color: Black |

|

What are Thermoplastics?

Thermoplastics are a plastic material that can change state from solid to liquid, and back to solid, without changing chemical properties. They are commonly used in 3D printing technologies because they can be liquified or melted, layered and then cooled into their final shape. Without the addition of carbon fibers, they have a low melting point and are not as stiff or as durable. This is why carbon fiber is necessary for specific applications—it adds strength and overall durability.

What is Continuous Fiber 3D Printing?

Continuous Fiber Fabrication (CFF) is a process in which continuous strands of fiber (carbon fiber, fiber glass, or Kevlar) reinforce a part in order to achieve the same strength as metal, but at a lighter weight. The machine uses two print nozzles. The thermoplastic is extruded to form the shell of the part. Then, the continuous fiber is ironed down onto the thermoplastic. A resin coating fuses the thermoplastic and carbon fiber. The process is then repeated. Parts reinforced with CFF can withstand larger impacts and have weight distributed across their length. CFF is considered more durable than chopped fibers.

Chopped Carbon Fiber vs. Continuous Carbon Fiber

There are a few differences between chopped carbon fiber and continuous carbon fiber. Chopped carbon fiber has a good surface finish and usually costs less. There is not much overlap between fibers, so parts made using chopped carbon fiber are only marginally stronger than traditional 3D printed parts. Continuous carbon fiber has a good strength-to-weight ratio and better stiffness, resulting in a much stronger material than other thermoplastics.

What is Fused Filament Fabrication?

Fused Filament Fabrication (FFF) or FDM is an extrusion-based additive manufacturing technology commonly used for modeling, prototyping and production applications. Classified as a rapid prototype technology, FDM works on an “additive” principle, laying down material in layers. A plastic filament or metal wire is unwound from a coil and supplies material to an extrusion nozzle, turning on and off the flow. FDM is the best choice for jigs and fixtures, molds, tooling and other functional parts that require durability and resistance.

FDM is not only popular amongst manufacturers but is increasingly known by consumers as well. Fused Deposition Modeling has been used for various applications, including medical tissue engineering, rapid prototyping and more. The advantage of FFF is you may reinforce a specific area of a part that requires increased durability.

Fused Deposition Modeling was initially invented and trademarked by Scott Crump (Stratasys) in 1989. The patent did not expire until 2009. To avoid trademark violations, other 3D printing companies began to reference the technology as Fused Filament Fabrication. The two terms refer to the same process.

What are the Advantages & Disadvantages of Using Carbon Fiber Filaments?

There are advantages and disadvantages to be aware of when selecting carbon fiber filament for your project.

Advantages / /

- Lighter in Weight Than Metal

- Increased Strength

- Increased Stiffness

- Good Dimensional Stability

- Increased Brittleness Of The Filament (Depending On Mixture)

- Requires a Hardened Steel Nozzle for Printing

History of Carbon Fiber 3D Printing

In the late 19th century Thomas Edison used carbon fibers as a filament in light bulbs. The Union Carbide Corporation during the 1950s was the first to discover the strength benefits of carbon fiber and what could be achieved through different processing techniques. Carbon fiber has evolved into a popular material for parts that require high performance, including parts made for automotive, aerospace and more.

Use Fathom for Your Carbon Fiber 3D Printing Project

Get an instant 3D printing quote on any 3D project today.

Carbon Fiber Parts In As Soon As 4 Days / / Get A Quote