Custom 3D Printed Shoes / / 3D Scan Data, The Future of Retail

Seattle-based product development firm, came to Fathom looking to bring a unique shoe concept to life. Not just any design, but one that demonstrates how 3D printing could impact the future of the retail experience, point-of-sale manufacturing and the product design process. Dubbed DNA by their design team, the companys project uses footwear to examine the opportunities around ergonomic/biomechanical tailoring. Typically, the athletic footwear market relies on set sizing to accommodate the most common foot shapes and movement styles. For many people, the average fit does not equal the best fit. To create a more user centric design, footwear needs to be based on each customer’s feet. [ source ]

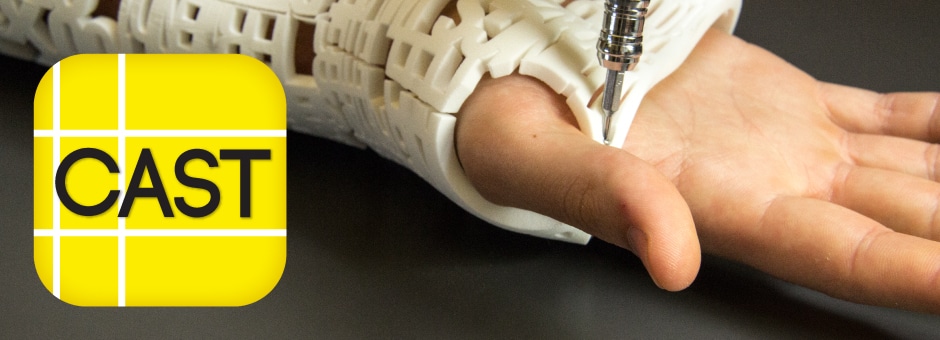

The DNA shoe was 3D printed by Fathom at its advanced prototype fabrication and low volume production center in Seattle using PolyJet Technology on an Objet500 Connex3 — a digital combination of rigid and flexible materials were used to achieve the ideal durometer (VeroClear, VeroYellow, Tango+ and TangoBlack+).

THE CONCEPT

Picture yourself shopping for a new pair of shoes. At the store, each foot is 3D scanned then you put on a pair of special sensor shoes for a test run or walk. The movement captured by the sensors in the shoes is combined shortly after with the 3D scan data. From there, algorithms are used to translate the data into a customized and personalized form. Next, you get to customize the materials, colors and textures of the shoe (or maybe you have a preselected design already on file). Then, while you wait, the shoe design goes to print.

Costly tooling and expensive skilled labor has prevented the mass market from owning custom-tailored products. The goal of the DNA concept is to illustrate a path where 3D printing can enable customers to engage in the design process and create a personalized product. Automating the process through algorithm-driven design and 3D printing will make it economically viable to a much larger audience.

THE REALITY

Company’s DNA shoe explores how 3D printing will evolve the retail experience for customers and change the way products are designed and manufactured.

Before this concept can become a reality, there are advancements that need to take place in 3D printing technology. For example, the materials currently available dont offer the durability or softness necessary for wearing every day or for athletic use. Further study is also required to ensure the materials are biocompatible and safe for consumers. Today, the cost and time it takes to print a pair of shoes are both too high. However, the 3D printing industry is evolving quickly and while material challenges may prohibit immediate implementation, user-driven rapid manufacturing will be realized in the near future. [ source ]

START A CONVERSATION

Talk with an expert today about your application challenges: Email. The Fathom team is helping companies make the unmakeable through advanced manufacturing techniques. Both our Seattle and Oakland locations can help your company innovate faster and more efficiently. We strive to be our customers’ preferred partner by providing best-in-class equipment, services and support.