2016 East Bay Innovation Awards

Fathom Creates 3D Printed Innovation Awards Trophy, Serves as Judge for Finalists

For the 4th consecutive year, Fathom sponsored the design and production of the 3D printed East Bay EDA Innovation Awards. The trophies recognize and commemorate innovative contributions to the cultural vibrancy of the burgeoning East Bay in a variety of fields.

Following last years nomination and win for Fathom in the category of Advanced Manufacturing, Co-Founder and Principal Rich Stump lends his leadership and expertise as a judge for this years event, hosted by Scott McGrew of NBC’s Press: Here.

“It is such a pleasure to be a part of the East Bay Innovation Awards every year,” Stump said. “Fathom was honored by the recognition last year and I am excited to participate as a judge this year. The East Bay is an area of major innovations that are industry-changing and the EDA plays a large part in creating regional voice and networking resources that strengthen the local economy.”

Fostering Economic Vitality Through Technological Progress

The 2016 Innovation Awards come at a particularly poignant moment in the ongoing economic development and progress of the East Bay, as Oakland was recently chosen as ground zero for a new national computer science program launched in early February, President Obama’s “CS For All” Initiative.

Oakland Mayor Libby Schaaf, speaking to a wide audience of local youth at the program’s introduction, said, “The President picked [Oakland] to launch a national initiative because he knew this city would unleash the amazing talents and innovations you all have.”

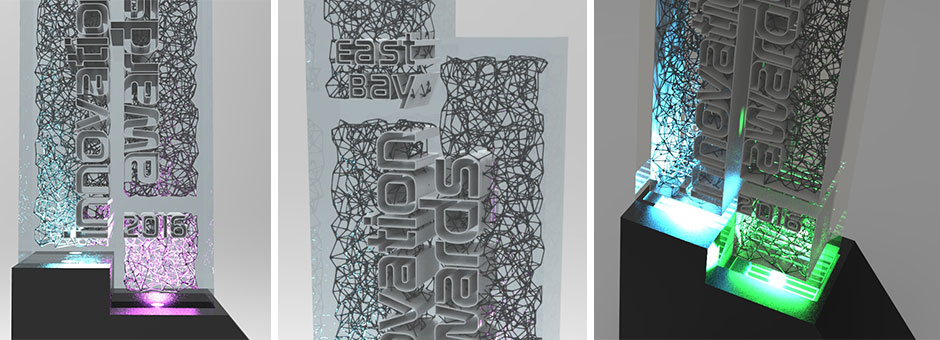

This Years Award—Generative Design for 3D Printing

The 2016 Innovation Award trophies feature a fully 3D printed internal lattice structure set in a semi-translucent body of the award. The lattice highlights similar projects by Fathom related to generative design throughout the past year (check out a table project that utilizes the pattern for support.

“We explored a more generative approach to creating lattice structures inspired by natural materials,” Fathom Industrial Designer Aaron Porterfield, the awards’ creator, explained the motivation for the unique design. “This method of design can be used in many applications and has a really visually dynamic appearance.”

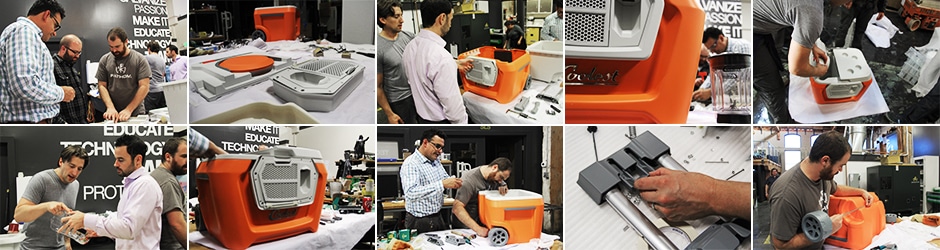

This years design was 3D printed in PolyJet on a Connex-based system from Stratasys at Fathom’s Oakland production center. The interior component was built in nylon on SLS-based additive manufacturing equipment. All production including design, 3D printing, model finishing and assembly was completed by the team Fathom.

You can view also Fathom’s designs for previous years Innovation awards:

- 2014 East Bay EDA Innovation Awards – Multi-Material 3D Printing