Q.

What is molding?

What is molding? Molding is a manufacturing process where a pliable or molten material is forced into a hollow mold to create a desired shape.

Fathom is hiring for multiple positions across our nationwide sites! To see all open positions, click here

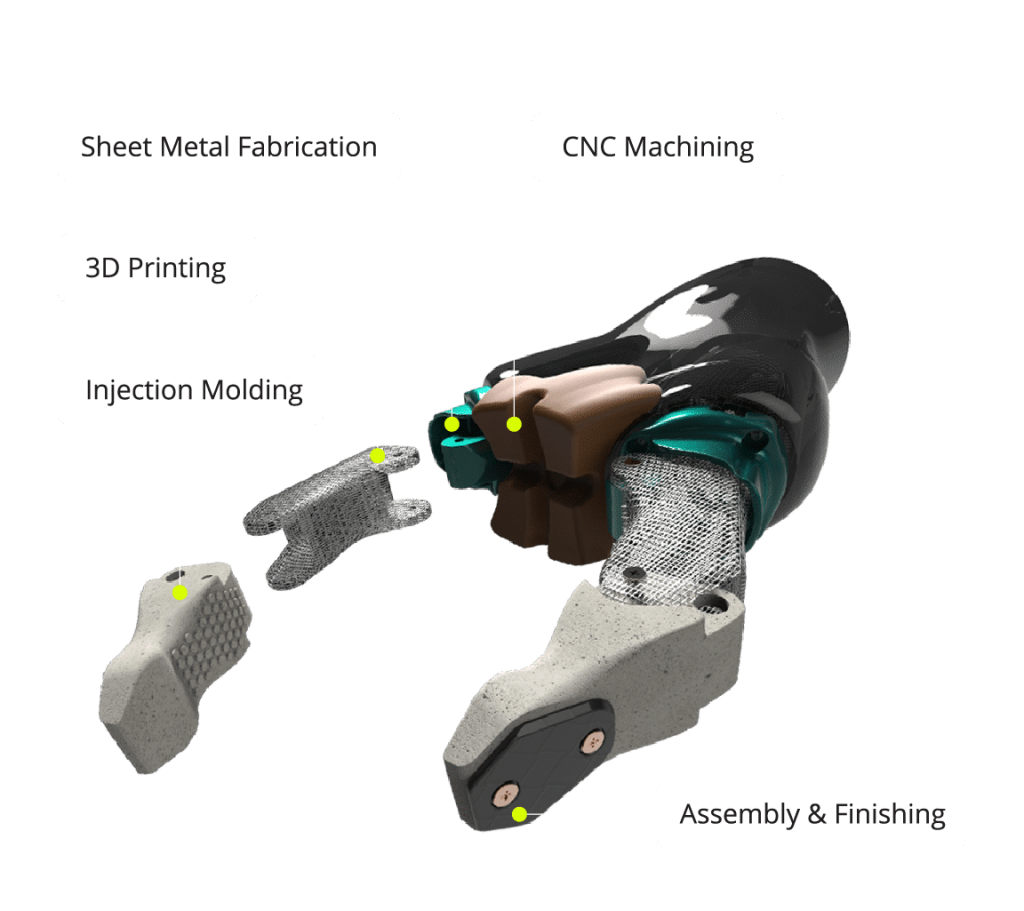

From prototyping to production, Fathom delivers precision manufacturing at scale. Explore our comprehensive suite of U.S.-based services—from CNC machining and molding to advanced metrology and outsourced solutions—trusted by leaders in aerospace, medical, robotics, and beyond. Every project is backed by expert support, strict certifications, and scalable technology.

Fathom provides full-spectrum manufacturing solutions tailored to your product journey—from early-stage concept to scalable production. Our services are built to accelerate timelines, reduce costs, and ensure quality across every phase.

Helping you solve your biggest manufacturing challenges – with White Glove Service

Leverage our deep engineering expertise and white-glove support from prototype to production to bring your new products to market faster.

Tariffs. Instability. Margin Pressure. Fathom Edgeworks was built to outsmart the chaos and outprice the competition.

We specialize in high-stakes sectors where precision, speed, and reliability matter most. Explore how Fathom supports innovation across regulated and fast-moving industries.

High-precision where performance and compliance matter most.

Quality controls for regulated environments.

For tight tolerances, reliability, and scale.

The consistency and control for advanced fabrication.

Precision for reliability, repeatability, and production readiness.

Accelerating ICT infrastructure builds with less risk—from prototype through ramp.

All other industries beyond our five primary markets.

Stay ahead with expert content, guides, and case studies that support smarter decisions and better manufacturing outcomes.

Fathom customers love our hands-on approach to engineering and production. Read the stories.

Check out our industry events, facility tours, and expert-led manufacturing experiences.

Tour our facilities, get an inside look at state-of-the-art manufacturing technologies and more.

A place for expert insights, industry trends, and practical manufacturing tips from the Fathom team.

Find quick answers to common questions about our capabilities, processes, and getting started with Fathom.

Learn more about Fathom’s mission, people, and footprint across the U.S. We’re committed to excellence, innovation, and supporting our customers at every stage of the product journey.

Fathom is a U.S.-based advanced manufacturer built to serve engineers with speed, scale, and precision.

Stories, announcements, and milestones shaping Fathom’s role in modern manufacturing.

25+ processes, real production capacity, and a white-glove experience—Fathom delivers more than just parts.

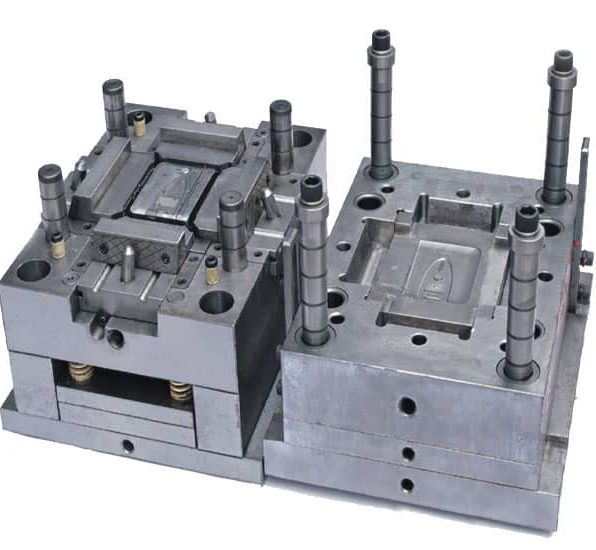

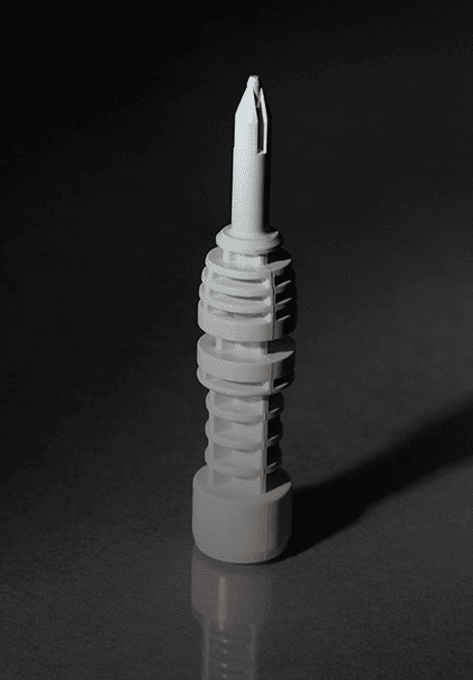

Tooling for molding consists of two halves that are joined together under pressure. Molten material then enters and fills the tool. In other cases, material is placed in the mold cavity and then expands under heat and pressure. Most types of molding require engineers to keep certain factors in mind when designing parts. Specifically, avoid overhangs, sharp corners and changes in wall thickness and incorporate draft for efficient ejection of parts from the mold.

During the molding process, heat and pressure force the material to completely fill the mold cavity. The part then cools and solidifies. In the case of injection molding, cooling channels may be incorporated into the tool to speed this process. A draft angle on the part and tool helps ensure the part can easily be removed or ejected from the tool. For certain processes, curing may be required to complete the solidification process.

Molded parts may go through multiple steps after the molding process is complete. Flashing (excess material that escaped through the parting line between the two halves of the mold) may need to be trimmed. Witness marks caused by gating and parting lines may need to be sanded. Inserts may be molded into the part or heat staked during post-processing. Painting, coating, labeling and assembly are other common finishing steps for molded parts.

Precision molding and hands-on expertise for your most demanding applications

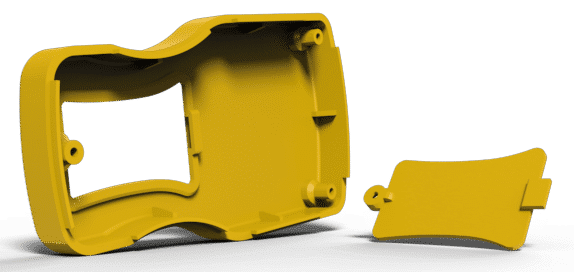

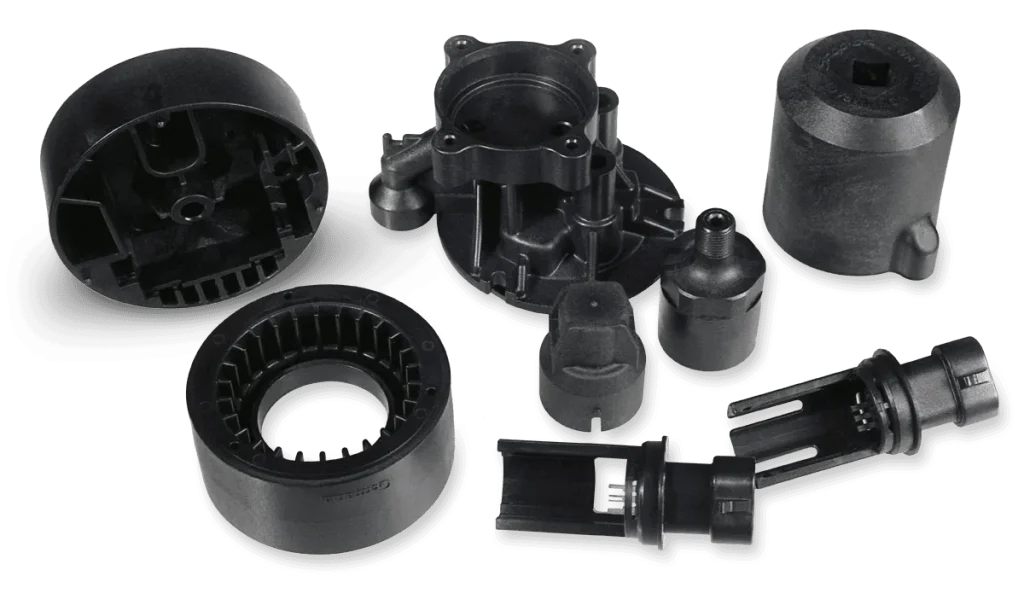

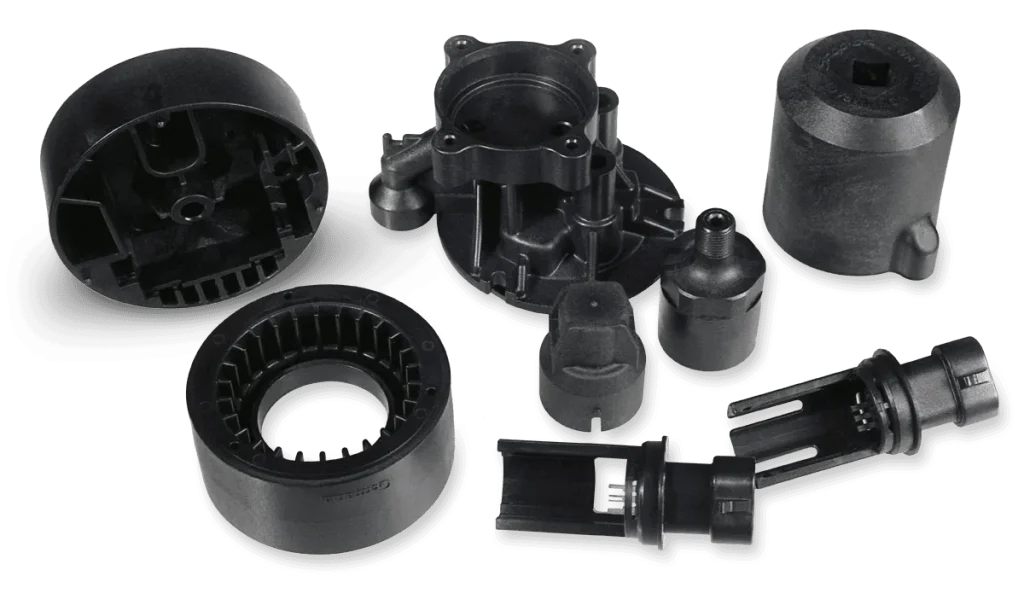

Check out these examples of our molded parts

Fathom customers love our hands-on approach to engineering and production. This personalized approach is reflected in these Molding technology case studies.

What is molding? Molding is a manufacturing process where a pliable or molten material is forced into a hollow mold to create a desired shape.

The best process depends on the project’s needs, including part size and complexity, required production volume, budget and material specifications.

The initial cost of creating the mold is a significant expense, especially for high-precision or complex parts. The cost is often driven by factors like the mold’s required precision, its expected lifespan (number of shots) and the materials and methods used to create it.

Fathom’s rapid tooling service produces steel tooling quickly, with delivery of sample parts in as little as 15 days. Not aluminum tooling, which has a limited life, but hardened steel tooling that is perfect for bridge and low-volume production of parts.

For injection molding, a mold flow analysis simulates how molten plastic will flow into the mold, based on your planned gate locations. It gives you the opportunity to optimise your tool design prior to building the tool. That, in turn, helps assure that it will produce high-quality parts, consistently.

Injection molding is most cost-effective for producing large volumes, typically 1,000 or more parts, because of the high initial tooling costs.

That depends upon the application in which they will be used. Will they exposed to abrasion, corrosive materials or environmental extremes. Do you need to hit a specific per-part target cost? Your Fathom engineer can help you select the right material for your needs.

From early concepts and prototypes to bridge and low-volume production, we’ve got you covered.

We’ll perform a Design for Manufacturability (DFM) analysis to help you optimize your part design for production. Our expert engineers will also identify opportunities for cost reduction in part design, tooling and the proposed production process. Our ultimate goal? To eliminate potential production problems early in your design process.

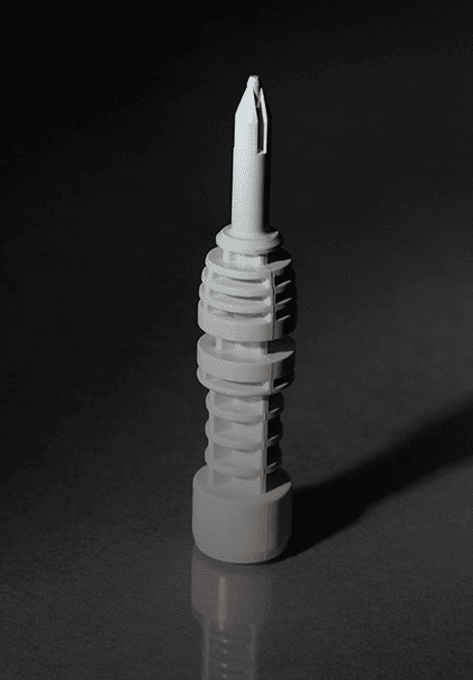

Quickly iterate and finalize part designs using our on-demand manufacturing services. Rapid prototyping services employ digital manufacturing methods. They enable designs to move directly from a CAD drawing to a finished plastic or metal part in a matter of hours or days – without the need for tooling. Rapid prototyping can help you bring products to market faster.

Bridge production can help you solve a number of common problems, including side-stepping tooling delays, meeting regulatory requirements and conducting market research if you’re unsure of demand for your new product. Producing a small quantity of parts enables you to preview a new product to a select audience and make tweaks before you ramp up to full production.

Many third-party manufacturers prefer to avoid low-volume production in favor of long production runs of relatively simple geometries. We specialize in low-volume/high-mix projects. We’re very good at it! Bridge production also makes sense when you’re moving tooling from overseas to domestic production, so you can keep your production line running smoothly.

Every quote is reviewed by an experienced engineer to ensure optimal design, materials and manufacturability, so your part gets made right, the first time.