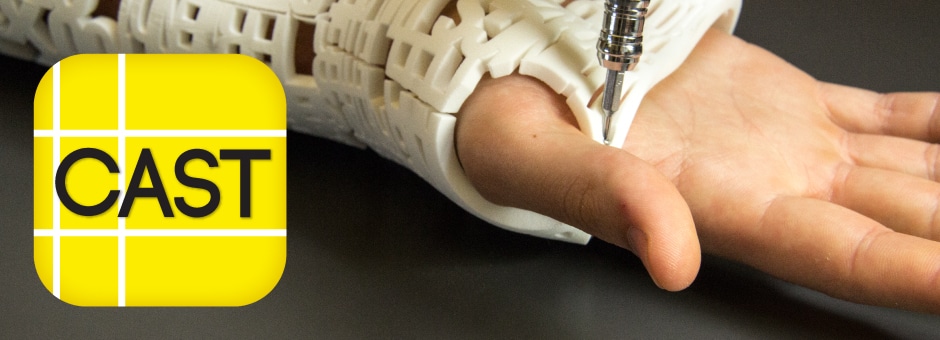

3D Printed Cast Materials / / Arm Cast Design Material

WHAT IS THE #CAST 3D PRINTED CAST PROJECT?

#CAST (pronounced “Hash Cast”) is the new way to customize your broken arm cast with personal messages aggregated from your family and friends through social media. A 3D Printer cast comes from using the latest in advanced manufacturing technologies and 3D CAD software, an arm can be 3D scanned at a doctor’s office and a one-of-a-kind cast made in a breathable nylon material using an additive technology called Selective Laser Sintering (SLS).

Using the #CAST mobile app, users can approve or reject personalized messages collected through their preferred social networks. Once the maximum amount of characters allowed are approved by the user, a custom fit design is generated and built then delivered to their medical facility and fitted on the user by a specialist.

Q&A WITH AVA DECAPRI, INDUSTRIAL DESIGNER AT Fathom

Why did the Fathom team take on the #CAST project?

Ava DeCapri: The #CAST project was inspired by the influx of 3D printed casts in the additive manufacturing community — headline-making applications such as Osteoid, the 3D printed cast with healing ultrasonic vibrations created by Turkish student Deniz Karasahin and the Cortex Cast by student Jake Evill. Both examples utilize 3D printing technologies in innovative ways. It’s great that the ability to scan an arm for a closer fit is possible and very accessible. Plus, the durability and waterproof qualities of the 3D printed material make it ideal for a medical application like a cast.

While discussing the amazing benefits of the various 3D printed cast designs, we became very focused on the users experience from an interactive standpoint. It’s classic to see personalized notes written in marker on a traditional cast. That’s when we realized a big part of the user experience was missing. We asked ourselves, how else could 3D printing uniquely aid in elevating a user’s experience? The #CAST app that works alongside the 3D printed cast, provides that unique experience for the user while still benefiting from the innovative structure that improves healing and comfort. Our goal was to create a cast concept that was familiar, yet exciting and innovative.

What challenges did you encounter with the #CAST project?

Ava DeCapri: The main challenge with the #CAST was translating the text from the #CAST app into a supportive structure. We experimented with different methods of translating the text to the cast surface in RHINO CAD software. The design team finalized a way of using paneling tools and manipulating control points based on the break point identified on the original scan. This method worked well, as we were able to create denser letter groupings around the break, where more support was needed and airier sections where support was less crucial. Having this flexibility to customize the density of the cast allows for a breathable, lighter and all around more comfortable structure for the wearer that’s built out of personal messages just for them.

What do you find most interesting about the #CAST project?

Ava DeCapri: The coolest aspect of the #CAST concept is definitely the inclusion of social media in a medical application. We are taking something that is usually a big bummer, breaking your arm and turning it into a fun and social experience. Just like when your friends and family draw on a traditional cast with markers. Even better with #CAST, anyone from anywhere in the world can “sign” a person’s cast. It has the potential to not only heal your arm more efficiently, but also uplift your spirits.

Can Someone Get a #CAST today?

Ava DeCapri: Sort of. This was an opportunity for Fathom to demonstrate what is possible with current technologies, an example of the tools and expertise we make available to our customers . So, can someone order a #CAST today? No. But could a private physician work with Fathom today on making this available for their clients? Yes. Our team works with companies to put satellites into orbit, electric cars on freeways and a full spectrum of devices into people’s hands and homes. I really enjoyed working on this project because much of what Fathom works on for its clients is under NDA. Rarely do we get the opportunity to openly talk about the cool applications our team is a part of, so it’s exciting for me to be a part of this public project.