Streamline with GrabCAD Print

Accompanying the launch of the Stratasys F123 3D Printer Series, new GrabCAD Print software simplifies the 3D printing process with an intuitive workflow, automatic file healing and native file imports. FDM-based systems currently compatible with GrabCAD Print include:

- Full Support / / uPrint SE, uPrint SE Plus, Dimension 1200es, Dimension Elite, Fortus 250mc, F123 Series

- Limited Support / / Fortus 380mc, Fortus 450mc, Fortus 900mc

We sat down with Tom Kloucek, Additive Manufacturing Production Manager at Fathom, to learn more about the new software platform and its many advantages—also, check out the ebook available on GrabCAD Print from Stratasys.

What are the best new features of the GrabCAD software? How does it improve user experience?

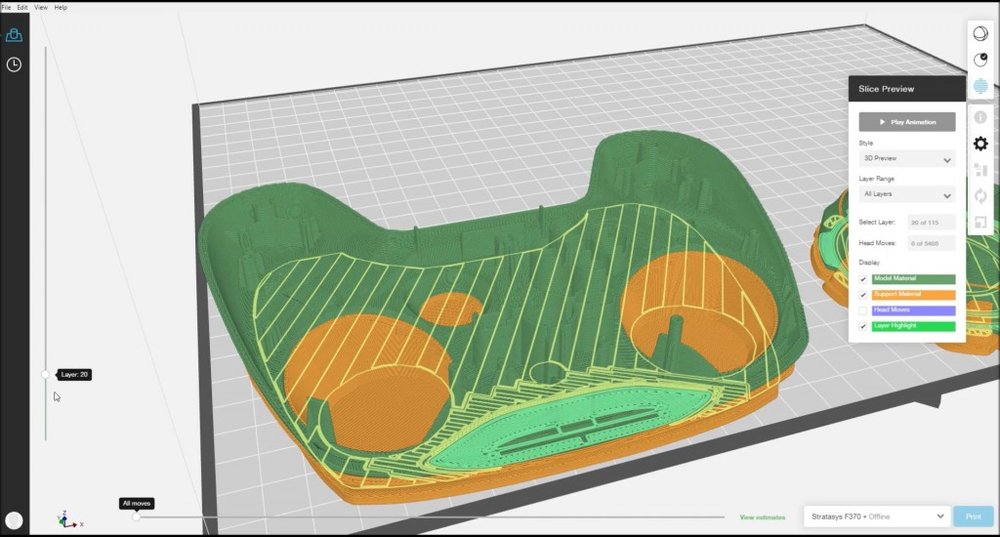

Kloucek—The visualization of the print tray is amazing. It makes it really easy to understand how the machine prints different geometries.

GrabCAD Prints ability to print from other solid files other than STL files will save people as step. Now, you won’t have to manage the part you are building in CAD, plus a list of STL revisions. You can 3D print straight from SolidWorks, so you are always printing the most recent version. It saves a step in the digital workflow and saves a lot of time, especially if you have a high quantity of parts to 3D print.

What will users notice most frequently about 3D printing with the new GrabCAD software?

Kloucek—The most noticeable change with GrabCAD Print is the simplified interface. All the tools are contained in one view. The previous software had multiple tabs of workspaces or multiple programs to take a part file from STL to a print. GrabCAD Print has all the tools in a single view and lays them out intuitively.

How does the automatic file healing function in comparison to what was available in previous software? Approximately how much time can be saved for a typical project thanks to this new feature?

Kloucek—Using previous software, heal filing was all done manually—there was no automated file fixing. GrabCAD Print has picked up on some small faults that would not have been flagged by previous software, which can be the difference between a successful or failed build.

In regards to print queue organization, is there anything the new software does that stands out?

Kloucek—The new software is quite adept at build queue management. I can effectively manage multiple builds for more machines, with clear visuals of all the connected build trays. It compares well to other additive management software and is highly cost-effective.

GrabCAD Print has the added benefit of actually being networked within the machines, so you can start 3D printing as soon as youve planned the build. You can also organize all your part files together into multiple build trays.

Start a conversation with Fathom to chat with our experts about the new GrabCAD Print software and its easy-to-use functionality or request a production center tour to test-drive the software yourself!