5th Grader Designs His 3D Printed Arm

Fathom Design and Engineering Teams Help Fifth Grader Create Custom Prosthetic for Kayaking, Swimming and Horseback Riding

KIDmob is a mobile, kid-oriented design firm based in the San Francisco Bay Area. A nonprofit organization, KIDmob consistently coordinates events that help kids take active creative roles in designing solutions for challenging problems. KIDmob recently held a prosthetic workshop on the Embarcadero in San Francisco and Fathom was eager to take part.

Superhero Cyborg, the prosthetic design event series hosted by KIDmob, aims to re-frame the discussion around limb difference and connect children with professionals and enthusiasts in 3D printing design, engineering and production.

Per a recent article in The Atlantic:

What if we viewed a limb difference as an opportunity to invent rather than a loss to overcome?

The children involved in the program often have different ideas than adults on what makes an ideal prosthetic, viewing the design freedom provided by 3D printing as a chance to create the arm they’ve always dreamed of—violin holder, Lego attachment, weight stabilizer, kayak paddle holder, video game remote, horseback riding attachment, swimming fin, etc.

Kids involved with KIDmob have worked with volunteer professionals to develop all these attachments and many more, oftentimes changing the perceptions of their peers, friends, family and even their own views of their limb differences. Again, from The Atlantic: KIDmobs goal is not to solve all of their problems in a week-long workshop, but rather to empower its students to imagine problem-solving possibilities.

Fathom MEETS DAVID

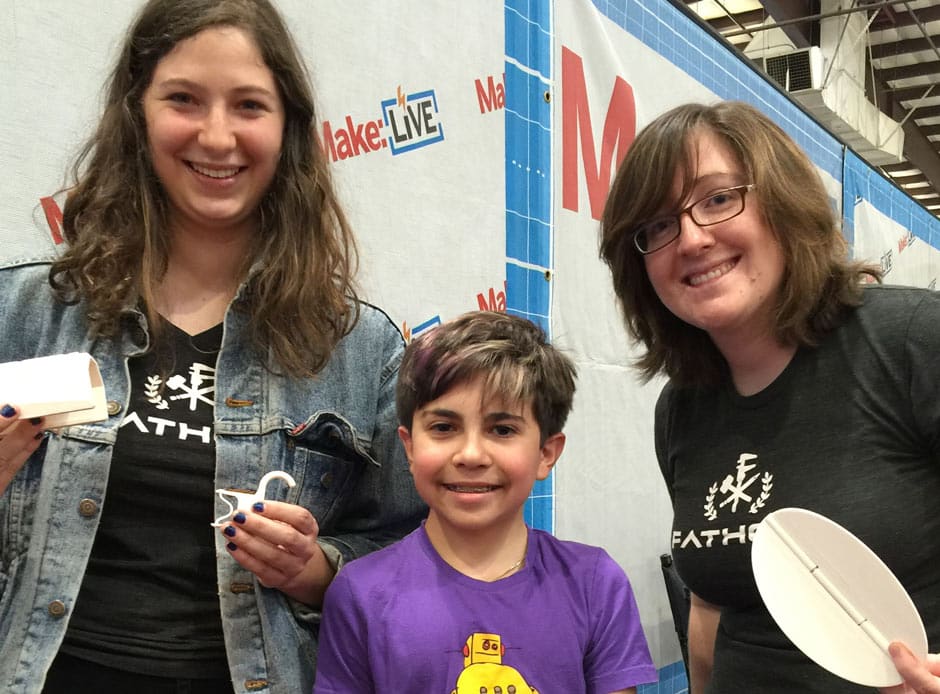

David Botana, a voracious fifth grader from Indiana, had one of the most challenging cases in his Superhero Cyborg group. Fathom Mechanical Engineer Bethany Casarez and Industrial Designer Ava Decapri were paired up with David to help him create an advanced prosthetic.

David (pictured above) is a very active kid and participates in many different sports, so he had many ideas for splint attachments for his custom prosthetic. David, Bethany and Ava narrowed the attachment concepts down to three: a horseback riding attachment, an attachment for using a kayak paddle and a fin-like attachment for supercharged swimming.

At this time, there are no commercial solutions for David who wears a splint but would prefer to have a kind of sport prosthetic—all of the sport prosthetics on the market are designed for people who are missing their entire hands and have fully developed forearms. David had a unique prosthetic case compared to other kids involved in the program. He is missing his radial bone in his left arm, which is less developed than his dominant right arm.

David’s concept was definitely the most complex and ambitious in terms of mechanical durability, dimensional accuracy and resolution—and really needed to be designed and fabricated by people with deep knowledge of 3D printing.

THE FINAL PROSTHETICS

David needed all the attachments to be modular so that he could wear one splint and simply clip in different attachments when different situations arose.

David is a unique case, in that his arm needed to be in a prosthetist-designed splint to provide support at all times, said Decapri, This is a more complex medical requirement than most of the other children in the program and a challenge that we were excited to take on.

The horseback riding concept was a hook that attached to David’s splint that would allow him to hold the reigns with his left hand and ride English Style, where the rider holds both reigns, something David hasn’t been able to do previously.

For the kayak paddle concept, Fathom decided to try two different designs. The first kayak attachment was a snap fit clip that fit around the paddle and allowed a quick release with a cord. The second design was a partial ring lined with rubber that flexed open and relied on friction to hold the kayak paddle in place, but also allowed for the paddle to pop out with enough force applied. The second concept proved to be stronger and the team created the attachment to allow David a smooth paddling motion.

The swim fin attachment was inspired by TRS prosthetics. The design allows the fin to fold in half when being drawn out of the water, reducing air and water resistance and expand when pulled down through the water, creating greater pull power and speed.

All three attachments have proven to be successful in allowing David to pursue the sports he loves.

It was great to see David so confident about his limb difference, feeling empowered by his new design and fabrication skills and inspired by the people who rallied around him, said Decapri.