Multi Jet Fusion //

MJF 3D Printing

- MJF Parts As Soon As 2 Days

- Cost-Effective for Short-Run Production and Prototyping

- Complex Geometries with High Performance Materials

Get a Quote

And connect to Fathom experts

High-Quality Parts Produced Fast

with Multi Jet Fusion 3D Printing (MJF)

Complex, Accurate Parts Made Simple

Do you need complex parts with highly accurate features and isotropic mechanical properties that can be produced quickly? Multi Jet Fusion 3D printing (MJF) is an excellent choice for this common scenario. It can be used to produce functional prototypes and is ideal for bridge production as well as low- to medium-volume production parts.

MJF Parts in as Soon as 2 Days // Get A Quote

How Does Multi Jet Fusion 3D Printing Work?

Multi Jet Fusion 3D printing is a technology that uses powder bed fusion to produce highly accurate, functional prototypes and final parts,

MJF parts start with a thin layer of powder spread across the print bed. An inkjet array in the print carriage sweeps over the print bed, jetting two agents downward into the powder—a fusing agent and a detailing agent. The fusing agent is used to fuse the powder and the detailing agent is used to reduce fusing at the part boundary to achieve greater detail. After the print carriage finishes a pass, the build platform is lowered, more powder is added, and the process starts again.

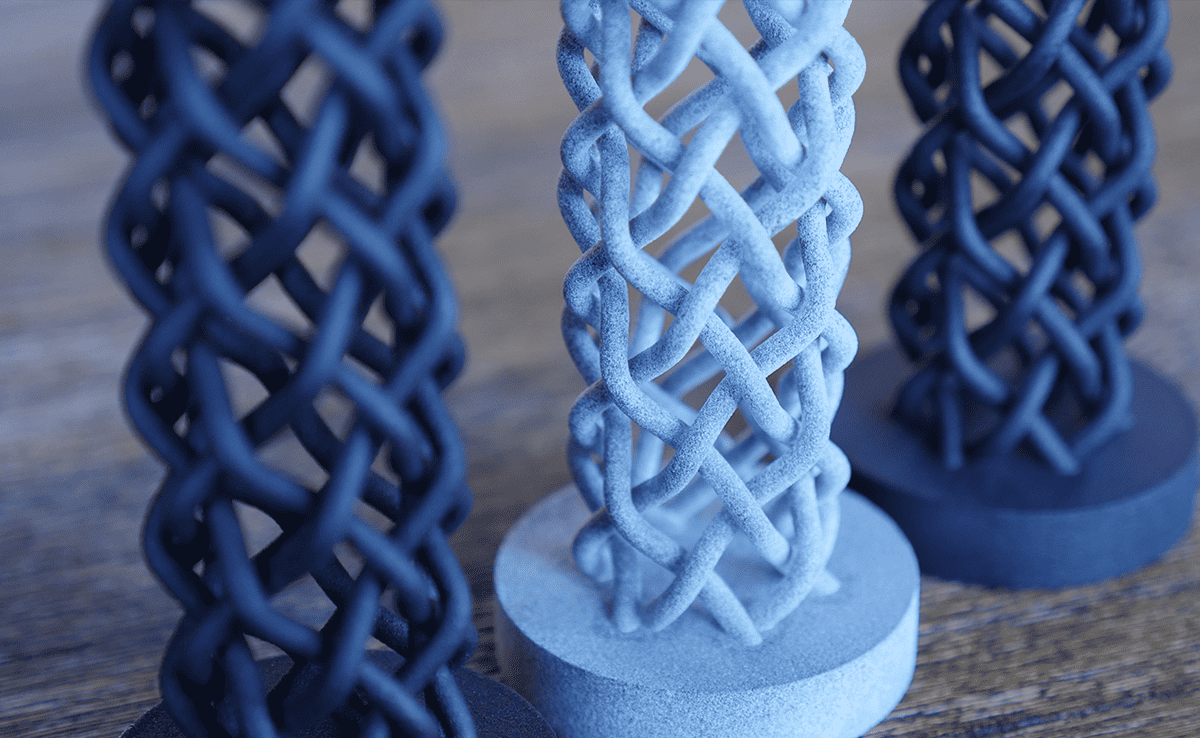

Parts produced using an MJF printing service don’t require support structures, enabling the affordable production of complex geometries and multiple parts within a single build envelope.

Applications of MJF

Parts with smooth surfaces and complex, intricate features can be manufactured using Multi Jet Fusion 3D printing. Common applications include:

- Functional prototypes

- Rapid prototypes

- Bridge production

- Durable end-use parts

- Housings

- Complex and organic geometries

- Parts with fine features

- Parts with isotropic mechanical characteristics

- Parts where a smooth surface is a must

- Low- to medium-volume production parts

Industries where MJF parts are used include:

- Automotive

- Medical

- Consumer goods

What Does MJF 3D Printing Make Possible?

Similar to Injection Molded Parts // MJF can produce parts with a density similar to plastic injection molded parts. They can be processed and machined in similar ways. That makes MJF parts perfect for bridge production.

Print Multiple Parts in a Single Build // Because the powdered material serves as a support structure for the parts as they’re being fabricated, parts can be stacked in the Z direction, enabling you to get more parts out of each build.

Fine Detail // MJF produces thinner layers than SLS and other 3D printing methods, which means MJF parts can incorporate finer detail than some other additive manufacturing techniques.

Affordable // Because of its superior printing speed, MJF is cost-effective for prototyping and low-production parts (up to about 1,000 pieces).

Advantages

Complex Geometries // Fathom’s MJF printing service can be used to print highly detailed and dimensionally accurate parts. That makes it well-suited for producing functional prototypes and end-use parts with unique shapes.

Excellent Surface Finish // Because MJF uses a thin layer structure, it offers one of the smoothest surface finishes of any 3D printing technology.

Produce a Large Volume of Parts Quickly // Multiple parts can be produced at the same time in a single build.

Excellent Mechanical Properties // Parts produced using MJF have excellent isotropic mechanical properties.

Removable Build Volumes // Parts and their build platform can be removed from the printer for cooling. Meanwhile, another build volume can be installed so the printer can begin producing more parts. This unique design enables high-volume production of parts.

More Sustainable // Up to 80% of the powder from MJF prints can be recycled in subsequent prints, more than with SLS.

Disadvantages

Limited Material Selections // Because MJF is a process that’s proprietary to HP, you’re restricted to their materials – Nylon 11 and 12.

Limited Color Options // Parts produced with MJF have a dark gray color, which limits your ability to recolor them.

Avoid Long & Thin Part Features // They are susceptible to non-uniform cooling, which may cause warpage.

What Can MJF be Paired With?

MJF can be used for bridge production – ideal if you’re waiting for your injection mold tooling to be completed – and for small to medium-sized production runs. MJF can be used to quickly and affordably create functional prototypes for new product designs that will later be produced using injection molding.

With our cross-functional engineering expertise, our MJF printing service can help you tweak your part designs so they work well in both environments.

Alternatives to MJF 3D Printing

If isotropic mechanical properties aren’t a major priority for your parts, Selecting Laser Sintering (SLS) is a viable alternative.

If you want parts that can be dyed or painted in a wider variety of colors, SLS or PolyJet may be better choices.

If you want to choose from a wider variety of materials, SLS or FDM may be worth a look.

Traditional Technologies That Can Benefit from MJF

Multi Jet Fusion 3D printing can be used to build part designs that aren’t possible using traditional manufacturing methods such as CNC machining and sheet metal fabrication.

It also enables fast, low-cost production of prototype and limited-run production parts – without tooling.

MJF Materials Available

Nylon 11 and 12 are available for use with MJF printers. Not sure what you need? Talk to a Fathom expert today!

Case Studies //

Robotic Finger

A Fathom engineer worked with an individual with Muscular Dystrophy (MD) to redesign an assistive robot in order to simplify the design while providing an easy route to customization and cost effective low-volume manufacturing. By employing additive, the need for a costly injection mold tool was removed, reliability was improved and additionally manual labor assembly costs were reduced.

Accelerated COVID-19 Testing

In the early days of the COVID-19 pandemic, a major bottleneck to widespread testing was a shortage of nasopharyngeal swabs. In just 35 days, Fathom assisted in the development, testing and production of 3D-printed test-kit swabs, working tirelessly alongside Abiogenix, Harvard University, and HP to ready this life-saving diagnostic tool for use at the front lines of the pandemic.

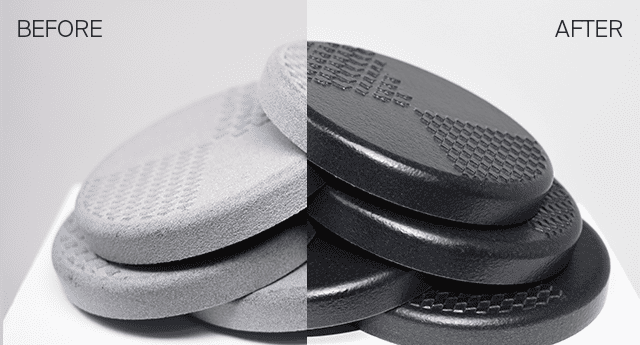

Finishing Options for MJF Parts

Because MJF parts have a density that is similar to plastic injection molded parts, they can also be machined as needed. They can also be drilled to open up small holes that may be hard to produce during the printing process.

Fathom offers these post-processing services for MJF parts:

- Sanded

- Tumbled

- Media blasted

- Vapor smoothed

- Painted (EMI shield)

- Painted (sand and paint, non-cosmetic)

- Painted (sand and paint, cosmetic)

- Painted (customer spec paint)

- Specialty coating

- Dyed

- Plated

- Decals

- Pad printed

- Screen printed

- Inserts

- Post machined

- Assembly

Our craftspeople are ready to meet your MJF post-processing needs. Talk to an expert now.

Vapor Smoothing

Fathom offers AMT’s PostPro3D technology, a smart and automated post-processing solution, as part of our MJF printing service. PostPro3D can achieve a high-quality surface finish that matches injection molding techniques when using 3D printing processes.

Why Choose Multi Jet Fusion?

Affordability

Other than FDM, MJF is one of the least expensive 3D printing technologies available. Its fast print time is also attractive if you need several hundred to a thousand parts quickly.

Bridge Production

MJF can be used for bridge production while you’re waiting for your production tooling to come online or if you’re not ready to commit to spending on a final production solution.

Complexity

It enables 3D printing of parts with fine details and complex geometries.

Why Choose Fathom’s MJF 3D Printing?

Fathom has the expertise and technology to help you meet your needs faster.

If you need short turnaround production, MJF machines are faster than many other types of additive processes. Fathom’s MJF printing service has machine capacity available for Nylon 11 and 12, and can even substitute other additive processes as needed and still ship on time to hit your sensitive deadlines. We are a single source for additive, traditional and other types of manufacturing.

In addition to being one of North America’s leading commercial 3D printing services, Fathom offers domestic and overseas injection molding capacity that can help make your next project launch a success.

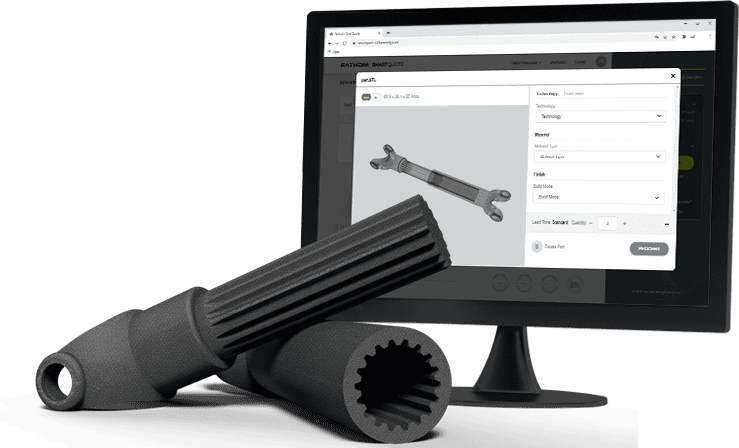

Get a quote on your MJF project today with our SmartQuote platform.