Industrial Additive Manufacturing

Fathom offers comprehensive industrial additive manufacturing services to meet all of your needs, from prototyping through production.

Technology & Solutions

for Any Stage of Your Product’s Lifecycle

Manufacturers often need to create special-purpose parts in limited quantities. Using traditional manufacturing methods usually isn’t possible because of the cost and time required to produce tooling. Accommodating design changes is also expensive and time-consuming because tooling must be modified to reflect the updated part design.

Industrial additive manufacturing (AM) eliminates this barrier by enabling parts to be printed directly from CAD drawings, without the need for tooling. This saves a considerable amount of time and money and enables designers to make changes closer to and even during production.

Industrial additive manufacturing is one of the key drivers of rapid prototyping because it enables successive part designs to be printed quickly and affordably. It also gives designers the freedom to manufacture multiple versions of a part simultaneously so they can compare them side-by-side.

Fathom is one of the largest independent providers of industrial additive manufacturing services in the U.S. We specialize in rapid prototyping and short-medium volume production of complex parts.

Industrial Applications of 3D Printed Parts

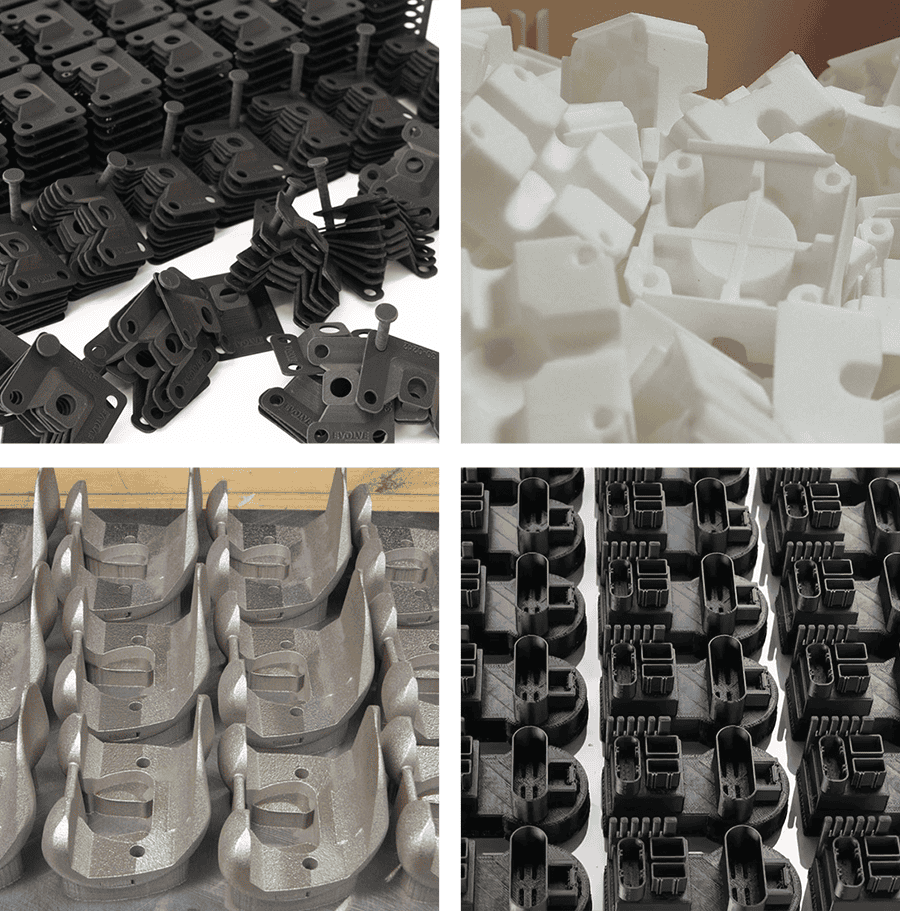

Industrial Mounts & Brackets // From vehicles and aircraft to defense applications and aerospace, industrial additive manufacturing is used to build a variety of mounts and brackets to hold wiring, support body panels and much more. 3D printing makes it possible to quickly adjust their designs as needed.

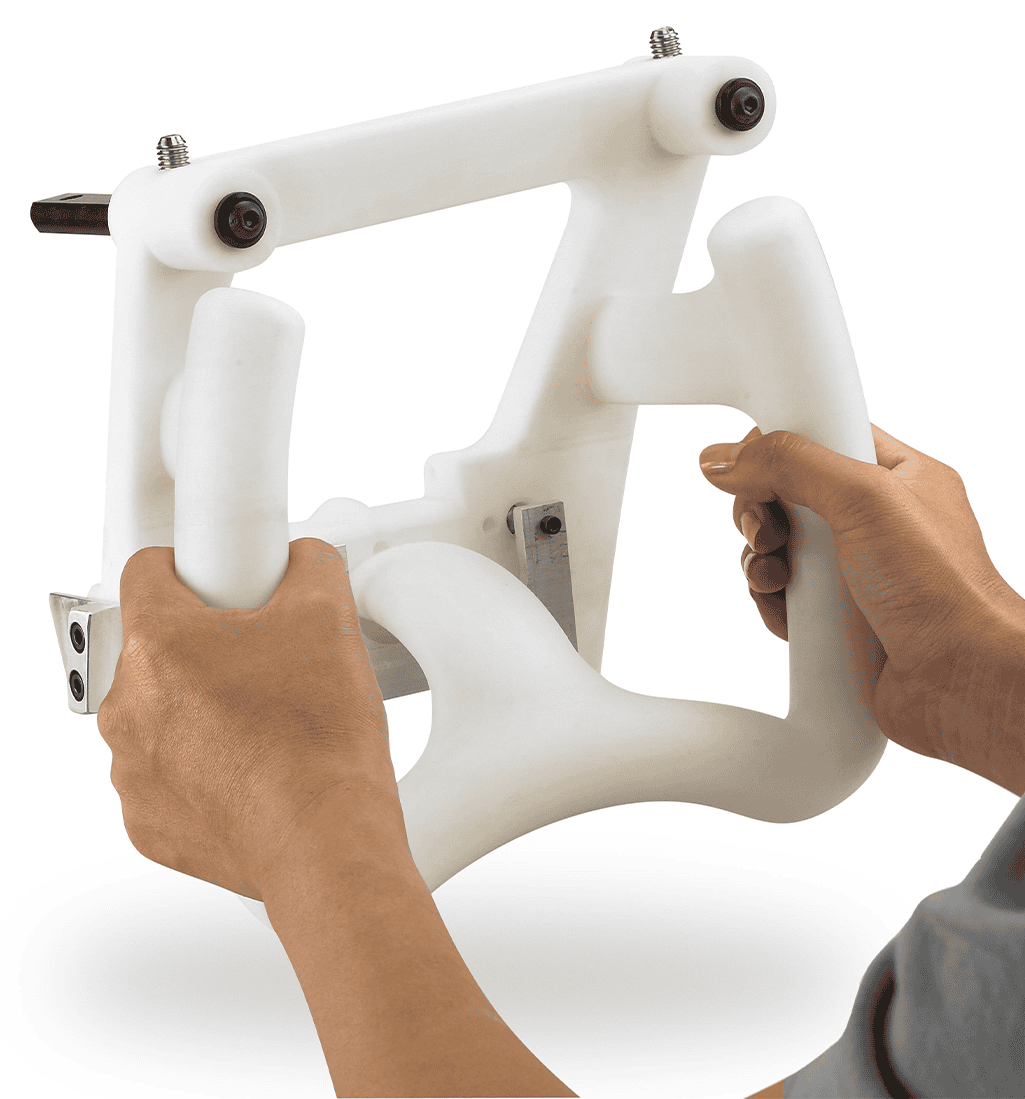

Robotic End-of-Arm Tooling // Industrial additive manufacturing enables manufacturers to print grippers and other end-of-arm tooling as needed and to quickly iterate their designs to hold specific types of parts.

Work-Holding Fixtures // Some 3D-printed parts are so tough that they can be used to hold other parts in place while they are milled, ground or processed in other ways. In other cases, softer materials can be used that will hold a part firmly but gently, so it doesn’t scratch or damage it.

Service & Replacement Parts // In many industries. finding replacement parts for older machines can sometimes be challenging. Industrial additive manufacturing makes it possible to scan the part and recreate it using 3D printing. Printing seldom-needed parts on an as-needed basis also helps OEMs support their customers while also managing part inventory costs.

Complete Assemblies // Frequently, components that need to be glued, fastened or welded together can be combined into a single consolidated part design and can be 3D printed. In many cases, the new part is less expensive than the assembly it replaced. It also eliminates one or more manual assembly steps, saving even more time and money.

Industrial Additive Manufacturing Solutions

Fathom offers five additive manufacturing solutions to meet your needs:

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Selective Thermoplastic Electrophotographic Process (STEP)

Fused Deposition Modeling (FDM)

Fathom also offers extensive in-house post-processing and finishing options for 3D-printed parts.

Why Choose Fathom for Additive Manufacturing?

We have decades of expertise in comprehensive additive technologies.

Fathom has been building parts for customers since the dawn of the 3D printing revolution. We’re now one of the largest third-party providers of industrial additive manufacturing in the U.S., with deep expertise to match.

We combine a full suite of 3D printing technologies with deep engineering expertise and in-house post-processing options. We’ll help you optimize your part designs, material selections and manufacturing processes for optimal results. From rapid prototyping to production, we’ll help you simplify your supply chain and shorten your time to market for new product innovations.

Let’s get started on your next additive manufacturing project.