CNC Turning

-

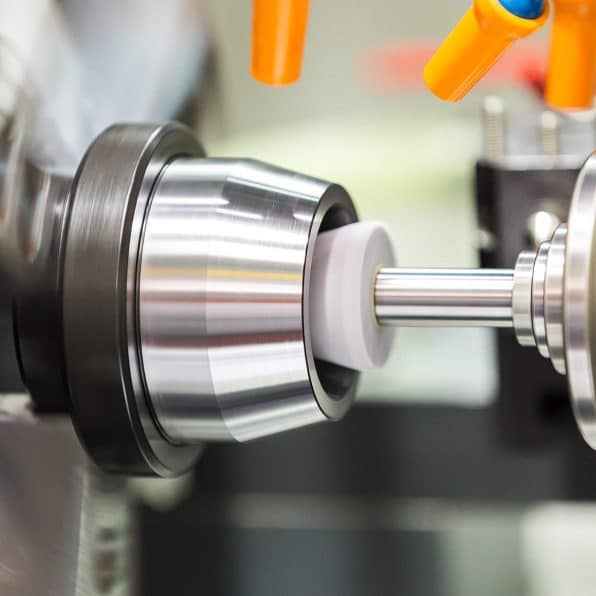

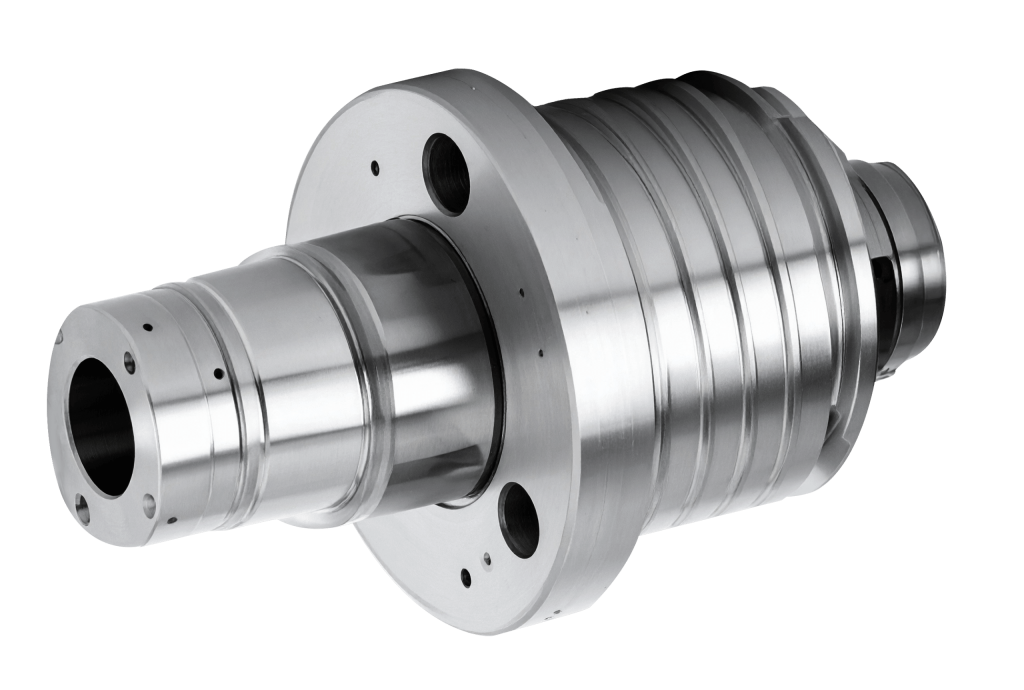

Fast & Consistent Production of Cylindrical Parts

-

Delivers Tolerances as Tight as 0.0001 Inches

-

Exceptional Surface Finishes

Trusted by Industry Leaders

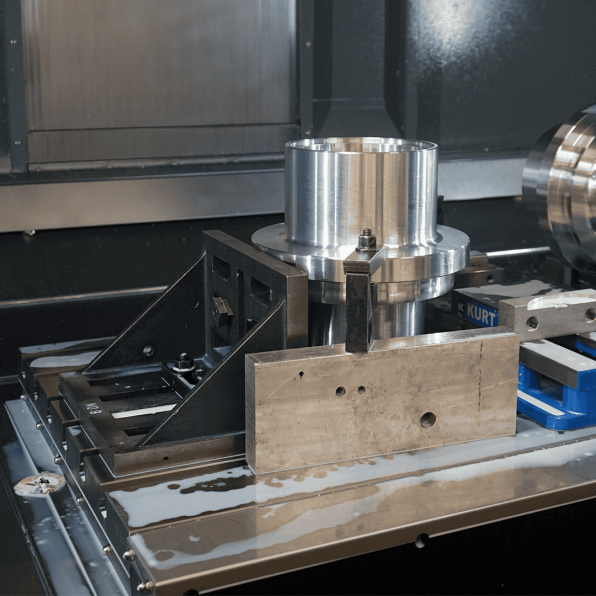

How CNC Turning Works

Is CNC Turning Right For Your Project?

Advantages

-

Precision & Accuracy

CNC turning can achieve extremely tight tolerances and produce parts with very high dimensional accuracy.

-

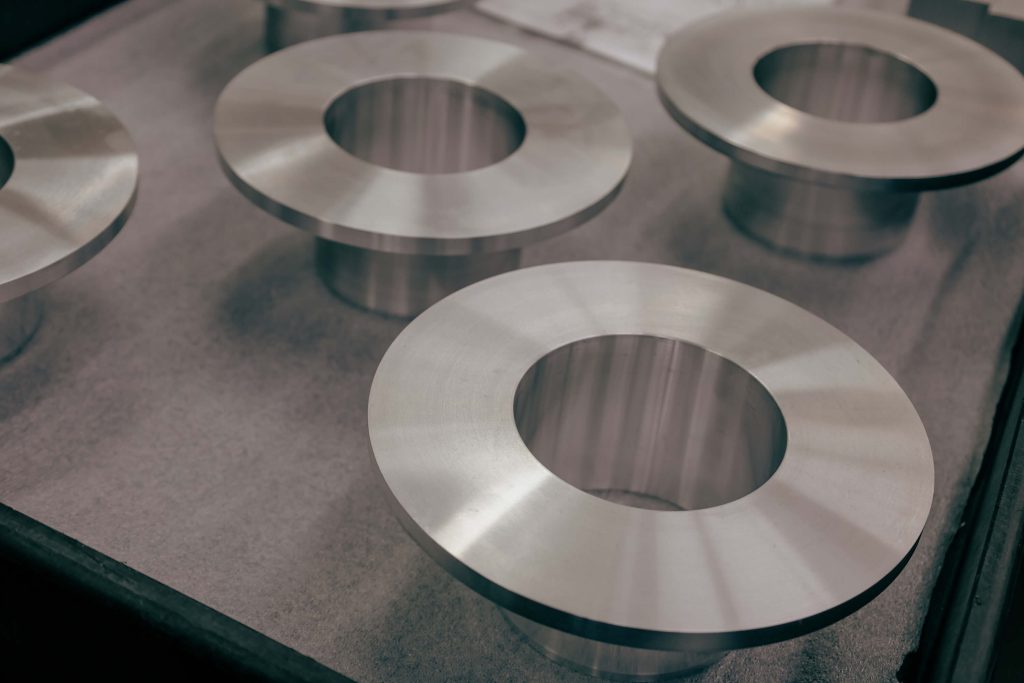

Consistency & Repeatability

The automated nature of the process ensures that every part produced is identical, which is crucial for mass production and consistent quality.

-

Reduced Waste & Lower Costs

The exceptional accuracy of CNC turning translates into reduced rework and waste, which helps to reduce per-part costs.

-

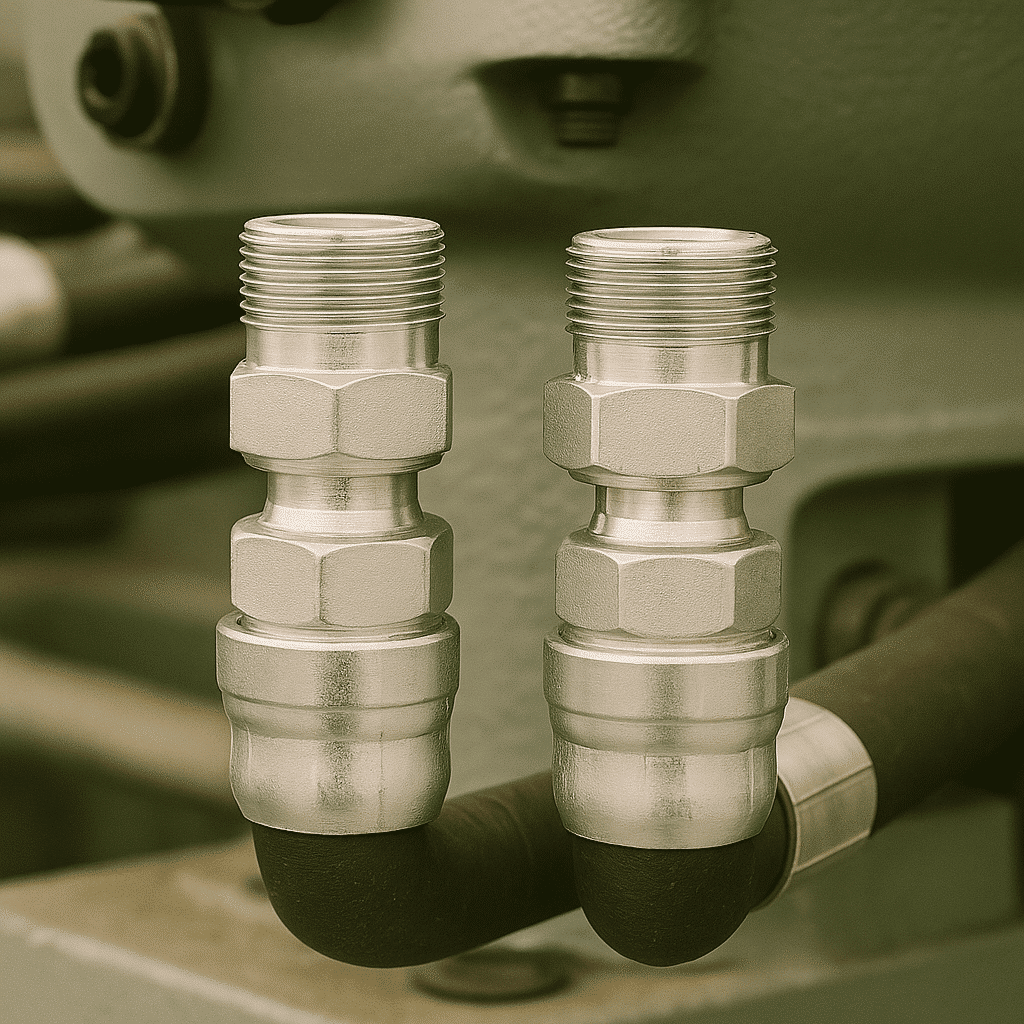

Versatility

CNC lathes can work with a wide variety of materials, including metals, plastics, and composites, allowing for a wide range of applications.

-

Excellent Surface Finish

CNC turning can produce parts with high-quality surface finishes, which is important for many industrial applications.

Disadvantages

-

Only Cylindrical Patrs

CNC turning is restricted to creating cylindrical and rotational-symmetry components, limiting its use for more complex shapes.Also, certain features and geometries cannot be machined using this method. Examples include curved holes, extremely thin walls and straight internal edges,

-

Production Limitations

While precise for single units, the process of producing one unit at a time can make it slow for large batches compared to other methods.

-

Skilled Operators Required

Skilled operators and programmers are required to setup, maintain and troubleshoot CNC turning machines. Mistakes in CAD/CAM programming can cause costly errors or downtime.

Find the Ideal Machinable Material for Your Part

Compare metals and plastics for CNC machining with full property details, tolerances, and suitability notes. Engineered to help you make informed decisions for precision, durability, and performance.

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.