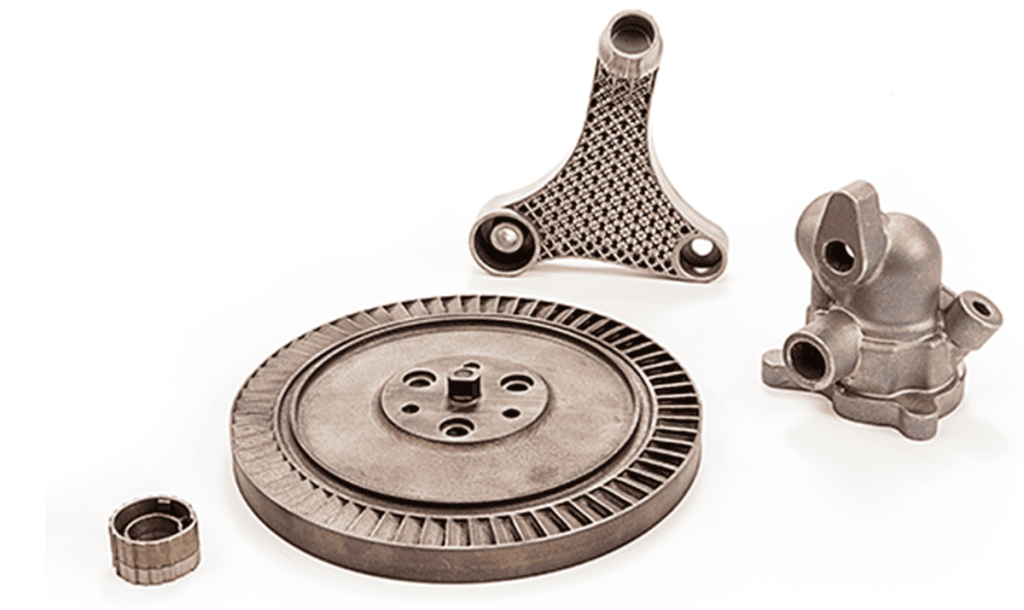

DMLS 3D Printing

-

High-Quality Metal Parts Fast – Without Tooling

-

Perfect for Prototype/Bridge/Low-Volume Production Parts

-

Complex Geometries with High-Performance Metals

Trusted by Industry Leaders

How Does DMLS Work?

DMLS Advantages & Limitations

Advantages

-

Complex Geometries

DMLS can print complex part designs that aren’t possible to fabricate using traditional methods. Engineers are also free to design complex parts without the need for support structures.

-

Excellent Mechanical Properties

The sintering process used with DMLS produces parts that are strong and durable. They exhibit high tensile strength, hardness and wear resistance, making them suitable for demanding applications in the automotive, aerospace and medical industries.

-

Mass Customization

No fixtures or tooling are required to produce DMLS parts. That makes it easy for engineers to modify or fine-tune part designs during production. It also enables designers to create multiple variations of parts as needed.

-

Metal Characteristics are Preserved

The sintering process used to transform metal powder into parts bonds them without melting the metal. That means its mechanical properties remain intact after the part is produced.

Disadvantages

-

Small Build Volume

As a platform for additive manufacturing, the build volume of DMLS is on the smaller side. It’s best for producing small parts.

-

Post Processing

Depending upon the part and its application, DMLS parts may be post-processed using heat treatment, surface finishing and machining.

-

Expertise

As a technology, direct metal printing is a complex additive manufacturing process that requires expertise to consistently produce high-quality parts, and a detailed DFM/DFAM analysis is critical to success. However, Fathom is one of the largest and most experienced sources in North America for DMLS services and can be trusted with your critical production!

Design Smarter for Metal Additive Manufacturing

Explore essential rules for support strategies, feature sizing, orientation, and post-processing when designing for DMLS. Build stronger, lighter metal components with fewer revisions.

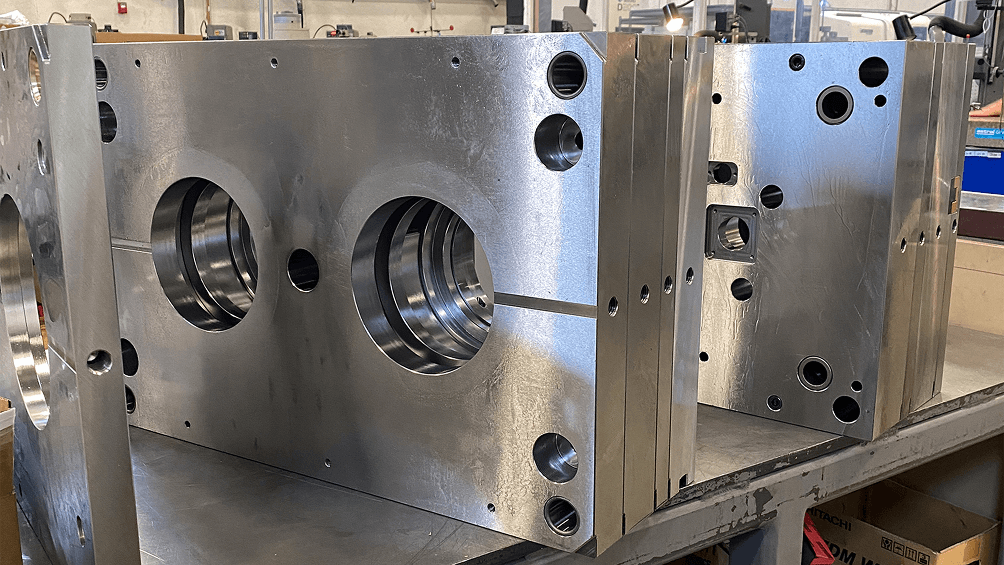

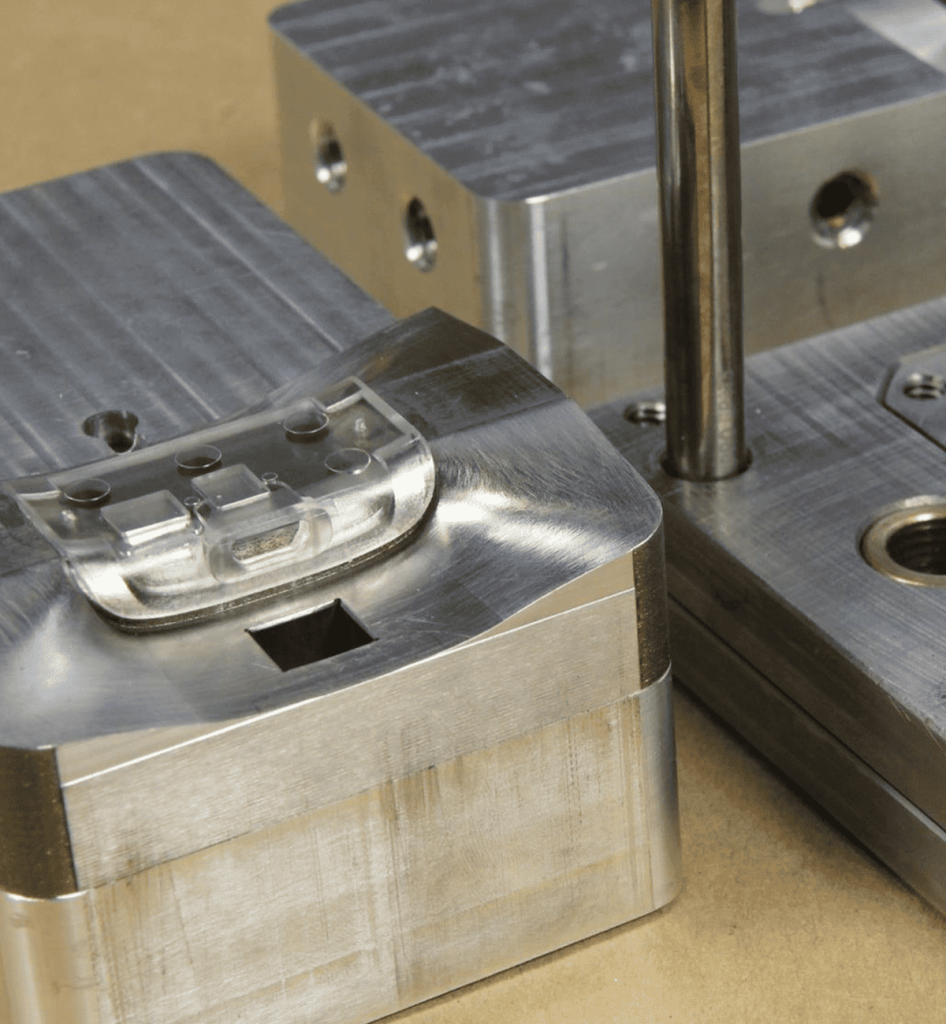

Explore Fathom’s Full Range of Manufacturing Equipment

Download our complete machine list for a detailed look at our capabilities across CNC machining, additive, molding, and fabrication.