Sheet Metal Production Made Easy

Majestic Metals by Fathom provides sheet metal fabrication services that are fast, reliable and to spec.

Majestic Metals by Fathom provides sheet metal fabrication services that are fast, reliable and to spec.

We can help you achieve your production targets for high-quality sheet metal components with quick turnarounds and exceptional quality.

Our comprehensive capabilities include:

Got a Question?

Let’s Talk!

We can help you achieve your production targets for high-quality sheet metal components with quick turnarounds and exceptional quality.

Our comprehensive capabilities include:

Got a Question?

Let’s Talk!

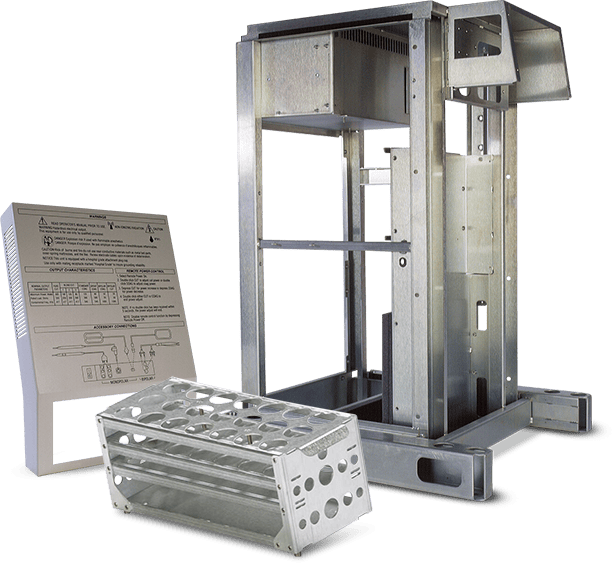

Sheet metal fabrication is the process of cutting, bending, punching and welding flat metal sheets into shapes to create functional parts. We use specialized equipment to cut, bend, roll, form and assemble sheet metal parts into finished products.

We produce metal parts in a variety of sizes, from tiny, complex brackets to large panels and doors. We work with a variety of materials, from aluminum and stainless steel to exotic alloys. What do these components have in common? They start out as flat metal pieces.

Sheet metal fabrication is the process of cutting, bending, punching and welding flat metal sheets into shapes to create functional parts. We use specialized equipment to cut, bend, roll, form and assemble sheet metal parts into finished products.

We produce metal parts in a variety of sizes, from tiny, complex brackets to large panels and doors. We work with a variety of materials, from aluminum and stainless steel to exotic alloys. What do these components have in common? They start out as flat metal pieces.

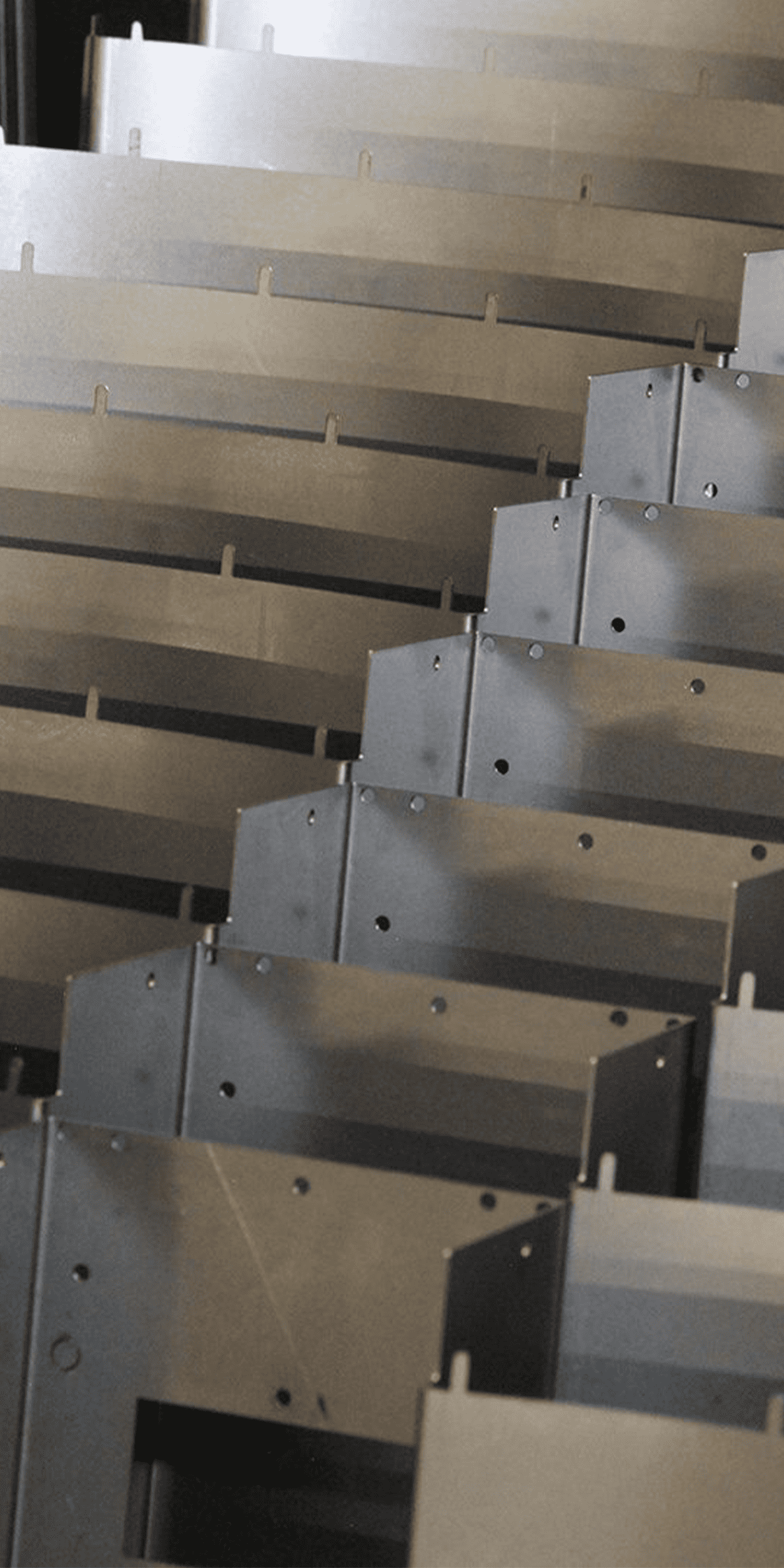

Majestic Metals by Fathom brings a value engineering approach to every sheet metal production project, ensuring that your parts can be produced cost-effectively and quickly. Our team of experts manages every step of the process – from concept and prototyping to production and finishing.

Majestic Metals by Fathom utilizes the latest automation to provide close-tolerance precision laser cutting, punching, forming and welding fabricated components in many complex shapes and sizes.

Laser Cutting // Our experts specialize in laser cutting. It produces intricate and complex parts with precise cuts and high-quality edge finishes. It can eliminate the need for custom tooling. Our lasers can cut .010-.50″ thick materials, +/- .005” with the possibility of tighter tolerances based on project specs – ideal for aluminum, steel and stainless steel.

CNC Punching // Our CNC punch presses can accurately process standard features and complex shapes into sheet metal to meet your most exacting requirements. We can also produce special features such as countersinks, beads and louvers. We can run up to 60x120x33 in. Tolerances: +/- .005” with the possibility of tighter tolerances based on project specs.

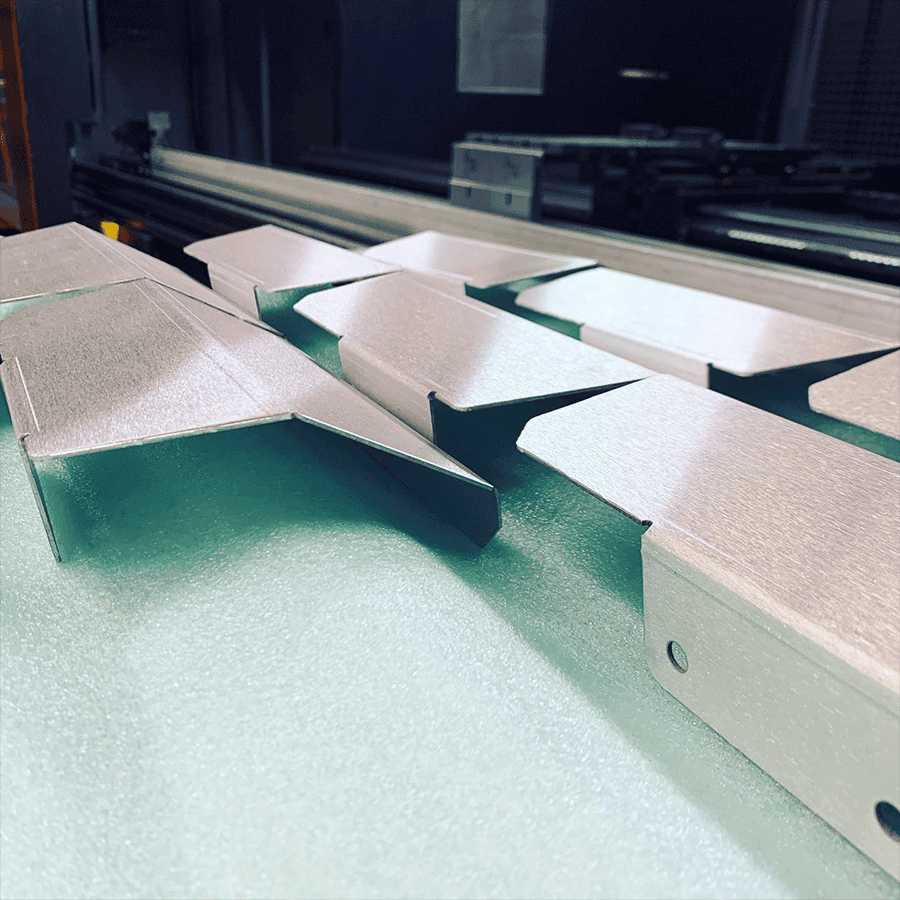

Press Brake // We partner with a world leader in machine tool manufacturing to employ the latest technology for processing. 13 machines. Max Part Length: 12’. Max Tonnage: 220.

Welding is an art that requires a skilled operator. Majestic Metals by Fathom welders have decades of expertise, which translates into high-quality welds, every time. We are welding experts with experience in a variety of industries, types of parts and requirements.

MIG/TIG Welding // MIG uses a solid wire that is machine-fed to the weld area. TIG uses a non-consumable electrode and a hand-held filler rod to form the weld. We offer automated and manual welding, depending upon project needs. Our team has decades of experience with arc, MIG, TIG, and laser welding.

Spot Welding // Spot welding involves applying pressure and heat from an electric current to the weld region to join two or more metal sheets.

Hardware // To save you time and factory space, we can add various types of hardware to your fabricated parts (like pem nuts, weld nuts, nuts and bolts, rivets, and fasteners), meaning less post-processing work for your project.

Once your parts are fabricated, they may require one or more finishing steps. With Majestic Metals by Fathom, you don’t need to outsource it. We do it all for you. We’re a one-stop shop for sheet metal production and finishing.

Mechanical Assembly & Kitting // We offer assembly and kitting in-house. Whether your part requires installing hardware using automated or manual processes, our experts will ensure your part meets your exact specifications. By delivering fully finished components to you, we save you time, money and factory space.

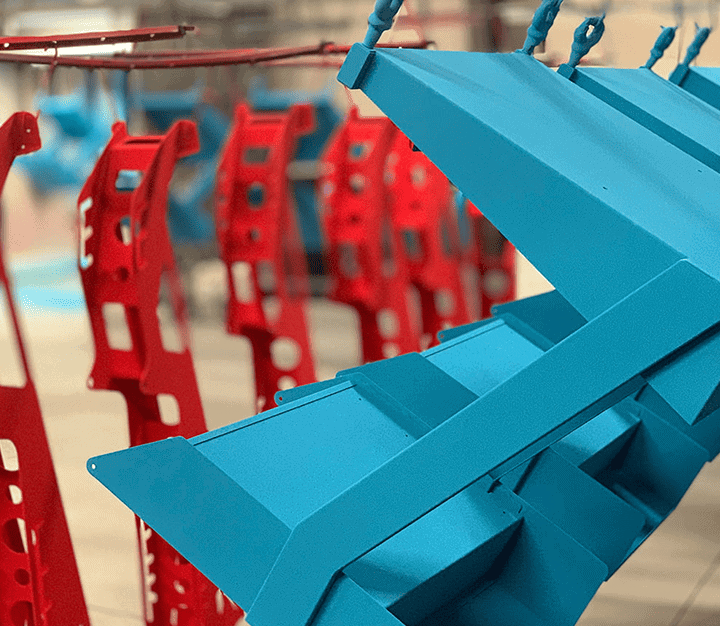

Finishing // If you require your parts painted in custom colors, we can meet your finishing needs, including painting, powder coating and screen printing.

Post-Machining // Our CNC machining centers allow us to put post-mill features into your sheet metal components while also maintaining our fast turnaround times.

Our Customers Appreciate Our

98% On-Time Delivery Rate!

“Quick response time for RFQ, excellent lead time for rushed order and quality parts were manufactured and delivered on-time.” — Manufacturer of Compressed Gas Storage Systems

![]()

Industry Applications

Many industries choose Fathom for its sheet metal fabrication services, including medical, defense, aerospace, electronics, automotive and industrial companies. No matter what the industry, our team can meet the technological and manufacturing challenges your project demands.

Aerospace // Aerospace parts often require high accuracy and tight tolerances. Our team delivers parts for the aerospace industry that are durable, reliable and meet exacting specifications.

Automotive // Every finished part that departs our facilities will meet the rigorous standards of the automotive industry. You can rely on Fathom for sheet metal parts that are both reliable and safe.

Defense // The defense industry requires high precision and efficiency standards for weapons, vehicles, and more. Fathom is an ITAR registered manufacturer and defense contract supplier who can support all your military and defense needs for sheet metal components.

Electronics // The electronics industry requires parts with tighter tolerances and finer surfaces. Whether your electronics project needs a simple or complex design, Fathom delivers.

Industrial // Parts for industrial applications must be reliable and durable. Using our all-in-one manufacturing services, we can assist you from design to finishing your sheet metal parts.

Life Sciences // The medical industry sets high standards for both quality and cleanliness. Sheet metal fabrication is used to make a variety of medical devices.

VSi Parylene (VSi) provides advanced protective coating technologies for industrial and consumer electronics, aerospace and medical applications. Fathom played a key role in the launch of its POD Factory machine, which featured a sophisticated and challenging design. Fathom’s integrated, technology-agnostic approach and rapid response team enabled the customer to condense its product development cycle in half.

Prototype to Production //

Why Our Customers Choose Majestic Metals by Fathom

Fast Turnarounds // We can help you get your prototype parts into production quickly – so you can bring your new products to market faster.

Design for Manufacturability (DFM) // Our highly skilled team can help you optimize the design of your part to uncover and solve design problems, increase part quality and reduce production costs.

In-House Custom Tooling // We can build tooling to meet your requirements. Because we provide this service in-house, you don’t have to worry about delays caused by an outside tooling vendor.

Lights-Out Production // We can produce parts in quantities of 100 to 10,000. Our in-house sheet metal production equipment can run lights out. That enables us to provide economical production solutions and faster turnarounds on your time-sensitive projects.

A Long Track Record of Success // Majestic Metals was founded in 1979. During the last 40-plus years, we’ve built an exceptional reputation for service, quality and speed.

Certification & Compliance // We’re ISO 9001:2015 and ITAR Registered, and certified in APQP and PPAP.

![]()

“Very responsive and customer oriented. Cost competitive, willing and equipped to take on a variety of volumes, materials and complexity.” — Contract Manufacturer for the Aerospace/Defense, Industrial and Healthcare Sectors

Additional Resources

Precision manufacturing

from coast to coast.

HEADQUARTERS //

1050 Walnut Ridge Drive

Hartland, WI 53029

877-328-4668

ARIZONA

444 W. 21st St. Ste. 101

Tempe, AZ 85282

480-966-2300

COLORADO

7770 Washington St.

Denver, CO 80229

303-288-6855

ILLINOIS

1207 Adams Drive

McHenry, IL 60051

815-385-7500

1401 Brummel Ave

Elk Grove, IL 60007

847-952-8088

MINNESOTA

13758 Johnson Street NE

Ham Lake, MN 55304

763-755-7575

NEW YORK

1920 Slaterville Rd.

Ithaca, NY 14850

607-277-7070

401 W. Shore Blvd.

Newark, NY 14513

315-331-7680

TEXAS

1513 Sam Bass Rd.

Round Rock, TX 78660

512-255-1477