LLNL Advanced Manufacturing Lab / / Developing Next-Gen Materials

Fathom Partners with LLNL & Local Leaders in Collaboration for Developing Next-Generation Materials

Lawrence Livermore National Laboratory (LLNL) and the National Nuclear Security Administration (NNSA), along with various industry and governmental organizations from around the San Francisco Bay Area, recently announced the beginning of construction on a $9.4 million facility called the Advanced Manufacturing Lab (AML), where LLNL employees will work side by side with industry leaders and experts.

Located in the Livermore Valley Open Campus, the 13,000-square-foot facility is intended to act as a focal point for the forefront of manufacturing research and innovation (see building render below).

According to Deputy Director Tom Gioconda at LLNL, This new multidisciplinary lab in LVOC will provide a hub for (science and technology) development, which is important for the future of the Livermore Lab, as well as a vibrant research environment for the commercial sector. This is one of those moments in time where 10 years from now, you will look back and say, I was a part of that.

As a prominent research institution and global 3D printing thought leader, LLNL has contributed many breakthroughs in the fields of additive manufacturing and materials science to date. With its new facility, LLNL is looking forward to continuing that trajectory in partnership with industry leaders and top researchers from around the region.

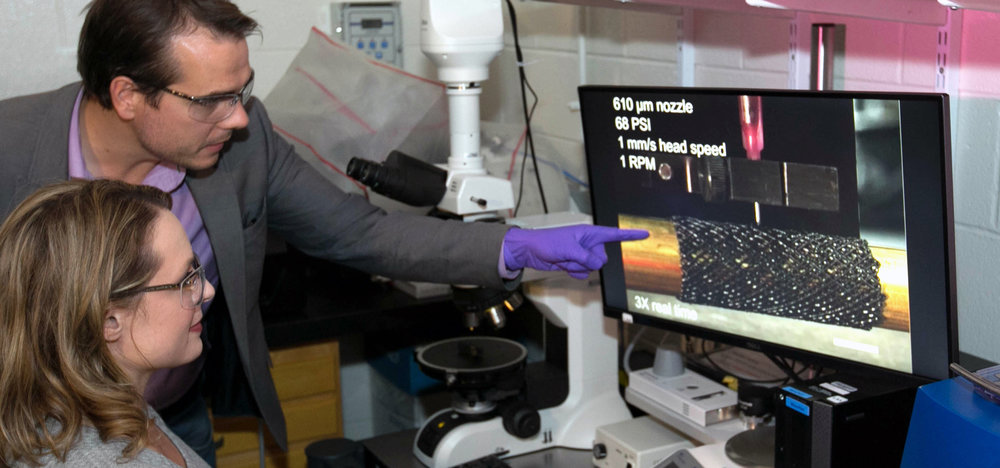

Photo Credit / / LLNL—Pictured Above—Two Researchers Developing Programmable 3D Printed Materials

This initiative builds on LLNLs extensive experience with additive technologies and materials. Focus for all involved in AML includes decreasing manufacturing costs, as well as manufacturings environmental footprint, while improving the quality and specificity of products available for all applications.

The new AML is an exciting step forward in our materials and advanced manufacturing portfolio, said LLNLs Additive Manufacturing Initiative Director Chris Spadaccini. It will better enable us to work with industry and academia to spin out Livermore-developed technologies while simultaneously learning from some of the best groups in the external community.

Fathom is proud to be a partner of LLNL and involved in AML. The advanced manufacturer is committed to continue its collaboration on research and development projects in the field of additive manufacturing well into the future.

Fathom Co-Founder Rich Stump—pictured above—also sees the new facility as a step in the right direction, one that will further broaden the advanced manufacturing community.

By developing new materials and processes, it allows for the technology to be driven into commercial applications, Stump said. We can put people here and access the Labs expertise, the tools, the knowledge and combine it with our knowledge of industry to be able to identify and solve those commercial problems.

To start a conversation about a project or discuss a quote for 3D printing, CNC machining, urethane casting, rapid tooling, injection molding, contract research and development, concept development (design and engineering support) and managed services, send us a request for quote. Fathom is also an authorized partner of Stratasys. Get a quote for a professional 3D printer today!