With an adoption of additive manufacturing, Fathom’s multi-step approach delivered custom, value-added solutions to achieve filmmakers’ creative vision.

1,000’s

of Specialized Parts

Challenge //

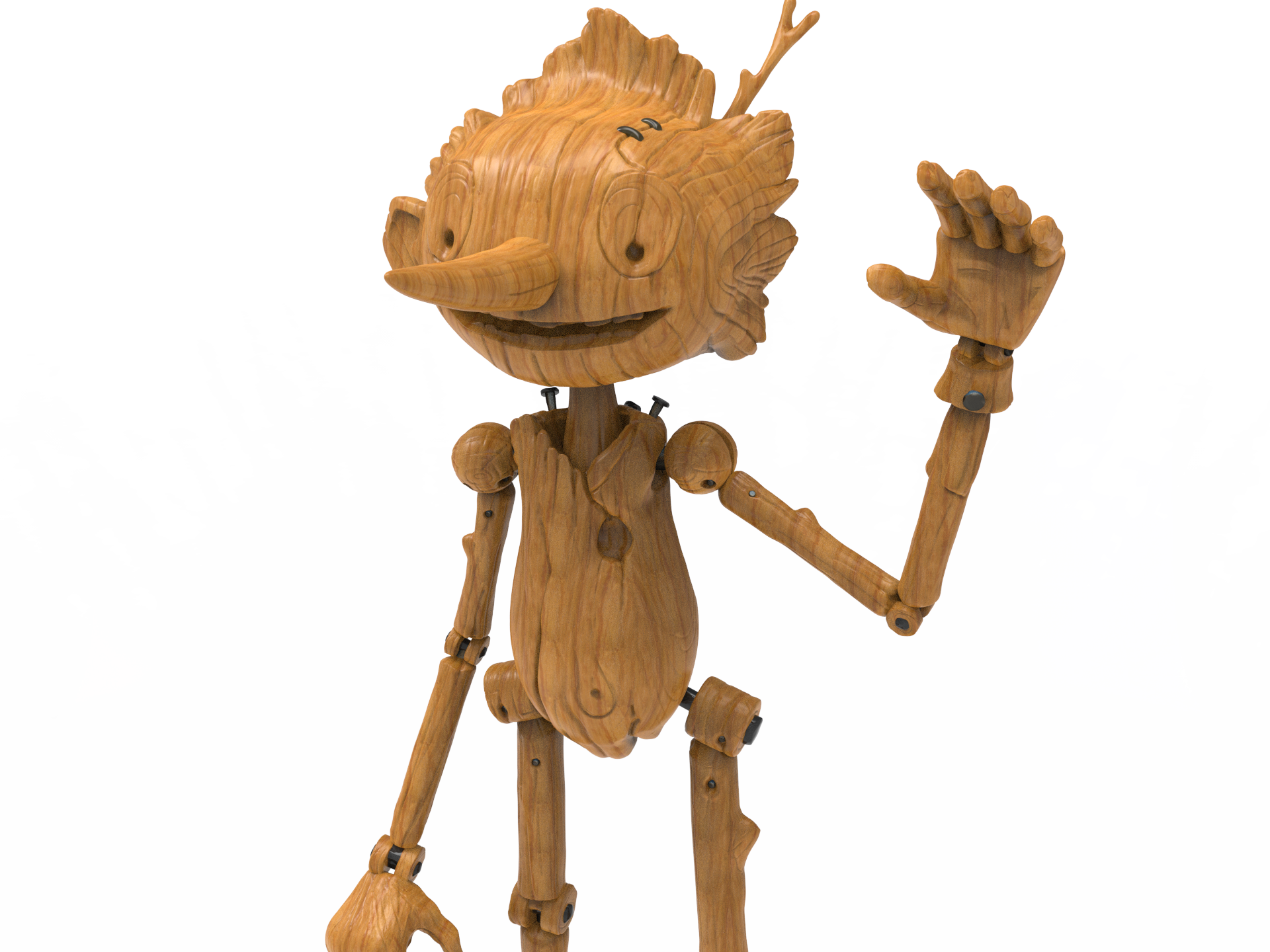

The award-winning Guillermo del Toro’s Pinocchio (Pinocchio) reimagined stop-motion animation, incorporating mechanical components for many of the puppets to provide facial movement and lip sync when moved frame by frame. This innovative approach to puppet fabrication paved the way for a more flexible performance that enabled Guillermo to direct this film in a unique way compared to previous stop-motion features by breathing life into the puppets as if they were live actors.

The use of stop animation required strict continuity for the mechanically operated puppets, especially for the intended shapes and colors of Pinocchio’s nose, head and eyes as well as Spazzatura’s muzzle.

Customized Solutions //

Fathom employed a multi-step approach to achieve the creative vision for the animated feature.

Consultative Planning – Translating Digital Art to Physical Print

- Fathom’s experienced technicians advised on how to optimize the use of 3D printing and the benefits of digital sculpting and painting software for virtual models.

Efficient Iterative Process to Produce Final Prints

- To ensure maximum precision for each print, Fathom defined print diver settings, controlled material batches, and quality control processes as part of the production plan.

- Voxel-level 3D printing also enabled the creation of color models in a 3D digital landscape, providing a seamless conversion to a 3D printed model with texture mapping.

Quality Assurances to Ensure Consistent, Accurate Representation of Multiple Character Features

- Color matching and texture was complex while calibrating the different machines was laborious, requiring an extensive validation process.

- Each batch of parts demonstrated a high level of detail and quality control prior to shipment; branch noses were particularly difficult to build and clean without any chips or warping (as Pinocchio’s nose grew, so did the production challenges).

Domain Expertise in 3D Printing and Industry Software to Create Desired Outcomes

- Fathom’s broad 3D printing capabilities and in-depth knowledge of current software tools created a manufacturing pipeline from animator to technology specialist to the studio.

Talk to an Expert

Working with Fathom means easy access to Additive and Advanced manufacturing experts. Contact us today, and let’s transform the future of manufacturing together!

Additional Resources