Fathom’s Wire EDM surface finishing provides the smoothest finish of any metal cutting method.

Wire EDM Surface Finishing:

What’s Achievable?

Surface finish is often called out on part prints. Sometimes it’s because it influences appearance. More often, it affects how surfaces slide over one another. Bearing surfaces and those used for sealing are examples of where finish is important.

Wire EDM surface finishing is different than the finish produced by conventional cutting and machining. Other cutting processes produce a finish with directionality, caused by the movement of the cutting tool.

At the microscopic level, even ground surfaces have evidence of this “lay”, and it affects how a product performs. Sliding friction is typically lower in the direction of “lay” than across it. “Lay” also affects the long-term durability and performance of seals acting on the surface. With EDM there is no directionality and EDM finish quality can be mirror-like.

Some cutting processes can also alter the physical characteristics of the metal adjacent to the cut, caused by the heat of the cutting tool. This can cause these metal surfaces to become brittle or weak. With wire EDM, the cutting tool doesn’t come in direct contact with the metal, minimizing heat-affected zones.

How Wire EDM

Surface Finishing Works

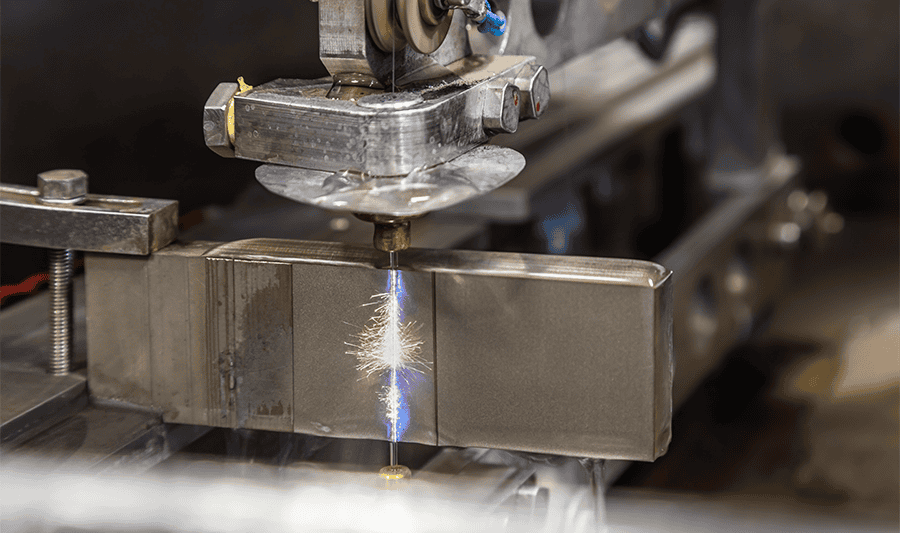

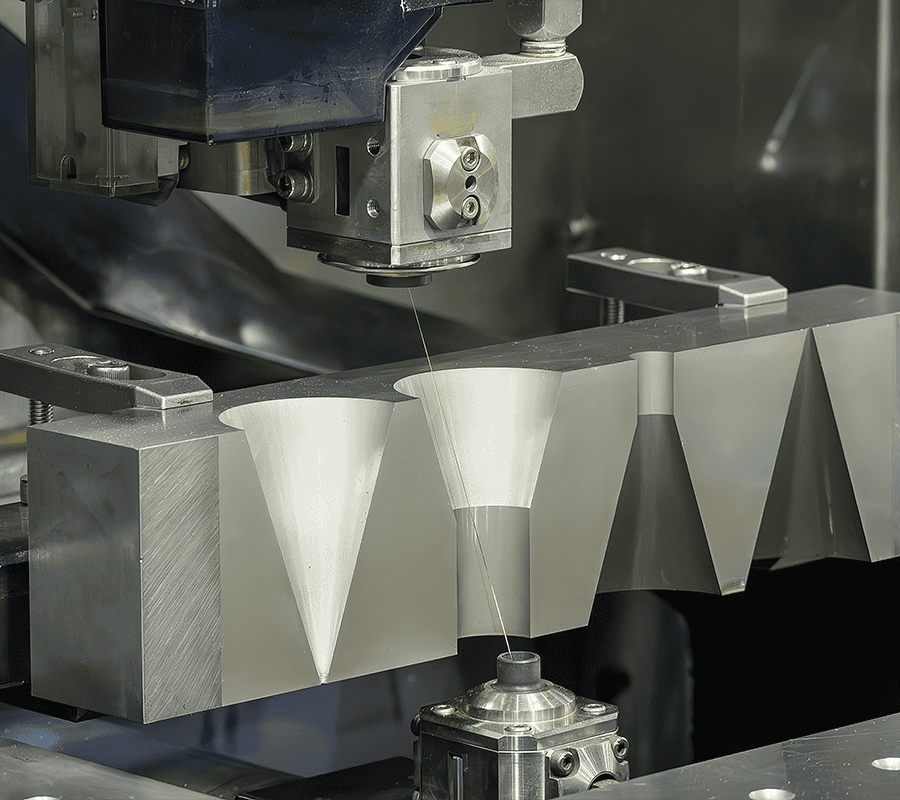

Wire EDM machining cuts a conductive metal with a thin electrode wire that follows a CNC-controlled path. The wire carries a high-voltage charge. The resulting spark melts the material adjacent to the wire, resulting in a very precise cut. A dielectric liquid, such as deionized water, cools the metal and flushes away melted metal particles. That also helps to minimize heat-affected areas.

Wire EDM Surface Finishing

Benefits and Requirements

Wire EDM cutting is unaffected by material hardness. This means a range of exceptionally hard materials are machinable. The only requirement is that they must be electrically conductive. Examples include tool steel, tungsten carbide and Inconel.

EDM

Finish Quality

With wire EDM, surface roughness is inversely proportional to cutting power and speed. In other words, the key to achieving better EDM finish quality is to cut slower.

When a very high-quality finish is required, the usual practice is to follow a high-speed roughing cut with one or more finishing or skimming cuts. As a guide, a roughing pass results in a finish of around 60-120 RMS (about 60-120 micro-inch Ra.) Following up with three skimming passes will bring it down to 15 RMS (approximately 12 micro-inch Ra.)

With more passes it’s possible to approach 5 RMS (4 micro-inches Ra,) although this depends in part on the material density. Wire EDM can achieve a very smooth finish on more dense materials like tungsten carbide. In many applications, using several finishing passes with wire EDM avoids the expense of secondary operations like grinding.

Wire EDM Surface Finishing

Processes

Some finishing may be required on wire EDM parts even though the process can produce a smooth, mirror-like finish. Common finishing processes for wire EDM parts include:

Deburring // Wire and sinker EDM produces features that are burr-free, eliminating the need for costly and time-consuming manual deburring operations.

Painting // Powder coating, liquid coating or e-coating may all be used during the painting process. During powder coating, the powder is electrostatically charged, leaving a scratch-resistant and even coat on the metal part. Liquid coating uses wet paint to coat a surface. E-coating is the process of dipping a metal part into a bath of paint where the part and paint are electrified, causing the paint to adhere to the part.

Transfers // The transfer process uses a heated press to apply a design to a part. Transferring can also be used to add a design that will later be engraved on the part. Transfers are often used to add labels or decorative designs to a part.

Assembly // During assembly, a set of smaller parts are joined together using fasteners or bonding procedures that may or may not be permanent. Assembly is used to make a larger piece from smaller units.

Wire EDM

Specifications and Tolerances

| Material Thickness | Tolerance | Kerf | Part Volume | Set Up Cost | Lead Time ** | Notes |

|---|---|---|---|---|---|---|

| up to 15 inches thick | 0.0002" | 0.009" to 0.016 | 1-200 Is Best | Low | 10-15 days | Conductive Metals, Carbon |

Why Choose Wire EDM Surface Finishing

from Fathom?

There are several reasons why wire EDM from Fathom works well for metal cutting and finishing:

- More effective cutting capabilities

- Capable of small radius cuts

- No direct contact with the metal, minimizing heat-affected zones

- The ability to cut many different types of conductive metals

- The flexibility to cut delicate, intricate parts

- Suitable for everything from prototyping to high-volume production

Why Choose Fathom’s Wire EDM Service?

Accelerate Your Project with Wire EDM Cutting by Fathom

The Fathom team has extensive experience cutting parts with wire EDM and getting the highest quality results.

Our Tempe location is one of the premier shops for wire EDM machine shops in the U.S. and has been producing high-tolerance parts using this technology for over 20 years.

We do wire EDM cutting for customers in a variety of industries, including automotive, medical, aerospace, satellite, solar and firearms.

Let Fathom handle your metal fabrication and prototyping needs, large or small.

Wire EDM

Materials List

- Copper

- Carbide

- Tungsten

- Bronze

- Carbon steel

- Inconel

- Stainless steel

- Hastelloy

- Kovar

- Titanium

- Carbon graphite

- High alloy steel

How to Get

Wire EDM Quotes

Are you ready to get a quote on your wire EDM project? Do you need to calculate costs? Use Fathom’s SmartQuote application for fast quotes on any file.

Fathom’s Locations for

Wire EDM Surface Finishing

Fathom has many US-based locations that offer wire EDM surface finishing:

Fathom has many US-based locations that offer wire EDM, offering nationwide coverage to the entire United States. Fathom’s advanced prototyping and manufacturing services include injection molding, CNC machining, chemical etching, metal 3D printing, and more. We have provided over 200,000 quotes to leading U.S. companies and are ready to provide you with a quote today.

Wire EDM locations include:

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

ISO 9001:2015

NIST 800-171 Compliant

ITAR

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

1401 Brummel Ave

Elk Grove, IL 60007

ISO 9001:2015 Design Certified

TEXAS

1513 Sam Bass Rd

Round Rock, TX 78681

ISO 9001:2015

ISO 13485:2016