High-Resolution 3D Printing Small Parts in PolyJet

High-resolution 3D printing is in high demand. The ability to form complex geometries already revolutionized prototyping and product development in industries like robotics, optics, medical devices and electronics—powerful CAD programs and precisely accurate 3D printers and additive manufacturing equipment have made this possible. IN THIS EPISODE OF What Can You Fathom?

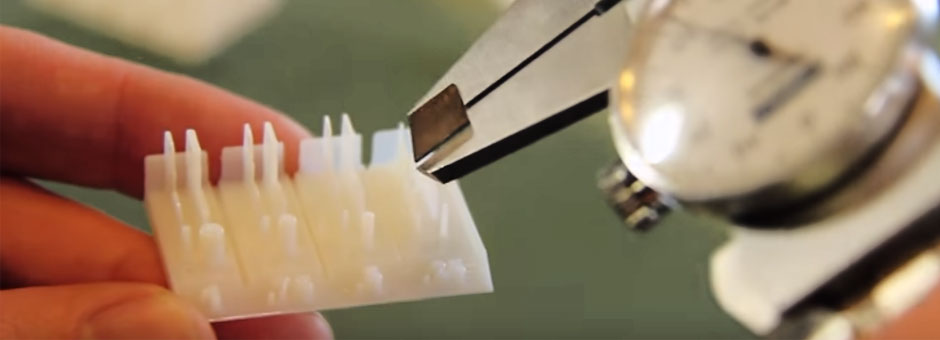

SmartQuote Specialist Ben Bradley examines the advantages, limitations, techniques and best practices for both designing and 3D printing parts that push the minimum size limits of today’s most capable professional and industrial 3D printing technologies. Watch the video to learn minimum wall thickness and feature size recommendations, with a special focus on PolyJet Technology.

Bradley discusses what these terms mean and what designers and engineers should know when creating objects with very small features. He also provides details on how Fathom technicians optimize design files for best results using “tricks of the trade” developed through years of experience and how factors like orientation, matte and glossy settings, material choice and more can affect the success or failure of a given print job. You’ll also get a sneak peek at what Fathom specialists look for when evaluating part files for problematic features.