Fathom is Laser Focused on Accelerating Customer Time to Market with EOS, EVOLVE Additive Solutions, and DMG MORI

With supply chain issues exacerbated by the current geopolitical and demand shortages, Fathom is committed to creating solutions for our customers. We are laser-focused on outcome-based results, and our customers rely on our deep industry experience to aid in their product development and production. We listen to our customers and are continually investing in technologies that alleviate their pain points within this fragmented market of solutions providers.

This last year has taught Fathom that customers need speed. Not just to get products to market faster, but to catch up to already compressed timelines that were generated as a result of delays.

Additive and Advanced manufacturing is reshaping the industry in the US to address the supply chain disruptions. Fathom, an industry leader in dynamic advanced manufacturing services, is continuing to expand its capabilities to establish solutions that address supply chain concerns. Fathom is increasing its already wide-ranging additive and advanced manufacturing resources to include the Evolve Additive Solutions SVP™ (Scaled Volume Production) Selective Thermoplastic Electrophotographic Process (STEP) technology, EOS M 300 Series Direct Metal Laser Sintering (DMLS) technology, and DMG MORI technologies. We’re heavily customer-focused & committed to quality.

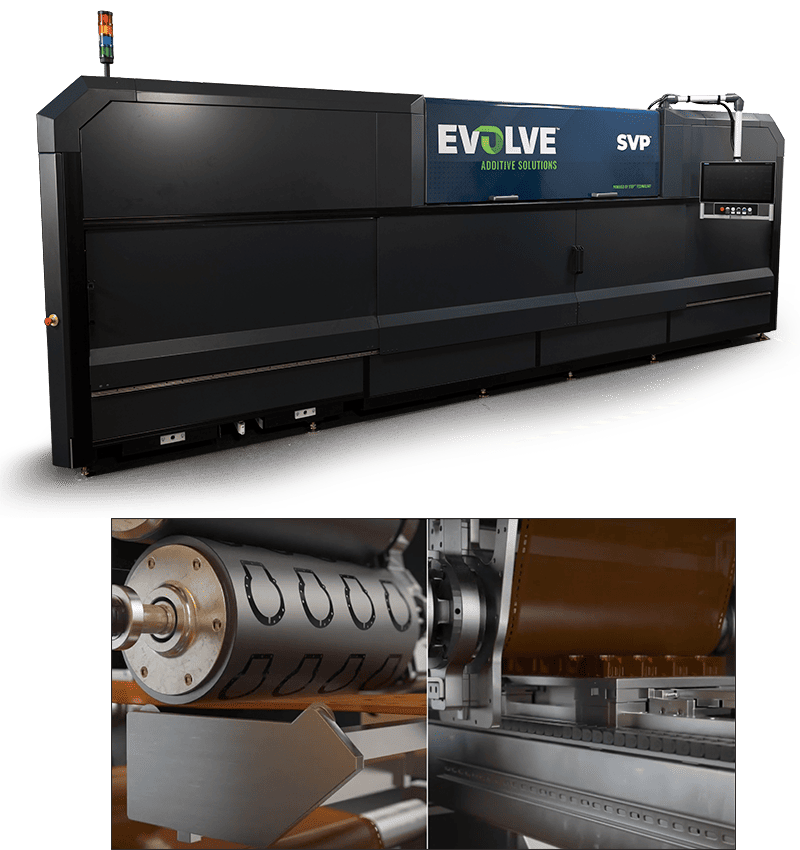

Fathom and Evolve Additive Solutions have entered a key commercialization partnership to bring STEP, Selective Thermoplastic Electrophotographic Process, technology to Fathom’s already comprehensive additive capabilities and nationwide manufacturing network. It is important to pair the flexibility of additive manufacturing with the quality, volume, and scale of traditional manufacturing, and Fathom and Evolve address this with their partnership.

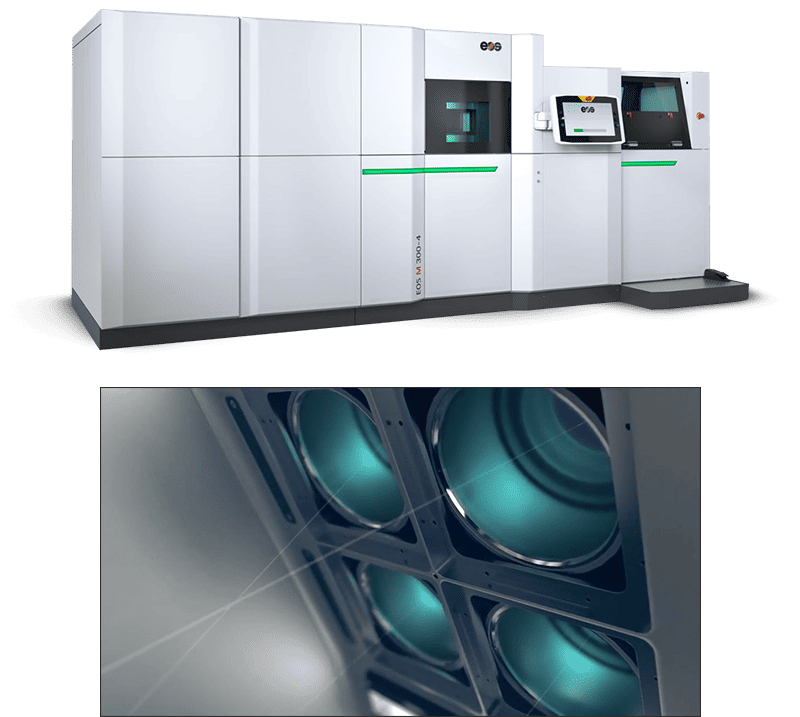

Fathom and Evolve Additive Solutions have entered a key commercialization partnership to bring STEP, Selective Thermoplastic Electrophotographic Process, technology to Fathom’s already comprehensive additive capabilities and nationwide manufacturing network. It is important to pair the flexibility of additive manufacturing with the quality, volume, and scale of traditional manufacturing, and Fathom and Evolve address this with their partnership. The EOS M 300 Series enables DMLS quality with up to 5 times higher productivity. Designed for industrial applications, the EOS M 300 Series offers multiple configuration options combined with safety and security features enabling digital Additive Manufacturing. The platform provides the flexibility to choose the degree of automation that best suits your needs for an optimized workflow as well as the option to easily ramp up as demand increases. It is also less expensive per part compared to single laser DMLS technology. Each of the four lasers can scan the entire build plate to eliminate part seams which is ideal for specific applications such as aerospace components.

The EOS M 300 Series enables DMLS quality with up to 5 times higher productivity. Designed for industrial applications, the EOS M 300 Series offers multiple configuration options combined with safety and security features enabling digital Additive Manufacturing. The platform provides the flexibility to choose the degree of automation that best suits your needs for an optimized workflow as well as the option to easily ramp up as demand increases. It is also less expensive per part compared to single laser DMLS technology. Each of the four lasers can scan the entire build plate to eliminate part seams which is ideal for specific applications such as aerospace components. The monoBLOCK series has a machine concept for every sector. The monoBLOCK has a wide range of capabilities including 5-axis simultaneous machining, highly dynamic high-speed milling, integrated mill-turning, high torque cutting or the broad field of productive parts machining in five axes. What makes this machine unique is its’ ability to produce a 24” cubic component with tolerances that are at .001” or less.

The monoBLOCK series has a machine concept for every sector. The monoBLOCK has a wide range of capabilities including 5-axis simultaneous machining, highly dynamic high-speed milling, integrated mill-turning, high torque cutting or the broad field of productive parts machining in five axes. What makes this machine unique is its’ ability to produce a 24” cubic component with tolerances that are at .001” or less.