National MFG Day Highlights 3D Printing

Additive Manufacturing Production Center in San Francisco Bay Area One of 840 Events Focused on Manufacturing Across the Nation— By Jennifer Wadsworth, Fathom Correspondent

In studying cell culture, the size and shape of the petri dish influences the results. Tough thing is finding the right dimensions per project, biologist Tom Zarembinski explained Friday during a visit to Fathom 3D printing studio in Oakland, Calif.

Its important to a studys results that you find the right size cell dish, said Zarembinski, a researcher at BioTime. So I had this idea that 3D printing might be a good way to make custom size petri dishes.

Thats what brought him to Fathom on the second annual Manufacturing Day Oct. 4, when hundreds of manufacturers across the nation opened their doors to educate the public about what they make. After an hour-and-a-half tour of the production center learning about additive manufacturing, Zarembinski was set on ordering those custom cell dishes to aid his research.

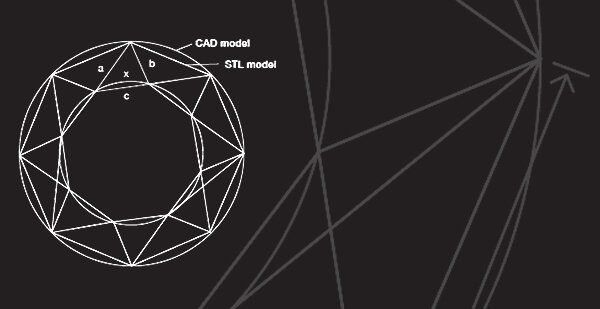

Its so convenient, he said. Ill send over a CAD file, theyll print it out and I can just drive over here to check it out. This is exactly what I was looking for.

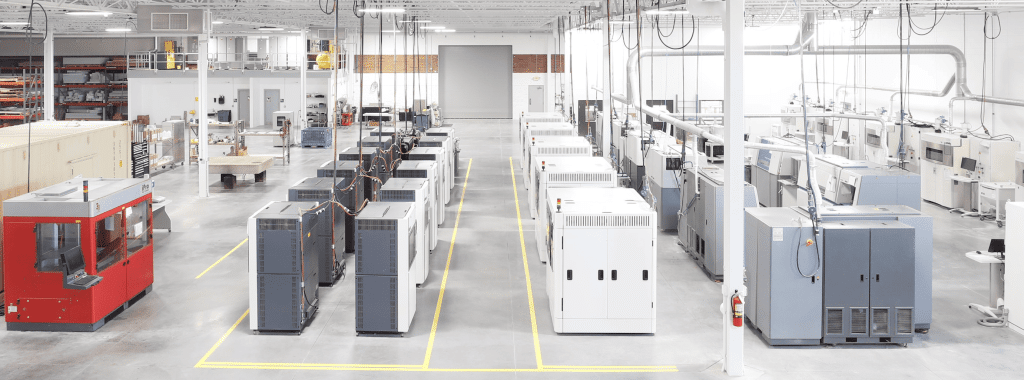

Zarembinski was one of a few-dozen people who visited Fathom, the San Francisco Bay Areas largest 3D printing and rapid prototype production center and top performing Stratasys 3D printer distributor of Northern California and Pacific Northwest. Others included investors, engineers, entrepreneurs and sales reps from various industries. 3D printing specialists took groups around the vintage foundry building to demonstrate and discuss the form and function of the various technologies, from PolyJet, Fused Deposition Modeling, Selective Laser Sintering and Direct Metal Laser Sintering.

Attendees got to handle the results of sample prototypes: a polymer bike chain, a ball of fully functional gears and a model car made from various plastics. Fathom account manager Preeya Singh explained the possible complexities of rapid prototyping, how in a matter of hours you could have a functional model of your potential product. How parts could be programmed to print out soft and rubbery or firm. A 3D printed skull she showed had clear plastic bones and white opaque teeth — all printed out at the same time.

You could start printing something when the doors close at night and have it be ready by morning, she said. Its very fast.

Some were already familiar with the technology. Others said they came in with only a vague idea and left convinced in the technologys power to revolutionize manufacturing.

We like what we see, but even more we see what this could be, said Stephen De Marti, a Comerica banker who scouts out promising businesses to finance. In six hours you can go from a computer file to a fully functional prototype. Thats amazing.

This years Manufacturing Day, an event promoted by industry groups like the National Association of Manufacturers and the Manufacturing Institute, saw more than 840 events in 48 states across the nation and some in Canada.

For more information about Manufacturing Day, visit mfgday.com. For more information about 3D printer sales and rapid prototype services, visit the Fathom get-a-quote page at studiofathom.com/get-a-quote.