Nylon Family of FDM Materials

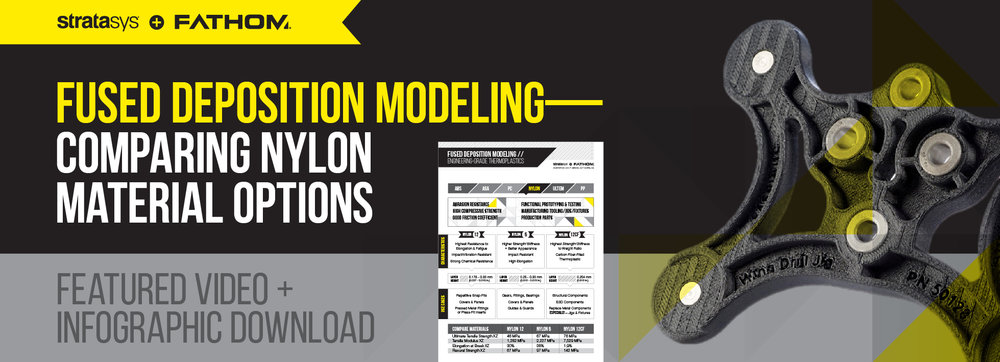

Stratasys offers three types of Nylon materials for fused deposition modeling (FDM) to meet the varying application needs of strength and flexibility—but, when to choose which material? To better help you decide, weve created a material comparison of Nylon 12, Nylon 6 and Nylon 12CF (carbon-filled)—compare characteristics, layer height, use cases and additional information all in one PDF download.

→ Download Infographic / / Nylon Family of FDM Materials

We also recently caught up with Rob Winker of Stratasys who stopped by Fathom’s production center in Oakland to talk about these commonly used thermoplastics—watch the video to learn more about when to use Nylon 12, Nylon 6 and Nylon 12CF. Want to evaluate these materials even further? Download the technical datasheets below.

| MATERIAL DATASHEET | KEY CHARACTERISTICS |

|---|---|

| Nylon 12 | Strong + High Fatigue Resistance |

| Nylon 12CF | Carbon-Filled With Highest Flexural Strength + Highest Stiffness-To-Weight Ratio |

| Nylon 6 | Strong (Impact) + Tough (High Fatigue Resistance) |

VIDEO WITH ROB WINKER OF STRATASYS

VIDEO WITH KAITLYN BAILEY OF Fathom

Many FDM material options have a lot in common, so upload your files today for a quote and speak with an expert at Fathom about which material is right for your application—whether you place a service order with Fathom or want to bring an additive manufacturing system from Fathom in-house.