3D Printed Prosthetic Hand / / Helping Hand for Isabella

Getting 3D Printed Prosthetic Hand Inspires Young Girl’s Curiosity in STEM— Care Bears, Enable Community Foundation and Fathom Team Up to Boost Isabella’s Confidence for the First Day of Kindergarten

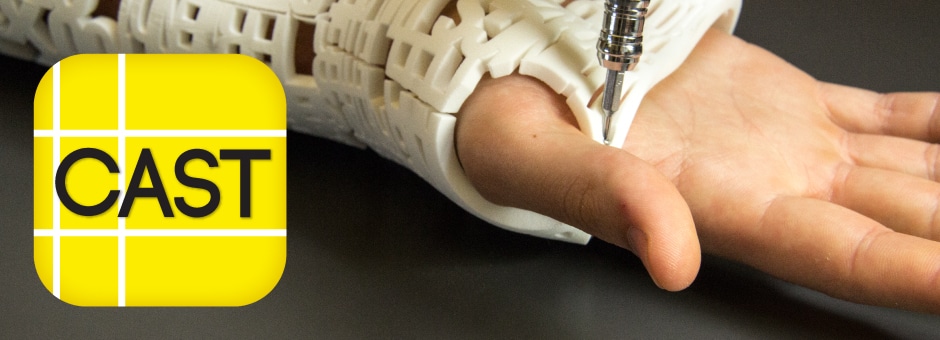

Born with a shortened forearm and an underdeveloped hand, activities that come easily to other children are more difficult for four-year-old Isabella to perform on her own. Through the e-NABLE online prosthetic community, her family and Fathom matched up to expand this soon-to-be kindergartener’s capabilities—the prospect of elementary school was a scary one for both Isabella and her concerned family.

Through a partnership between 3D printing experts Fathom and the non-profit Enable Community Foundation, Isabella feels more confident than ever—the first day of school does not seem as intimidating as it once did. Isabella feels more confident than ever.

She is looking forward to showing off the bright pink, Care Bears™-adorned 3D printed hand in kindergarten next year. When American Greetings found out about the project and Isabella’s love for the Care Bears (in particular Wonderheart Bear), they quickly delivered artwork for the hand and donated a basket of Care Bears toys to help make the presentation truly memorable during the Fathom team’s visit to the family’s home in Bakersfield, CA, last month.

“The e-NABLE and Fathom teams embody what Care Bears are all about—love, kindness, caring and sharing,” said Sean Gorman, President of American Greetings Entertainment. “Our team was touched by Isabella’s story and are so happy that the Care Bears could help make this moment so special for her.”

“Children are very self-conscious about being different than their peers,” said Michelle Mihevc, Fathom Principal and Co-Founder. “The 3D printed prosthetics don’t just give them mobility. They’re also cool and something they can be proud to show off. I think this is the best part about it.”

Not only is the design open-source for others to build on and remix, Fathom and Enable Community Foundation have partnered together to further the mission of the e-NABLE global community. The Fathom team shares a deep passion for 3D printing and finding applications that improve people’s lives.

“These 3D printed prosthetics have an undeniable impact on the lives of children and their families,” said Mihevc. “Fathom has the expertise and technology to help children who otherwise might not have access to this type of mobility and our team is committed to sharing these resources with the e-NABLE community.”

Fathom joined the Enable Community Foundation network to use the team’s creativity and expertise with professional 3D CAD software and additive manufacturing technologies for a cause greater than itself—you can, too! The team encourages designers, engineers, 3D printing companies, web developers and anyone with anything to contribute to join and donate today!

AN EARLY INTEREST IN SCIENCE, ENGINEERING, MATH, AND TECHNOLOGY

After just a few meetings with Fathom Mechanical Engineer Bethany Casarez and Industrial Designer Ava DeCapri, Isabella began to show a strong interest in STEM.

“Isabella is a really curious kid and when we were fitting her for her arm, she asked so many questions that she could probably design the thing herself at this point,” Casarez laughed. “Having a young girl like her so engaged in mechanics and design, it’s been awesome.”

When Fathom joined the e-NABLE network, Casarez and DeCapri were excited to use the company’s resources for a cause greater than itself—the experience was even more impactful than they imagined.

“We’ve seen Isabella start to identify with the community of people using and making prosthetics,” DeCapri said. “Maybe down the line we’ll see her become an engineer or designer! I’m really proud to show Isabella that women are a big part of the science community.”

CREATING THE 3D PRINTED PROSTHETIC AT Fathom FOR ISABELLA

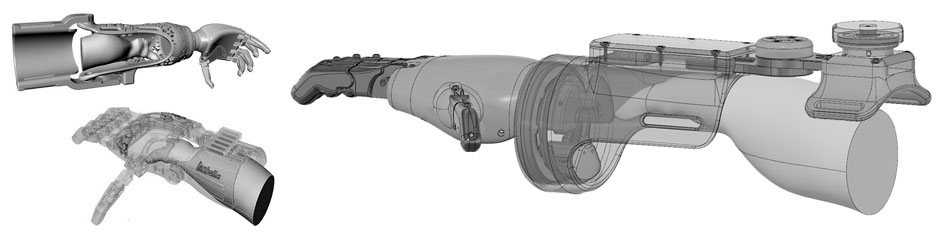

Isabella was born with Amniotic Band Syndrome of the right arm, so the team set out to design an elbow-actuated prosthetic for Isabella, as existing designs available through the e-NABLE community would not work for her. The Isabella Arm was designed for users who lack wrist strength or have a partial forearm.

3D printing’s unique ability to adapt to specialized needs is crucial to e-NABLE’s cause. Thanks to the collaborative development efforts within the e-NABLE community, the Fathom team was able to leverage existing open source prosthetic designs for prototypes.

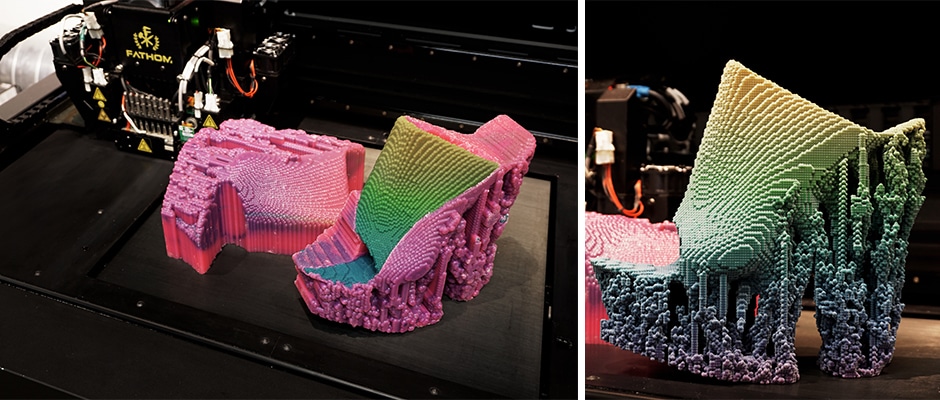

The Fused Deposition Modeling technology utilized in this project is ideal for 3D printed prosthetics. With many production-grade 3D printing material options to choose from, the team opted for ASA, a thermoplastic with great mechanical strength that is UV stable. The material is extremely durable and conducive to the various peripheral features that the team wanted to implement, such as rubber-like fingertips for enhanced gripping capabilities. Decapri also worked with Mechanical Engineer Alexei Samimi to dye the 3D printed parts, transforming the part into a vibrant pink prosthetic that’s safe for Isabella to use on a daily basis.

The team built two prototype prosthetics for Isabella to try before completing a third final design. The first prototype relies on Isabella’s wrist to close the grasp, while the second and third iterations use her elbow strength. The latter two were further developed with Isabella’s relatively limited wrist strength in mind.

Dubbed the “Isabella Arm” by Fathom (download 3D CAD files), the prosthetic was designed for and tested using the uPrint SE and Fortus 450, FDM-based 3D printing systems that utilize engineering-grade thermoplastics and soluble support. Modifications may be required to successfully build the prosthetic on other machines.

The Isabella Arm by Fathom is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License. If you use the design, please provide attribution. If you remix this design, let us know! The Fathom team encourages fellow designers and engineers to adapt it to the needs of others then share your versions with the e-NABLE community. Pay the progress forward.

Credits: The principle designers are Dylan Millsaps (Fathom summer intern), Bethany Casarez (Fathom Applications Engineer) and Ava DeCapri (Fathom Industrial Designer). Video by Jeff Diehl with direction by Elizabeth Griffin-Isabelle (Fathom Director of Marketing) and Silas Alexander (Marketing Communications Specialist). Inspiration and encouragement by Rich Stump and Michelle Mihevc (Principals). Hands-on help from the Fathom production team: Tony Slavik, Drew Price, Kyle Most and Victoria Most. And many others!

Special Thanks: Care Bears & American Greetings, e-NABLE (Jon Schull, John Wong, Andreas Bastian) and Isabella & Family.

To learn more about the e-NABLE community, visit: enablingthefuture.org

PRESS / / MEDIA KIT

For more information on this story, contact Elizabeth Griffin (Director of Marketing) at media@fathommfg.com