Triathlete Hydration System

Anvil Studios Uses Fathom 3D Printing in Product Development to Rapidly Iterate Triathlete Hydration System

Anvil Studios is a design firm operating out of Seattle’s Capitol Hill neighborhood. With experience in diverse industries from housewares, consumer electronics and professional equipment to fitness and furniture, Anvil has become a product development powerhouse, designing for world-class brands such as Starbucks, Microsoft, Siemens and Oster. In developing the Nathan AP Pro Sports Bottle, a specialized hydration system for triathletes, Anvil turned to Fathom for their accelerated 3D printing needs to rapidly iterate on their conceptual design.

Fathom sat down with Anvil’s Treasure Hinds and Greg Janky to discuss the Nathan Bottle project, their design process and how 3D printing has changed their design cycle.

How did the AP Pro Nathan Sports Bottle come to be? When did Anvil get involved in development?

This was a category that Nathan Sports had been looking to get into in order to be more competitive in the Triathlete market. Anvil was involved from the beginning. We were referred to the client several months before their decision to approve this program. When it came time to kick the program off, we were there ready to go.

In developing the AP Pro Sports Bottle, what were some of the unique challenges you faced?

The design brief called for an aerodynamic water bottle that could hold 20oz of water, fit any configuration of aerobars and be easily attached/removed from the bike. We began our initial research by purchasing all of the triathlete water bottles on the market so we could attach them to our bikes and get a feel for what was and wasn’t working. Once we had firsthand experience with these bottles on a triathlete bike we visited our local Triathlon bike store and picked their brains. They allowed us to measure all of the handle bar set-ups, configurations and dimensions of each of their clients’ bikes being serviced in their shop. This was invaluable experience and data that really gave us a great starting point for our ideation problem solving.

For independent design firms, what does it mean to have access to industry-leading 3D printing technologies, materials and innovative manufacturing techniques during product development?

Speed and accuracy. Fathom is crucial to our design and development process and the ability to send CAD files off in the afternoon and pick up parts the next morning allows us to iterate quickly. This allows us to constantly restructure and effectively review the physical reality of our latest ideas with clients.

Fathom often utilizes multiple legacy and additive manufacturing technologies when helping a customer accelerate the product development process—tell us about the technologies you used with the Nathan bottle.

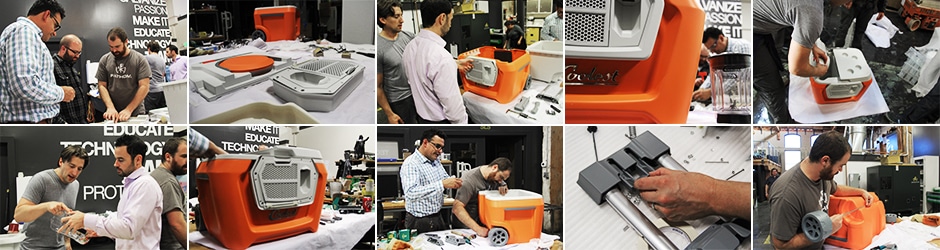

Initial volume studies were created using basic 3D prints to validate overall size and shape, but we quickly moved to PolyJet 3D printing to iterate and refine the cage mounting system, the self-centering system and how all of the components would come together and work in unison.

How does the design cycle change when additive technologies are included? How does this affect the overall product development timeline?

In this case, using 3D printed parts allowed us to not only have realistic representations of our designs to review with clients, it also provided us with models that we could take back to bike shops to get feedback from actual users. We were able to mount the designs to bikes and get a feel placement of the straw mast and refilled opening. We were also able to quickly iterate on our patented self-centering mount system to test for the wide range of aerobar spacings, angles and configurations. I don’t think the design would have been as integrated and simple without the ability to rapidly prototype and validate our concepts.

Do you have any advice for fellow professionals in product design that are incorporating 3D printing into their process?

Hit print early and often! Looking at a screen will only get you so far. There is no substitute for real parts in-hand to interact with and prove/disprove a thought.

What was the total timeline for the AP Pro bottle from beginning to end of product development? How many iterations did you design and test? What would this timeline have looked like if the Anvil team had to rely on traditional manufacturing methods?

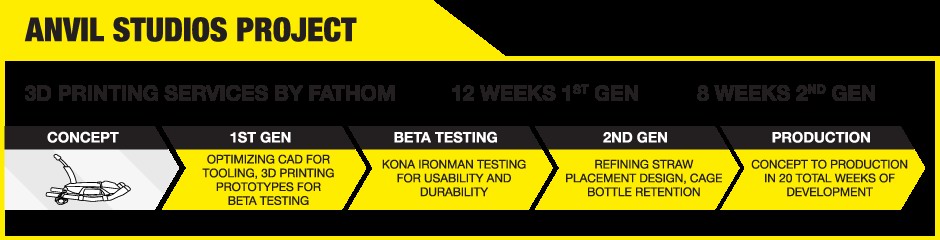

The first generation design lead time was about 3 months start to finish. The second generation timeline kicked-off soon after the Kona Ironman Triathlon (pictured below—participants race into the water during the triathlons first leg) and lasted about 2 months. It’s rare that a client has the foresight to approve prototype tooling for a Beta unit prior to launching, but our client wanted to be “the best” in this category.

There is no substitute for real parts in hand for validation. The insight we learned from having world class triathlete Andy Potts train and race with the prototyped tooled product for the Kona Ironman Triathlon was crucial. As a result, we were able to quickly design a 2nd generation product to address some critical issues, such as straw placement and bottle retention in the cage and that is what made it to market.

To learn more about Anvil Studios and the AP Pro Sports Bottle, visit the Anvil website: anvil-studios.com. To read more about accelerated product development with Fathom, check out other blog posts documenting our work with women’s health startup NextGen Jane, NFL fitness product startup Recoup Fitness, mobile charging company Doblet and phone-based virtual reality company Figment VR.

Have a project that could use a boost? Start a conversation with us today!